Portable Workbench Build Process

Page 41 of 67

Posted 27th March 2021

Today I acquired...

Some spherical seating washers. I decided to take good advice and just buy these components. Until I can get round to making spherical turning attachment for the lathe, this seemed like the best idea. According to the dimensions on the website I bought them from, the convex parts should have been a reasonable close but loose fit on the bushes I made and the concave ones should have a reasonable amount of clearance for angular adjustment. The latter was true, but the convex ones don't quite fit. I'll have to mount them on the lathe and skim a tenth of a millimetre or so off the bore.

More on that later.

As far as actual work on the bench goes, I started today by drilling out the dog holes for the top.

I then put a chamfer bit in my small router and chamfered all the holes slightly.

There had been a bit of tear out on the bottom of the holes (despite having a backing board: I hadn't clamped the top to the backing board so I think they separated as the drill bit went through). To hide some (but not all) of the tear out (which will never be seen anyway as it's on the underside of the top) I did the chamfer a bit deeper on the bottom.

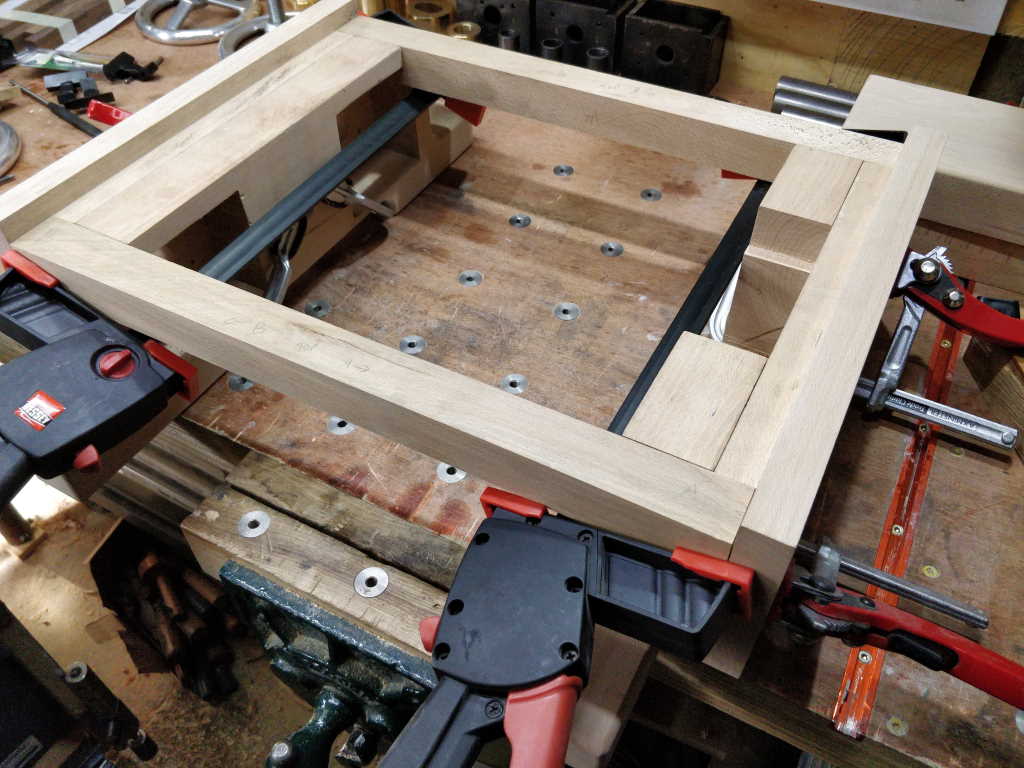

I then put the workbench together with clamps so I could mark out the hole locations:

With the top in place, six of the dog holes are over part of the feet:

I marked the hole locations out by using my 20 mm Forstner bit and pressing down by hand. I then followed that up with an awl to make the mark more obvious.

My plan had been to drill these holes out 22 mm to allow for some movement in the top (which will be attached with buttons). The holes in the foot will be there to allow clearance for longer dogs to be inserted, but they won't be providing precise location or anything, so 22 mm seemed a good size.

Unfortunately, when I came to drill the holes out, I came across a bit of a problem. I was sure I had a 22 mm Forstner bit, but it seems I'm wrong! The outer holes are also only 11 mm from the edge of the wood so that size Forstner bit is probably not ideal. I'm going to ponder on this for a bit. I could just cut the end of that bit of the foot off, but I quite like the fact that the edge of the foot goes up to the rail. I could also cut out more selectively (cut a U-shaped bit out of the edge). To be determined...

Page 41 of 67

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page