Salt & Pepper Mills Build Process

Page 7 of 11

Posted 21st March 2025

Another brief aside from the salt and pepper mills and another entry in the diary of the inept woodturner...

For quite a while (ever since I built my woodturning lathe really), I've been looking for a decent quality and nice looking pencil kit. There is a vast range of pen kits out there, but the selection of pencil kits is a lot more limited, especially if you rule out the gold ones (I prefer the look of a chrome finish). I've tried a few different ones but have never found one I was entirely happy with. When I went to Yandles over the Christmas break I picked up a couple of kits: a so-called "Sienna" kit (which works well, but doesn't look that great) and one called a "Cigar Pencil" kit. I bought a couple of each. I made a Sienna pencil a week or two ago; yesterday I decided to have a go at making the Cigar pencils.

I started by bandsawing up a couple of bits of wood into roughly pencil blank size and then used my 3D-printed pen-drilling jaws to drill the 10 mm hole for the brass insert. The brass inserts got glued in place with araldite and today I decided to turn the two pencils.

The first job was to make some bushes out of 303 stainless steel on the metal lathe (as they're different to any of the ones I've made before). Some pen/pencil kits give the dimensions of the required bushes (hence making it quite easy to make them myself); other kits like this one just tell you an order code to buy a kit, so if you're going to make your own bushes you have to figure it out from the kit. Thankfully it isn't too hard to do so.

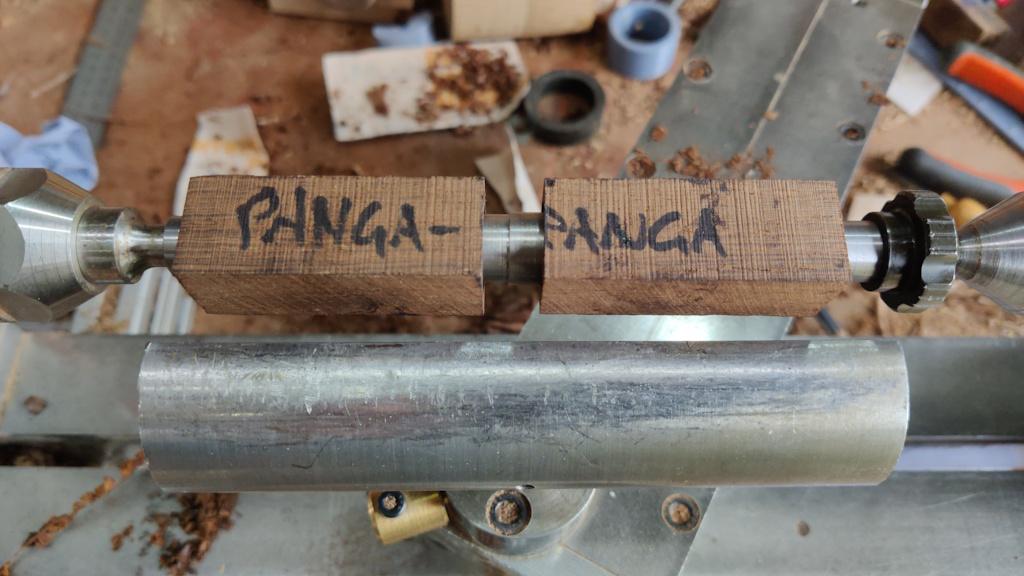

The first pencil was going to made out of Panga Panga:

Believe it or not, by the time I took that photo the inept-woodturner effect had already done its job...

The first thing I did was use a roughing gouge to turn the square-section wood into something a bit more cylindrical:

I feel relatively comfortable using a skew chisel for shaping something like this (as there aren't any corners!), so I used that to shape the Panga Panga:

I then used some sandpaper to clean it up. The finish off the skew chisel was good enough that I felt comfortable starting at 180 grit and then using 240 and 320 grit. The paper in the background of this photo is just there as my phone was refusing to focus without it.

With that, all the turning was done; it probably took less than 10 minutes in total, perhaps even less than 5 minutes. I'm generally not that much of a fan of pen/pencil turning: the amount of turning per kit is tiny. There's a bit of bandsawing to prepare the blank (assuming you don't just buy pen blanks), then a quick bit of drilling, some messy epoxying, a long wait and then a few minutes of shaping.

Anyway, those blanks went in the bin (along with the pencil kit). I assembled the kit, pushing the various bits and bobs into the correspondingly-sized ends of the Panga Panga blanks and then fitting everything together. That's when I realised that, when I put the blanks on the mandrel (as shown in the first photo in this post), I put them the wrong way round, with the shorter one on the left and the longer one on the right, instead of the other way round. There really wasn't much I could do about that, hence chucking it in the bin. It was possible (ish) to get the pressed-in parts out of the brass tube, but they got a little marred in the process and besides, the brass tubes were permanently glued in place so I decided to just admit defeat and chuck the lot.

Thankfully, I'd prepared two blanks (with glued-in brass tubes), so I could at least have another go without having to wait for epoxy to cure overnight. The next blank was Knob Thorn:

Again, it got roughed to a circle:

I didn't quite get the shape right with the skew chisel (it was probably due a sharpen but I was being lazy), but it was close enough for sanding:

Sanding started at 120 grit this time (as the shape was a bit lumpy).

I gave it a coat of hard wax oil while it was still on the lathe:

This is the kit I'm using for this pencil...

... and this is what it looks like when you've turned it correctly (I think!) and assembled it:

It's the nicest looking pencil kit I've made thus far and I'll probably order some more kits and make one or two more. However, it's still not ideal. The pencil "lead" extends by rotating the two halves relative to each other but there's very little friction in that movement so the pencil can over-extend or retract when you're writing with it if the pencil twists slightly in your hand. It also only holds a single lead (it's loaded from the tip rather than filling a tube at the rear).

I'll keep looking for a better kit (and before anyone suggests it, no: I'm not going to try making my own kit on the metal lathe!)

In the meantime, I thought I'd (finally, I hear you all cry) get back to the salt and pepper mills. Some new oak and black walnut spindle blanks had come in the post. This time I decided just to turn them from square-section...

... into round with a roughing gouge:

That worked fine and was quite quick, but not much quicker than the bandsaw method and it made a heck of a mess. I think in future if the blanks are this big I'll use the bandsaw: at least it gives a bit of useful kindling as the waste rather than just a pile of shavings all over the floor.

Stopping there would have been fine, but on two of the blanks (one oak, one walnut), I decided to use the opportunity to get a bit more skew practice (albeit still just cylinder turning, which I find okay with the skew):

With that done, I found myself with a load more cylinders that I can (try to) turn into salt and pepper mills (and a heck of a lot of mess):

Tomorrow we've got the "joy" of trying to buy a car for the other half, so I won't have much workshop time, but if it's not too late when we get back from the south-east then I might start drilling some bores out.

Page 7 of 11

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page