Portable Workbench Build Process

Page 33 of 67

Posted 21st March 2021

I started this morning with a bit of a tidy-up and then sorted out the other two hand-wheels. I didn't bother taking photos of that process as it was exactly the same as the first hand-wheel.

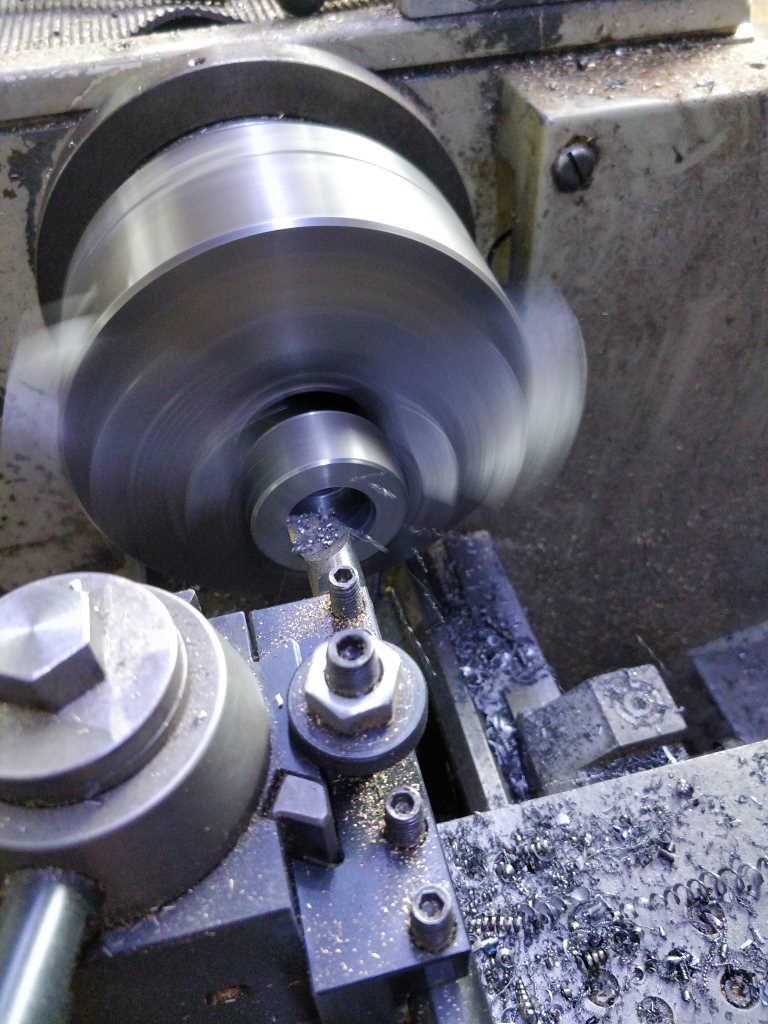

I then fitted a cut-off bit of 50 mm EN1A into the chuck:

I faced the end, chamfered the corners and then spotted the centre hole.

Then it was up through the drill bits as usual, stopping at 25 mm.

I then bored it out to be 30 mm, to fit the bits of tube I'm using in this project.

I moved the tool-post round to an angle and chamfered the ID under power for this one rather than using a deburring tool by hand. No particular reason.

I then flipped the block over, faced it to length and chamfered the OD and ID on the other end as well.

Page 33 of 67

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page