Bandsaw Restoration: New Screws

The way my workshop is set-up, hex (Allen) keys are a lot quicker to grab than spanners - the hex keys sit in a rack on the front of the lathe. I also find it much, much easier to identify (at a quick glance) hex sizes from the limited range that's common compared to hex head, which have a different size depending on where they're from (e.g. M8 heads can be 12 mm, 13 mm or 14 mm AF depending on where they're from: as one of my colleagues used to say: "the wonderful thing about standards is there are so many to choose from!"). Phillips head are just rubbish when compared with the thankfully more common Pozi-Drive, hex-key or Torx. The bandsaw as designed has a lot of hex head screws that need a spanner and a lot of Phillips head screws that are just rubbish.

The effort scale for me goes: tommy-bar, hex-key, pozi-drive, hex-head. As a result of that and the fact that I'm lazy, I very rarely (for example) move the blade guides in and out: I have to remember that this one is a 14 mm spanner, then go and get a 14 mm spanner, then move it. If a a screw has a built-in tommy-bar, I'm much more likely to adjust it properly.

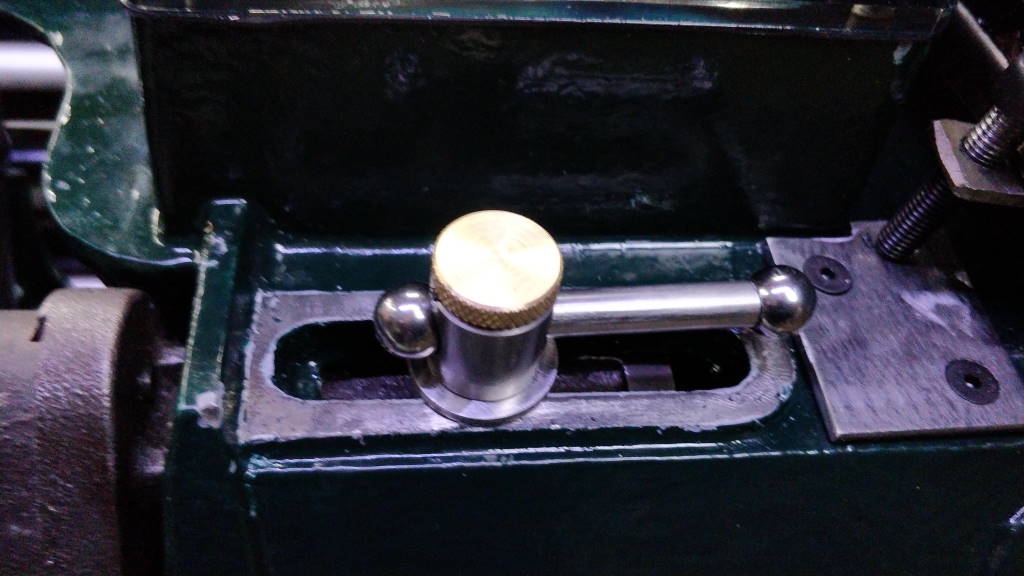

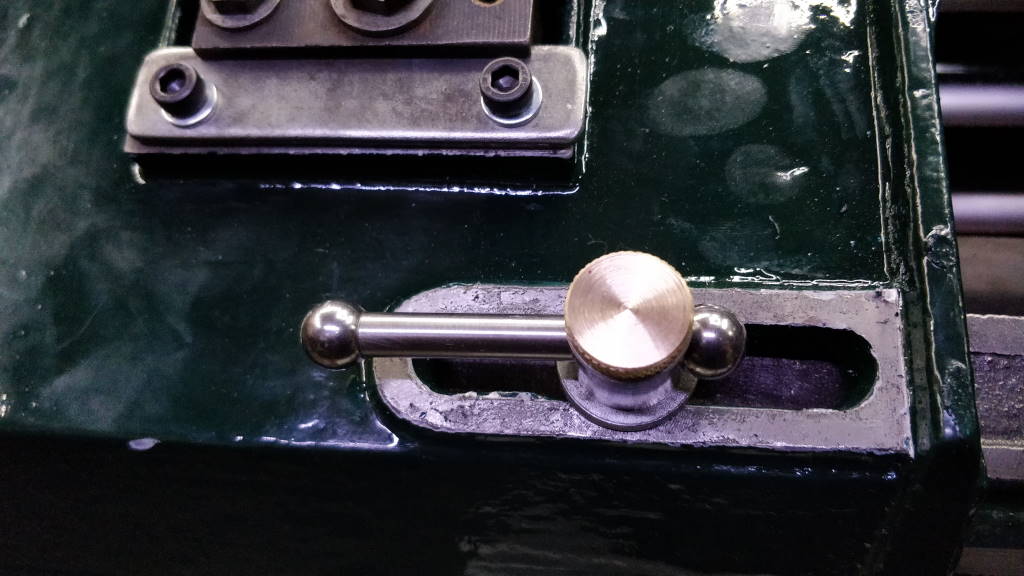

The photo at the top of the page shows the tommy-bar screws that I made for the bandsaw. Each is designed specifically for its location on the saw and the tommy-bar holes have been drilled at an angle that makes them sit in the preferred place when the screw is tight (this was done by fitting them to the saw and tightening them with some mole-grips, marking the preferred angle and then removing them and drilling the holes).

This photo shows the parts that make up the tommy-bar screws. The screws themselves are made from 20 mm diameter EN8, with the thread cut using a single-point tool on the lathe (I could have done this with a die, but I quite enjoy lathe thread cutting).

The tommy-bars are lengths of silver steel. There's no real reason that they need to be silver steel, but I found I'd run out of 8 mm diameter mild steel and had a lot of 8 mm silver steel. The balls are 12 mm diameter and were bought as soft carbon steel balls. I used the lathe to drill 8 mm holes in each one; they get held on the end of the tommy-bars with Loctite 603. After drilling the 8 mm holes in the screws, a 12 mm ball-end end-mill was used to provide a seat for the balls when the tommy-bar is at one extreme of its travel.

This photo shows a close-up of the brass locking screws. These were made from a length of 20 mm brass bar. The outer surface was knurled for a long length and then the screws were made one-by-one by reducing the diameter to 6 mm for a length of 5 mm and then threading (with a die this time). They were then parted off, chamfering with a file part way through the parting process. I kept going until I got to the end of the knurled section, so I ended up with some spare screws.

As can be seen in the photo at the top of the page, the screws go into a tapped hole in the end of the tommy-bar screws and are used to hold the tommy-bar screws in place and to stop them vibrating back and forth while the saw is running.

These photos show the tommy-bar screws for the blade guide brackets after they had been fitted. They are very quick to loosen when the blade guides need to be moved.

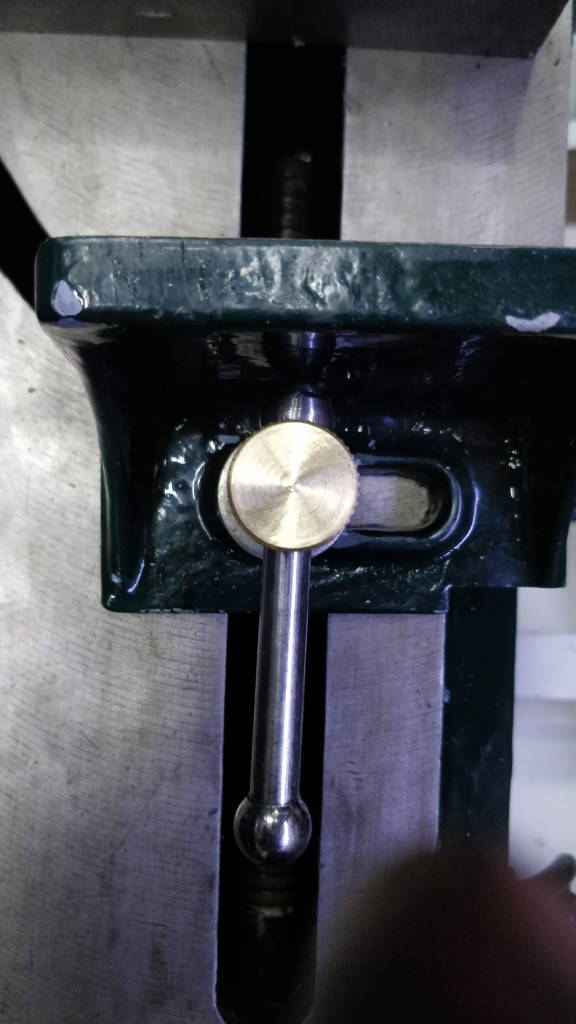

These two photos show the tommy bar screw that holds the moving vice jaw down (along with some of the predicted damage to the paint work that will need touching up later!)

As you can see, the clearance to the jaw is limited and hence this screw has had a particularly deep cut made with the ball-end end-mill. This allows the ball to sit relatively deep within the screw and stops it interfering with the moving jaw when it is tightened.

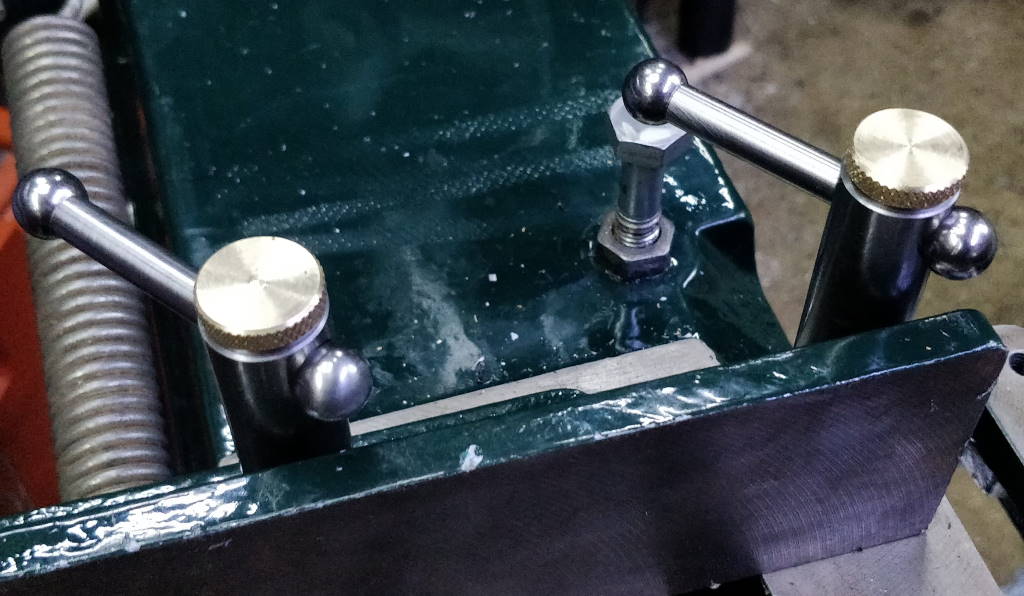

This photo shows the tommy-bar screws for the fixed vice jaw. The angle of the tommy-bars ensure that they don't interfere with any other part of the saw.

This photo shows another view of all of the vice screws.

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.