My Woodwork Workshop

My woodworking workshop area is very small. Half of my single garage is occupied by the metalworking area and a quarter of the garage is occupied by a motorcycle. That leaves the remaining quarter of the garage (an area of about 2 m × 1.5 m) for woodwork. The lack of room is very restrictive, especially in the winter when I'd like to have the garage door shut for warmth, but need to stand outside in order to (for example) comfortably cut material held in the vice.

I used to work with power tools a lot, but in 2022 I made the decision to sell my table saw and try to use hand tools more. That has led to me finding a great deal more enjoyment in woodwork as it's quiet, dust free and safe. Having got to grips with using a smoothing plane, it also means that I rarely have to use sandpaper any more, which is a massive benefit as I hate sanding!

Tool Storage

I really like having tools mounted on the wall and visible. In the workshop I use a mixture of plywood and OSB (oriented strand board) for this, but plywood works a lot better as I like to draw around the tools (so I can see at a glance what's missing) and the pencil lines are easier to see on the plywood. As you can see in the photos here, I've made good use of my 3D printer to make quite a few custom tool holders to help mount tools on the wall.

Since moving my metalworking lathe tool holder storage panel to be ceiling mounted, it has also made the rear side much more accessible and so I use this space to store three of my larger saws.

I had run out of wall space elsewhere in the workshop and it occurred to me that the space immediately above the petrol tank of the motorcycle wasn't being used, so I attached (via a double French cleat) a piece of plywood to one of the joists. That gave me two more areas of "wall-mount" storage, so I was able to add lots more tools.

Even with all that "wall" storage, I still have lots of tools kept in drawers!

The Bench

My bench is made from three layers of 18 mm plywood sandwiched together. When making the bench I had no way of clamping something this big, so I glued the three layers together and then drove screws through from the underside. Once the glue had dried, I removed the screws to allow me to drill holes in the bench wherever I want.

I've drilled quite a lot of holes in the bench. The holes are all 20 mm diameter and are spaced on a 96 mm grid so that I can use the various "MFT" accessories that are designed for this sort of hole spacing. There's a length of T-track set into the bench. This serves two purposes. Firstly: it can be used for (relatively lightly) clamping things to the bench while working on them. Secondly, it's positioned such that when a length of guide rail is placed against a particular row of dogs fitted into the bench, the blade of my track saw runs in the middle of the T-track, thus providing clearance under the blade.

As you can see in the picture above, the grid of dog holes extends onto the jaws of the woodworking vice (which I inherited from my grandfather). This gives a few different options for clamping parts while giving access to the whole of the top surface. For short pieces, I can clamp them length on like this:

Where the parts are a bit longer, I can use a dog as a planing stop but clamp the sides of the boards using the vice:

Where the length of the board is such that I don't have dog holes in the right place, I can simply use a clamp as an end stop:

For planing, I usually just use a simple piece of plywood with a notch cut in the end. This has the advantage that it holds the board rigidly enough for hand planing, but allows the piece to be lifted out and examined without having to loosen a vice or any clamps:

The space under the bench is filled with a variety of things, most notably a large chest of drawers and a rubbish bin. I was concerned that small parts might fall through the holes in the bench and be lost. Thankfully, I have a metalworking lathe and so I decided to do something about it. I had found a piece of 25 mm 303 stainless steel in a skip at work, so I put it in the lathe chuck and machined lots of these little dog hole fillers:

The thread through the middle is M8. The countersunk screw that is attached in the bottom stops very small pieces falling through the threaded hole. The threaded hole makes it easy to pull the dog hole fillers out of their holes and also allows more options for clamping things down (either just with screws through holes into a few dogs to prevent lateral movement or by fitting a screw from under the bench to hold the dog filler in place and then using the remainder of the thread to clamp something firmly down).

As the end of my bench goes right up to the garage door, there isn't space for a tail vice (for clamping timber along the length of the bench). Most of the time that's not a problem as I either leave it loose or use the "doe's foot" (the piece of wood with the notch in). However, sometimes it is useful to clamp the work-piece more rigidly (especially when planing away a lot of stock) and for this I made a dog-hole tail vice, which works really well.

I've also made an additional portable bench that can be placed on top of the main bench or elsewhere for more flexible working options. You can read about that bench here.

Woodwork Machinery

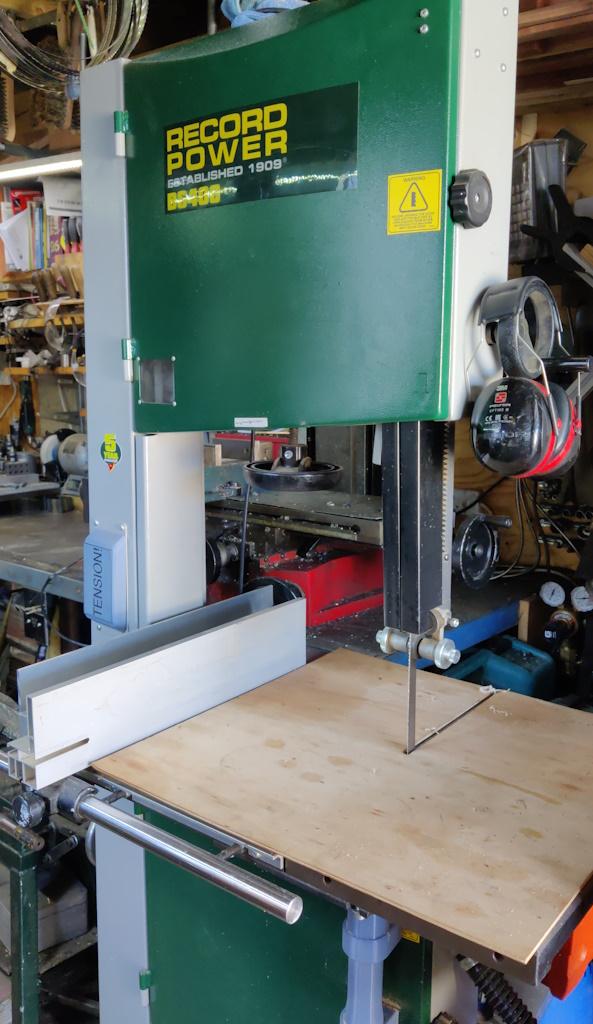

Bandsaw

If I had to go down to having only one woodworking machine in my workshop, I wouldn't hesitate to pick the bandsaw. Resawing by hand is a chore and the bandsaw makes it easy. It can also serve as a (sort-of) thicknesser in that, having planed one side of a board flat, it will cut a second side parallel to the first and at close to the desired thickness. You can then plane the second side smooth and parallel very easily.

I generally try to only use the bandsaw for resawing: other sawing operations are done by hand. Occasionally I'll do a long rip cut or a curved cut with the bandsaw but that really is very infrequent. Nevertheless, since I resaw quite a lot of wood, I wouldn't want to go back to not having a bandsaw. This is in stark contrast to the table saw that I used to have: I have never regretted selling the table saw and I think doing so helped me become a better woodworker.

Wood Lathe

This is a woodturning lathe that I made over the course of about a month in February 2024. It was made from material I had lying around in my (admittedly quite well equipped) metalworking workshop; the sizes of the stock that I had inevitably affected the design choices in lots of ways. I don't especially enjoy woodturning but I like having the lathe available so that I can use it when round objects are required for other projects.

Thicknesser

The thicknesser gives me the ability to reduce the thickness of boards (as the name implies) and plane a second side of a board parallel to the first. It doesn't directly allow me to plane the first side of a board: the power tool that would do that is called a surface planer (known in America as a "jointer"). There is a big difference between the level of difficulty of hand planing a single side to be flat and planing a second side to be flat, parallel to the first side and with the board the right thickness. I'm reasonably comfortable with doing the first of these jobs (or can use my router sled or, with a sled, the thicknesser), but getting the second side parallel and exactly the right thickness is much more difficult and that's where the thicknesser comes in.

Having said that, as I've got more experienced with hand tools, I've been using the thicknesser less often. Having the bandsaw has made a difference here in that if I've got a lot of material to remove, I can resaw with the bandsaw (leaving the board close to parallel) and then it doesn't take much work to finish the job with a hand plane. The bandsaw is much quieter and less dusty than the thicknesser.

I made a trolley for the thicknesser with some "wings" to support long bits of material and a sub-table to try to reduce snipe. You can read about it here.

Routers

I've got two routers, a small hand-held one that takes 8 mm and 6.35 mm (1/4") shank cutters and a large one that can take up to 12.7 mm (1/2") shank cutters. I've had the large one for a while and have used it for odd DIY projects, but since getting the small one I now only use the large one in my (semi) home-made router table. I've made a router sled to help with machining flat surfaces on pieces of wood and a router extension to allow a longer reach for the small router (mainly for use on the sled).

I try to avoid using routers (or "screaming monsters" as someone I know likes to call them!) as they're noisy, dusty and relatively dangerous. Achieving the same effect with hand tools is far more satisfying and enjoyable in my opinion.

Dust Collection

I have a Nilfisk Aero 26-21 vacuum cleaner as my only dust collection means. I made a dust box with a cheap cyclone to make this work much better with less frequent bag and filter changes.

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.