Grinder Tool Supports

The tool supports that come with most (all?) bench grinders are inadequate for accurate tool grinding, so I replaced them. My supports are made from 6 mm × 75 mm × 120 mm mild steel.

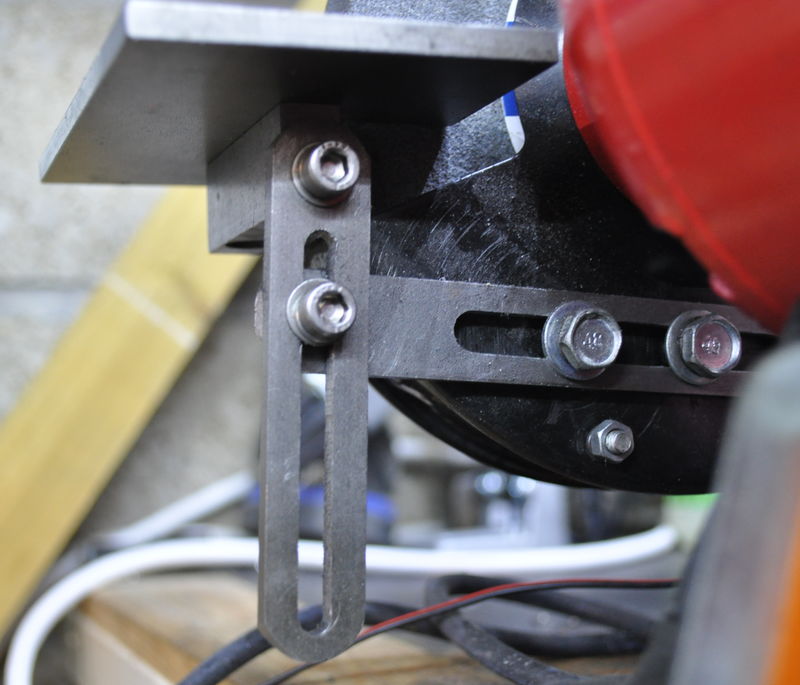

The cut-outs were done using the bandsaw to make the basic shape and a hand-file to get them square. There is a 60 mm bar cut from 20 mm × 12 mm mild steel screwed to the base with M6 cap screws. Two brackets made from 20 mm × 5 mm bar (one is 100 mm long; the other 120 mm) have then been slotted using a milling cutter in the lathe chuck and these are used to attach the support to the grinder. The design is very closely based on the one on this page, except I never quite got round to scribing the angle lines that Mike uses. The plate was made using the bandsaw, file and drill; the mounting plates were milled using the vertical slide on the lathe.

Previous Version

When I first got the mini-lathe, I quickly needed a tool-rest, but I had limited tools (and skills) with which to make one. To tide me over until I was better set-up, this was my initial tool-rest:

This is made from 3 mm thick mild steel, which I cut to shape (roughly 68 mm × 120 mm) with a hacksaw. A piece of 16 mm × 28 mm × 42 mm bar (the dimensions were as found in the scrap bin) is screwed to the back and then this is mounted using the original tool-rest, which has been mounted upside-down and has an extra hole drilled in it for the rest. This was very quick and easy to make and lasted me well. The only limitations were that there was only one of them (I never got round to changing the other rest), that the mounting isn't as robust or adjustable (only one screw) and that it wasn't as thick or as square as the newer version so couldn't be used ar a reference for my threading tool grinding jig (or later, my tangential tool grinding jig).

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.