Portable Workbench Build Process

Page 31 of 67

Posted 20th March 2021

The threaded sleeve was then mounted in a collet block on the milling machine and two holes were spotted and drilled. These will be used with an angle-grinder style pin spanner to tighten the sleeve onto the threaded rod.

Similarly, I mounted the washer in the mill vice and milled a couple of flats:

These are all the parts that make up the bearing for the standard vice:

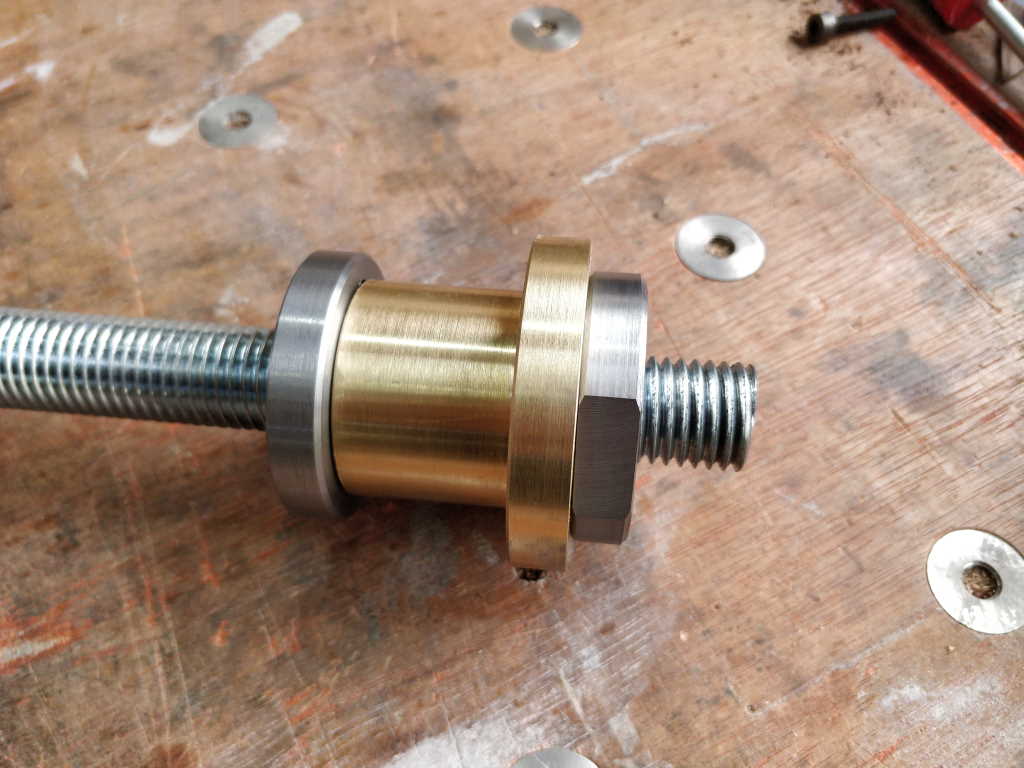

Here they are mounted onto a bit of threaded rod to show how they fit together - in this set-up, the brass part can spin freely.

This is what they look like in the moving jaw - the brass part will be glued into the moving jaw but the other parts will be free to rotate.

Here you can see the pin spanner holes in the threaded sleeve and where they'll sit on the inside face of the moving jaw. The face of the threaded sleeve is slightly below the surface of the beech.

Page 31 of 67

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page