Portable Workbench Build Process

Page 14 of 67

Posted 13th March 2021

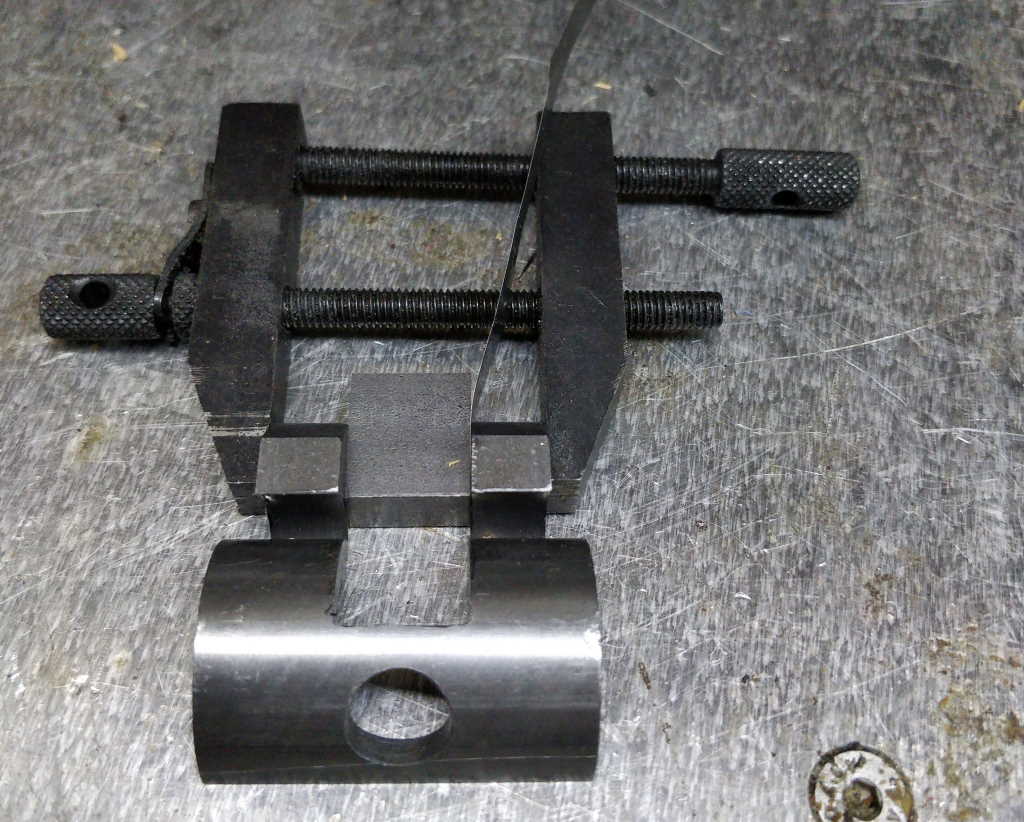

I started the welding with the half-tube. I used the hinge block from the nut as a spacer for the two hinge blocks for the tube. I added an old (and rather battered) feeler gauge in the middle as a spacer to be sure that it would all move after welding. I've got loads of bits of feeler gauge as I bought 3 cheap sets (to supplement an existing good one) and cut them up when I had a mini-lathe and no quick-change tool post: they made it slightly easier to set the height of the tool in the tool post. I don't use them for that any more, but they come in handy now and again as a spacer.

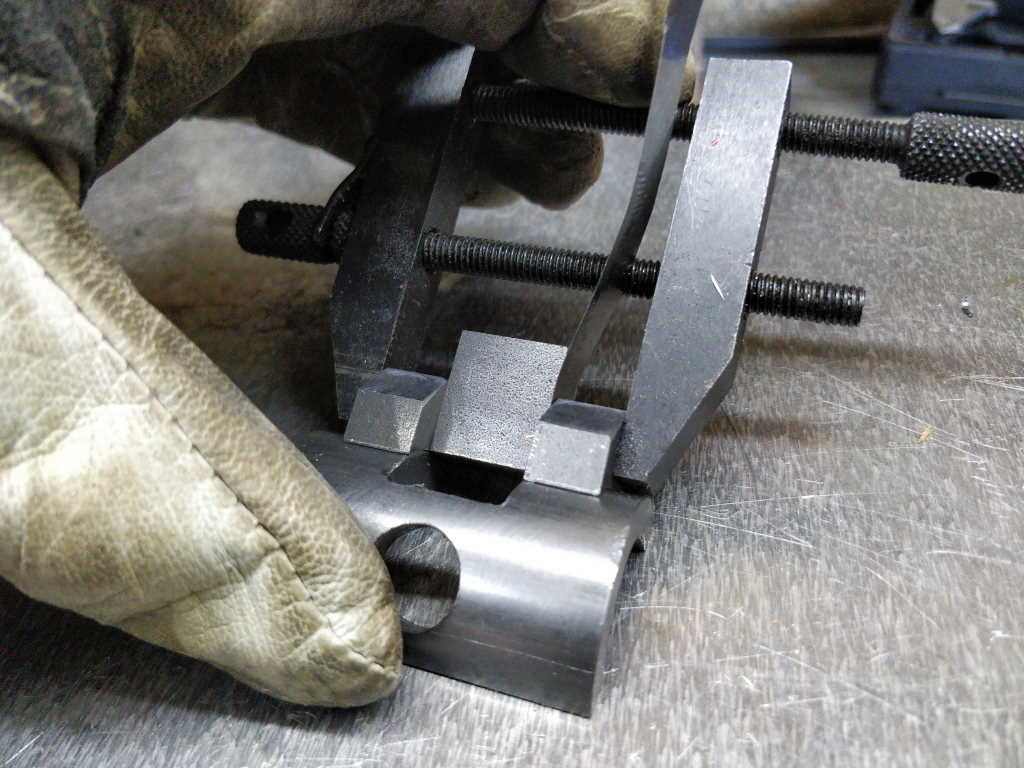

I then held the two pieces together in my hand while I tacked the two hinge blocks onto the tube. No filler rod for these tacks as I don't have three hands, but it's only got to hold for long enough that I can put some proper welds on.

Tacked in place…

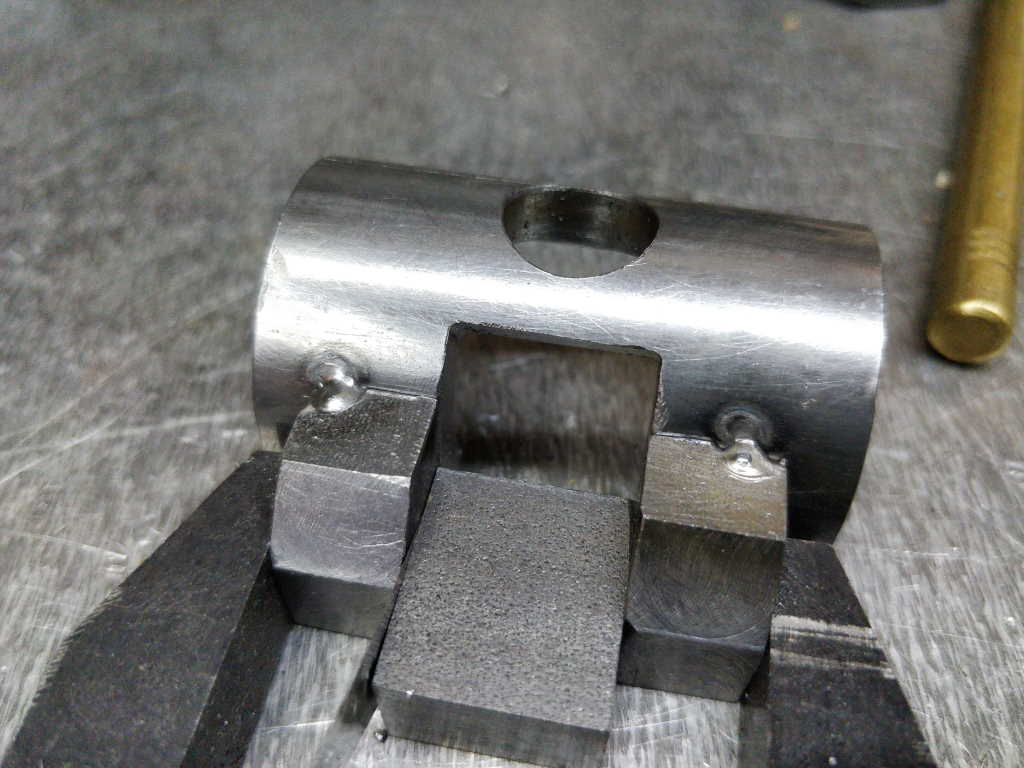

… and welded - note that I didn't weld on the inside of the hinge blocks to be sure that the weld beads wouldn't get in the way of the hinge operation. Spot the mistake...

Page 14 of 67

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page