Portable Workbench Build Process

Page 49 of 67

Posted 28th March 2021

With all that epoxy setting, there isn't much I can do for the rest of today, but I thought I'd get on with one little outstanding job that could be done without touching any of the epoxied pieces: sorting out the bore in the spherical seating washers I bought.

There isn't much material to hold on to in the lathe, so I decided this was a job for my home-made soft jaws (made out of some hex bar stock I bought on ebay a while ago). Brass is an odd material for soft jaws, but when I was looking for some very large hex stock, there was a local ebay seller selling a bit off and it was cheaper than buying a length of steel from a steel supplier.

I started by clamping a bit of scrap in the soft jaws. The diameter of the scrap was chosen to minimise the amount I had to take off the soft jaws (to prolong their life).

With the jaws firmly clamped I could then machine a recess of the same diameter as the washer.

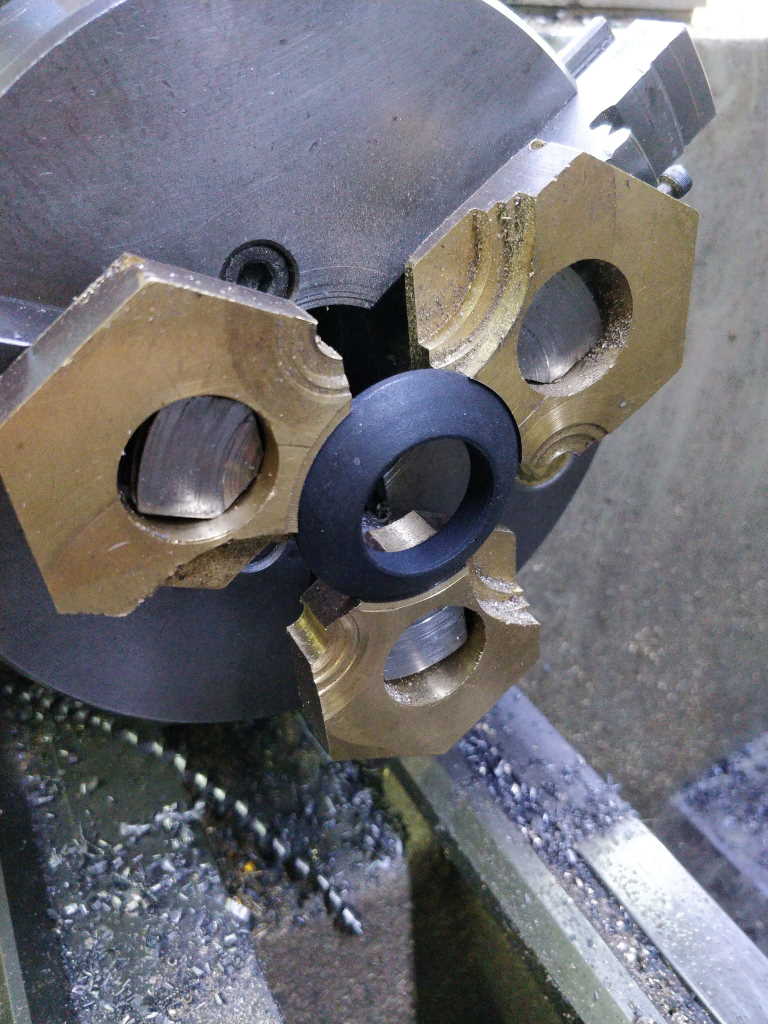

The washer then sits against the back of the recess and is held firmly on the perimeter:

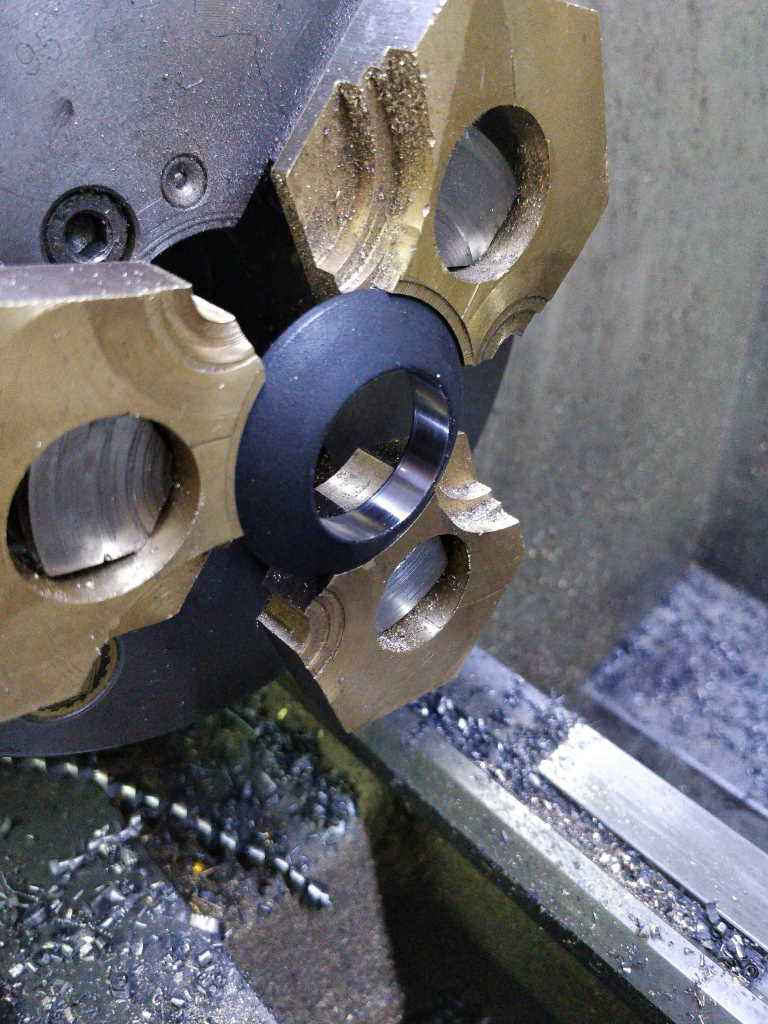

Machining the bore was straightforward as I wasn't aiming for a very precise fit: it just had to slide over the flanged part that sits on the threaded rod.

While I had the soft jaws fitted and set to the right diameter, I decided to mount the convex washers and machine the face. They had a slightly rough finish and I figured it would mar the brass slotted bushes quite quickly without touching up.

On the first one I did I made two mistakes: I started the facing cut with the cutter very close to the piece and I forgot to switch the power feed from turning to facing. As a result, I took a light cut on the outside bore. I usually keep the cutter a little way away from the cut - that way if I have the power feed going the wrong way it just passes by the outside of the part. I was more careful on the second one!

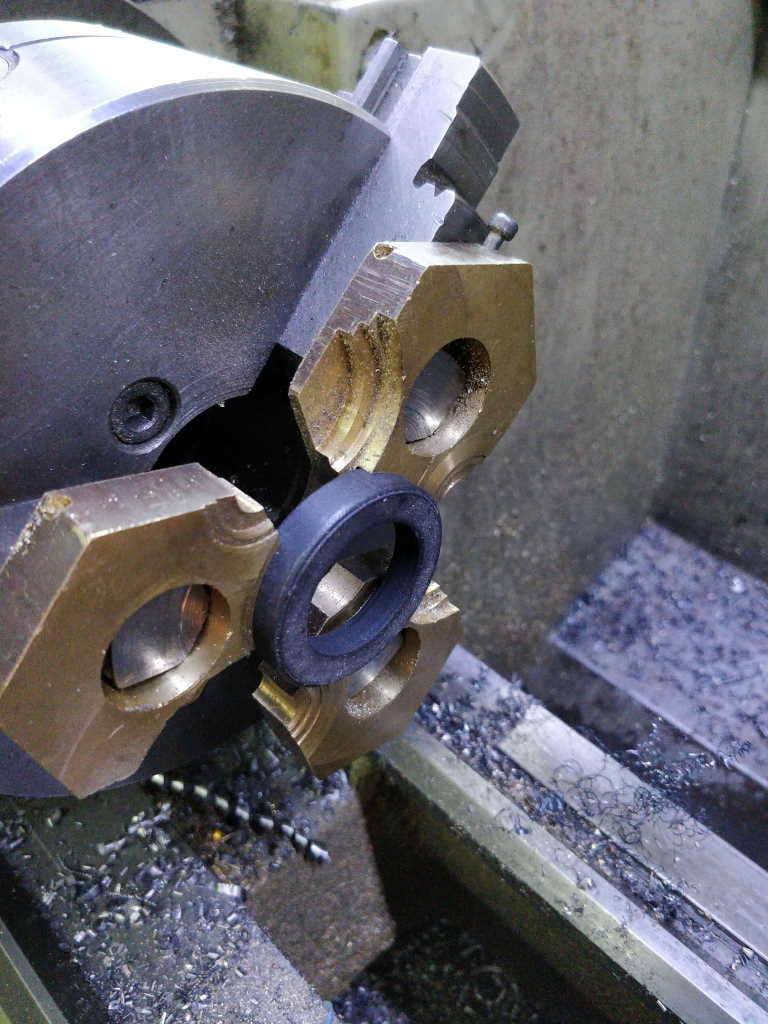

You can see the result of my mistake on the right-hand most piece in this picture of all four pieces:

The parts then got a dunking in cold blue for a few minutes before rinsing in water.

The finished result after a quick air line dry and before coating with oil and leaving alone for the coating to harden.

The cold blue has hidden most of the evidence of my earlier mistake: you can still see it if you're looking for it but it's far less obvious now.

At the moment I can't think of anything else I can do on this until the epoxy has fully cured (14 hours according to the packet), so that's probably it for the day.

Page 49 of 67

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page