Portable Workbench Build Process

Page 26 of 67

Posted 19th March 2021

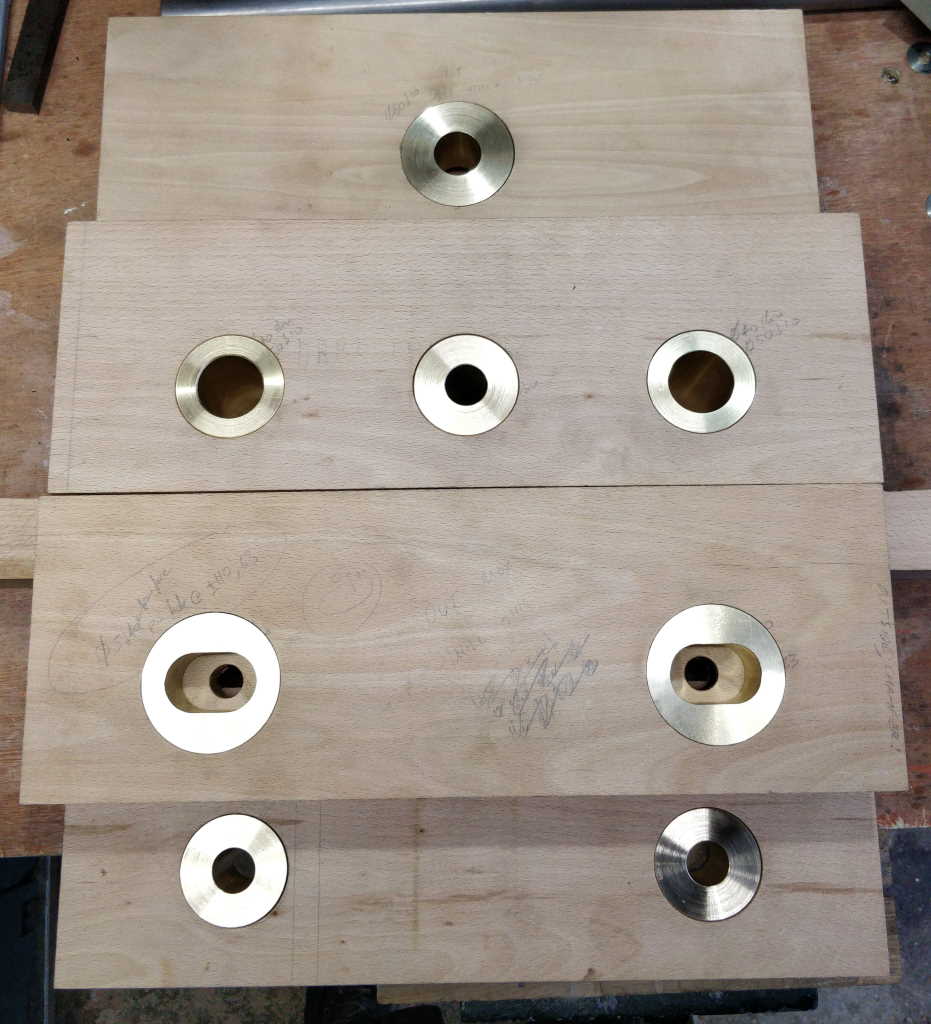

Here are all of the brass parts fitted (but not adhered) into their holes:

This test did highlight some issues unfortunately. For two of the parts (one of the thread bushes for the dual-screw vice and the central bearing for the standard vice), the larger hole in which the flange sits isn't concentric with the central bore. It's not actually that important as it's the central bore that has to be (and is) in the right place to ensure it works properly, it just means that there's a small (0.5 mm maybe?) gap visible on one side of the bush.

This is one of those things that no-one other than me will ever notice (especially once the hand wheel and washer are there), but I'm trying to work out how much it's going to annoy me and whether to do anything about it (and if so, what). The only thought I've had at the moment is to mount the parts back in the mill vice, use a DTI on the inner bore of the brass bush to get the XY table in exactly the right place and then make the hole a bit bigger (somehow - I suspect my boring head would leave an awfully ragged edge). I could then add a contrasting wood (if it's thin and I can figure out how to make it) or aluminium ring around the brass part to make it look deliberate!

I'll ponder on that one; I think it will be a heck of a lot of work…

With all the brass parts made, I did a test assembly of the bench to see what it's looking like.

I also gave the lathe a bit of a clear up and put all the swarf in some freezer bags for saving. I think I've produced more brass swarf in the last two days than I have in the rest of my metalworking life put together.

That lot weighs just over 7.9 kg!

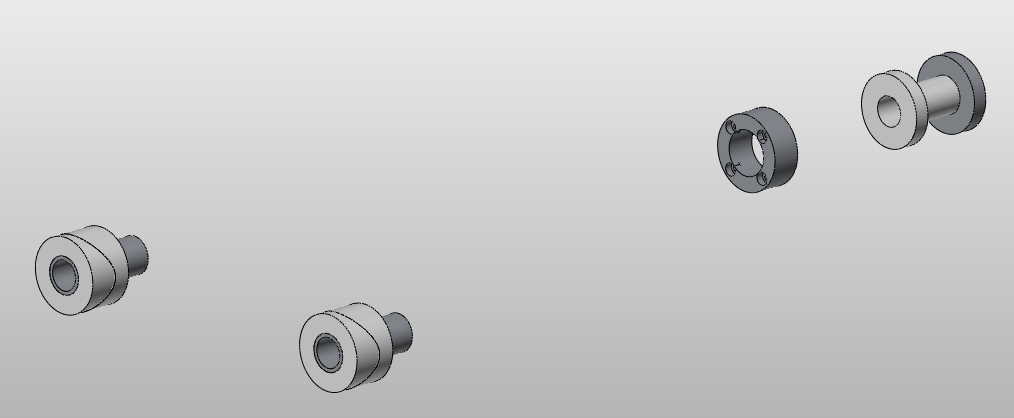

With all the turned brass bits complete, the next job is probably to work on the steel pieces:

Three of these (the darker coloured two tubes on the left and the lighter coloured flanged tube on the right) have threaded holes through, one has some counterbored holes drilled in an awkward location (because this part was an afterthought!), one is a simple washer and four are an attempt at a couple of pseudo-spherical-washers to allow angular clamping. I'll leave those latter parts to last as (if they don't work) they can be replaced with plain washers as I don't expect to do much angular clamping.

Page 26 of 67

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page