Portable Workbench Build Process

Page 21 of 67

Posted 15th March 2021

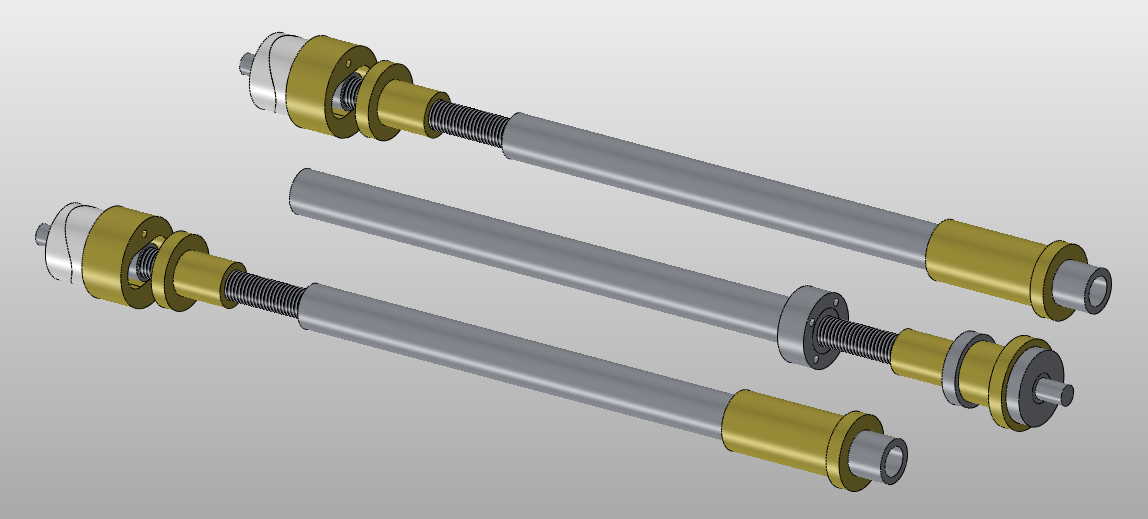

Most of the rest of the parts will be made entirely on the lathe. This is all of the turned parts in the project (excluding the aluminium hand wheels, which will also need a bit of tweaking to modify the central hole):

The long ones are the simplest: three bits of threaded rod with a small plain section turned on one end of each and three bits of 30 mm OD, 20 mm ID tube cut to length (and maybe faced on the lathe for neatness). I'll start with the brass bits:

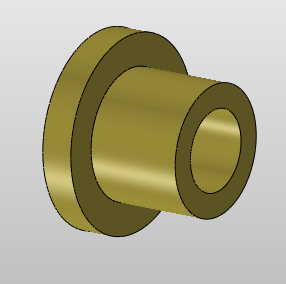

As you can see from the picture, most of these (and one of the steel parts) are variants of the same idea, a simple flanged bush like this:

Most of the other parts are just tubes.

There's lots of variation in all the dimensions, but the process of manufacture is going to be much the same for all of them, so I won't include many photos. I'm going to start with the rail slide bushes for the standard vice (the long ones near the bottom-right of the pictures above). Of all the parts in the design, these are probably the most critical: if they're too loose, the vice will "rack" badly when tightening or in the extreme it could jam as the jaws are pulled in out of parallel. If they're too tight, the vice won't move at all. As soon as these are made, I'll put them in the fixed jaw and attach the rails to the moving jaw and see how it all feels.

After filling one of my bins brim full with nasty bronze swarf, I fitted one of the other bars of skip "brass" in the lathe and did a quick test cut:

Much better! That should be much more pleasant to turn when I get started on the rail bushes.

I also received the hand wheels in the post today. They'll need a bit of machining to open up the internal hole, but otherwise I'll pretty much use them as is (still debating whether to paint them black - I hate painting!). When I ordered them I was debating whether to go with aluminium or cast iron and went with aluminium for cost reasons. Having seen how much all the bits I've made weigh, I think the choice of aluminium may have been a very good one - I just entered some approximate density figures for all the parts in the CAD model and it estimated 28 kg for the finished bench!

Page 21 of 67

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page