Portable Workbench Build Process

Page 27 of 67

Posted 20th March 2021

I woke up this morning firmly of the opinion that the non-concentricity of the hole on the moving jaw of the standard vice was something I can't live with. The one on the fixed jaw of the dual-screw vice I think I can - it's only really visible if you look really closely, unlike the one on the moving jaw which is a much bigger gap and looks (in my opinion) awful.

To that end, I started this morning by getting a big of steel the same size as the inner bore of the brass insert and drilling and tapping it for an M5 screw.

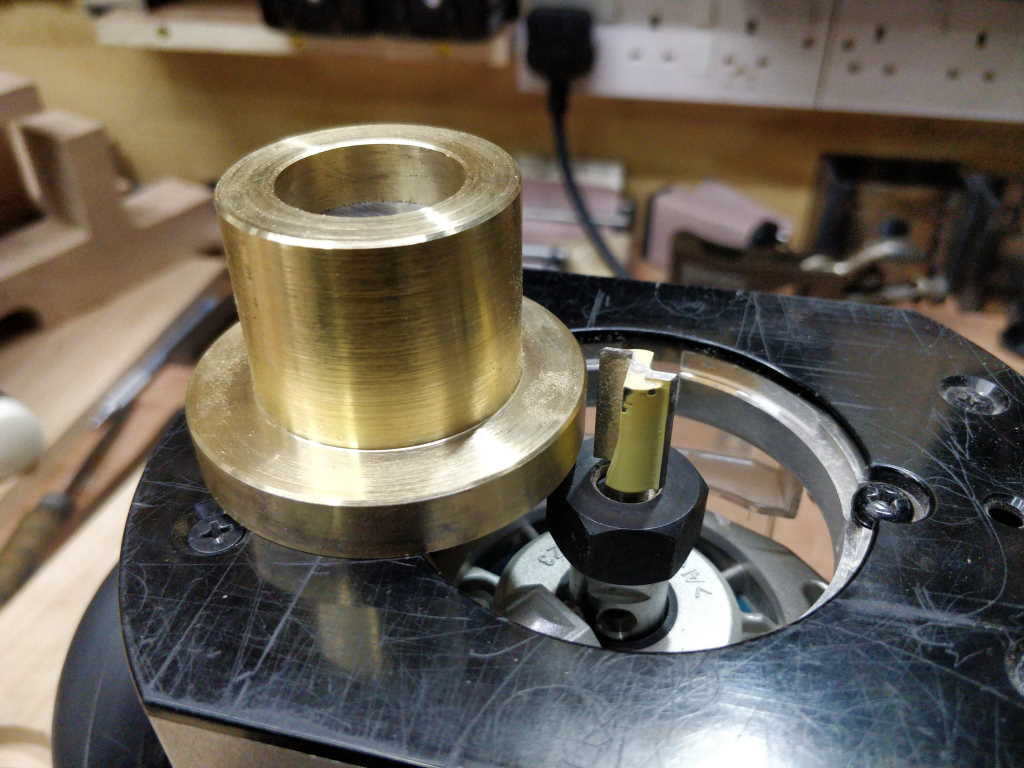

I then fitted an M5 cap screw into one of the threaded holes on my router that is designed for holding guide bushes in place:

I could then screw the block of steel into place.

Sliding the brass "bearing housing" onto the bush allowed me to pick a router bit that wouldn't quite touch the brass.

I could then drop the whole lot onto the moving jaw to rout a circle:

That left a small ridge all the way around the inside of the hole.

Which I took off with a chisel.

Page 27 of 67

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page