Portable Workbench Build Process

Page 44 of 67

Posted 27th March 2021

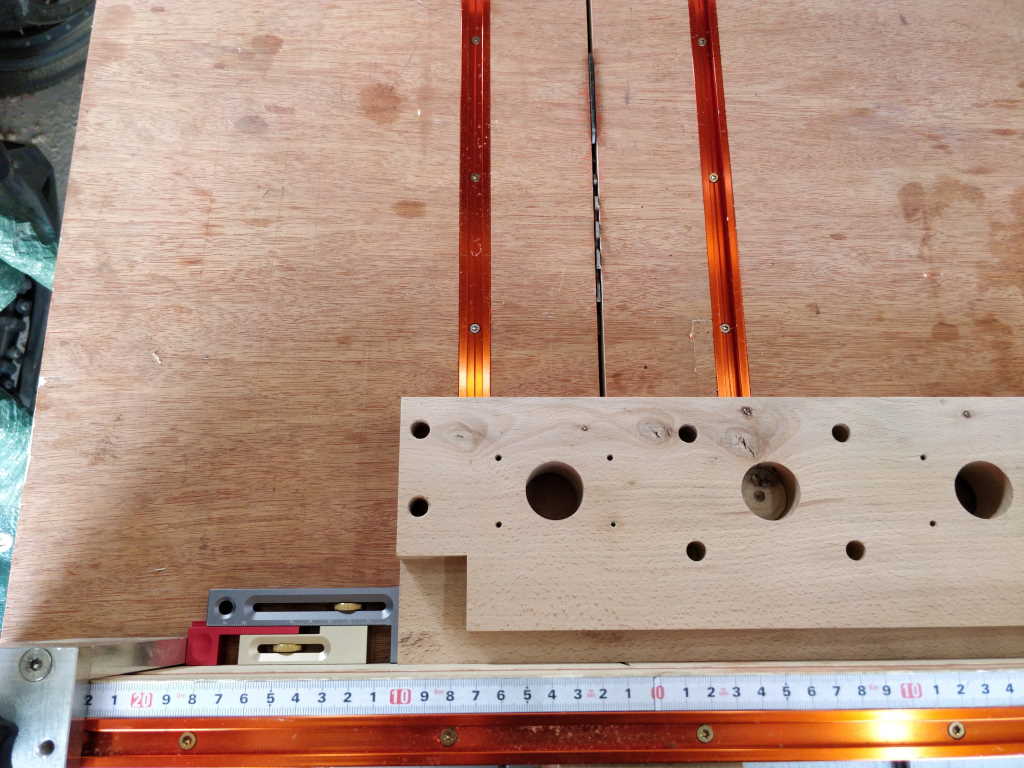

With a small lump in my throat, I set my cross-cut sled up to take a big chunk out of the fixed jaw of the dual-screw vice:

Having cut round two sides, using the little "kerfmaker" knock-off to get the right width, I used my baby router plane (one day I'll find an affordable big router plane for sale!) to clean up the bottom of the groove:

This little router plane doesn't have any built in height adjustment, so I set it on a couple of feeler gauge pieces and dropped it into the groove:

The slot looks much better after routing:

I could then check the fit:

This little insert (which won't be glued into place so it can be removed when not in use) gives a right-angle reference for lining up dovetails, something like this:

It needs a fair bit of tidying up before it's complete, but hopefully you get the idea. In practice I'd probably put something under the tail board (and lift the pin board up accordingly) to reduce the risk of the knife cutting into the moving jaw of the vice.

Page 44 of 67

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page