Grinding Rest

This is a grinding rest, made to Harold Hall's design. Harold's website and the documentation and drawings in his book describe this rest in exhaustive detail. Since this is probably the only project I've undertaken without making any design changes, I won't go into great detail about the rest.

The above photos show the parts that make up the grinding rest and a few stages in the assembly process. As you can see, I made the part taking into account all of the updates on Harold's website.

In the book, Harold discusses turning the shaft of a grinder to run true and making some bushes to hold the grinding wheels to simplify swapping wheels. He does this by mounting the grinder on his lathe and using the power of the grinder to turn the shaft. The mini-lathe is way too small to do this, but I thought it was a good idea, so I decided to have a go anyway. I bought a second-hand bench grinder on ebay (for 99p!) and, since I couldn't mount it on the mini-lathe, that left the milling machine.

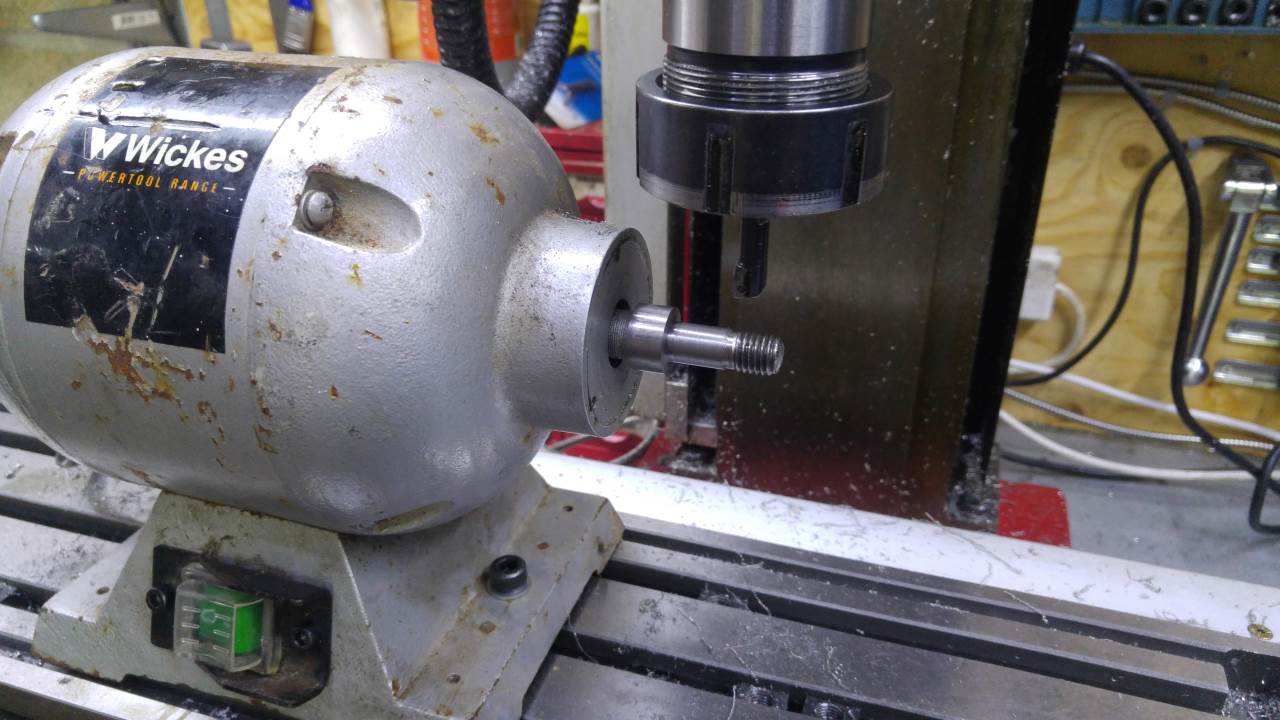

The photos above show the grinder mounted on the milling table.

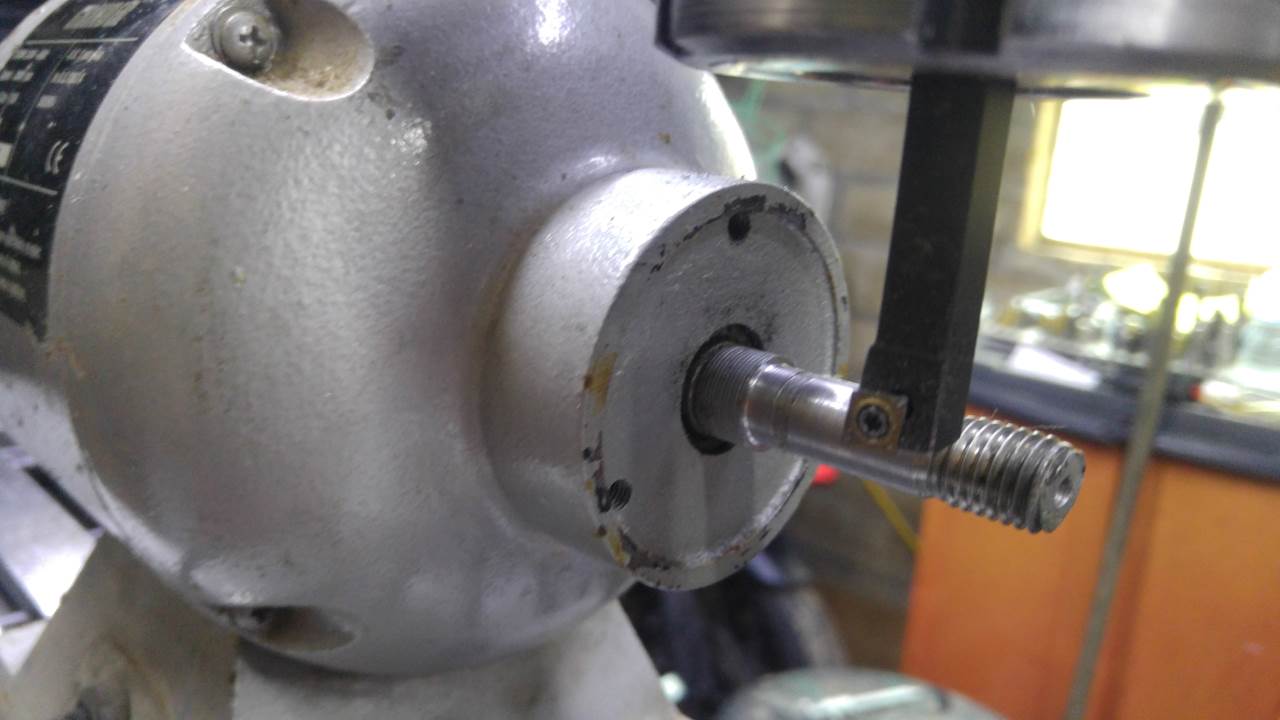

In order to turn the milling machine into a makeshift lathe, I mounted lathe insert tools into the mill chuck and used the power of the grinder to spin the shaft. For one end I used a boring bar (as this was easily held in the mill chuck), but for the other I used a left-hand turning tool with the square shank held in a round collet - this is obviously not ideal, but it seemed to work.

For this method to work, I was using the spindle as a tool-post and hence I didn't really want it to rotate. The simple way I got round this was to use a bungee cord attached to my spindle lock; there was still a little bit of rotary motion in the spindle, but as long as it was held against a limit at the start of the cut, the cutting forces maintained the position nicely.

I bought a sheet of thin steel and drilled and countersunk three holes. These were used to screw the plate to the bench and the grinder was mounted on a piece of wood to raise the height up to suit the grinding rest. I haven't got as far as adding a shield for the wider grinding wheel; this is on my list of things to do and I should probably get on with it!

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.