Mini Moravian Bench Build Process

Page 2 of 38

Posted 21st June 2025

It's been a while since I posted anything on this thread, but with the garden table project drawing to an end and my self-imposed deadline for this project (end of August) looming, I've been spending a bit of time considering the design.

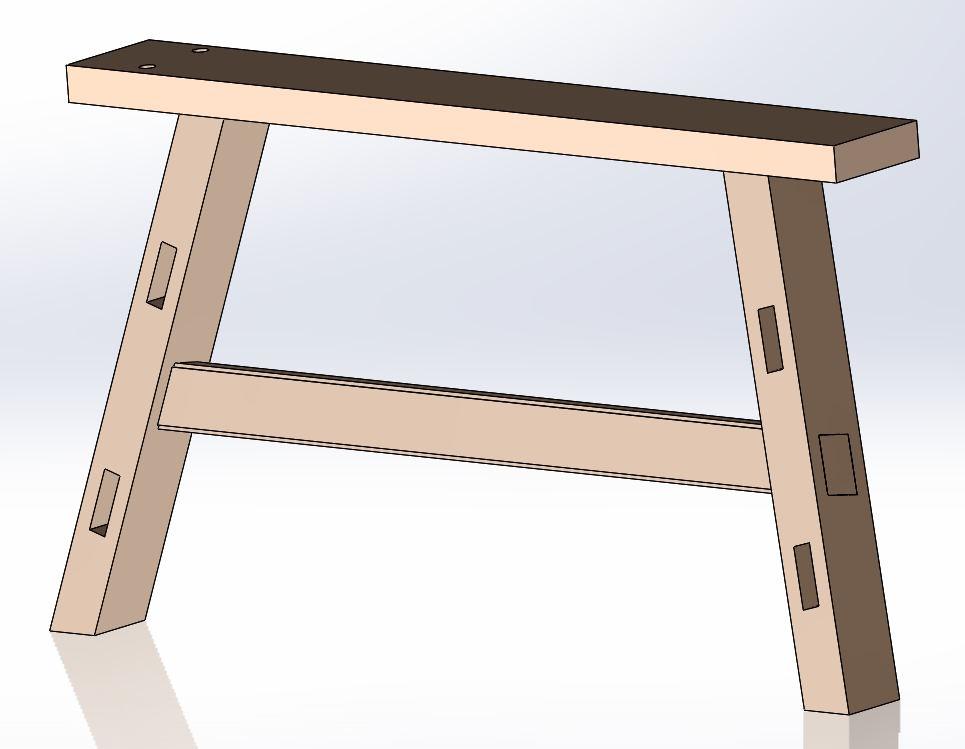

With that in mind, I've made a few decisions (helped a lot by the good folks from the woodhaven forum). Firstly, I'm going to attach the legs to the top with some form of tapered sliding dovetails (aka dovetail housings). I haven't decided which direction the tapered dovetails will go yet though. I've also decided to reduce the size of the components quite a bit and design it around roughly 45 mm thick timber (more on this later). The legs will probably be laminated from two pieces so will be twice as thick.

I've played around a bit with an alternative layout that would have the legs attached to the tops and the long stretchers (so the removed bits are the short stretchers), but I've decided against it now as it would make parts that look (in the CAD model) quite cumbersome and awkward to get into the car.

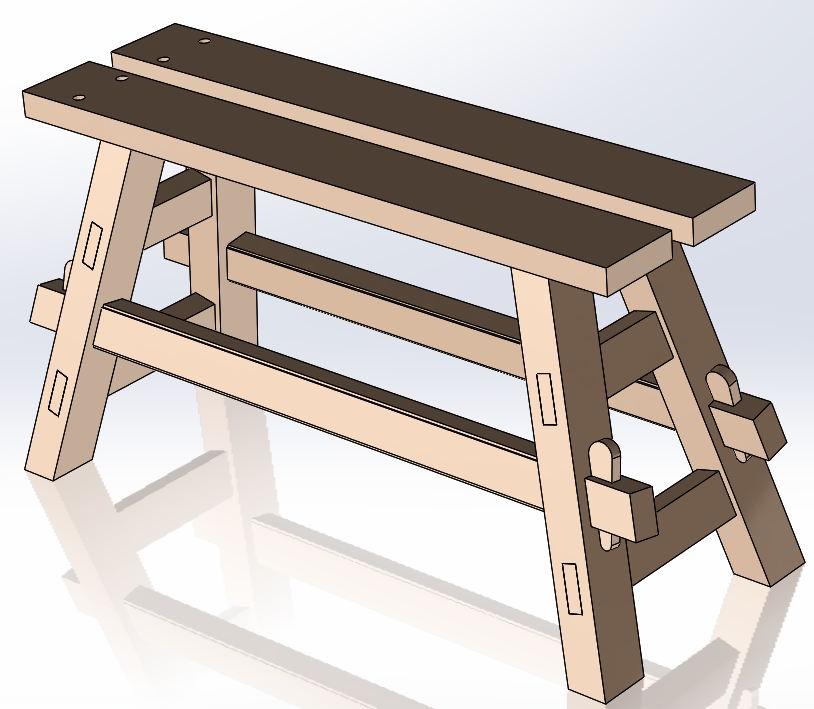

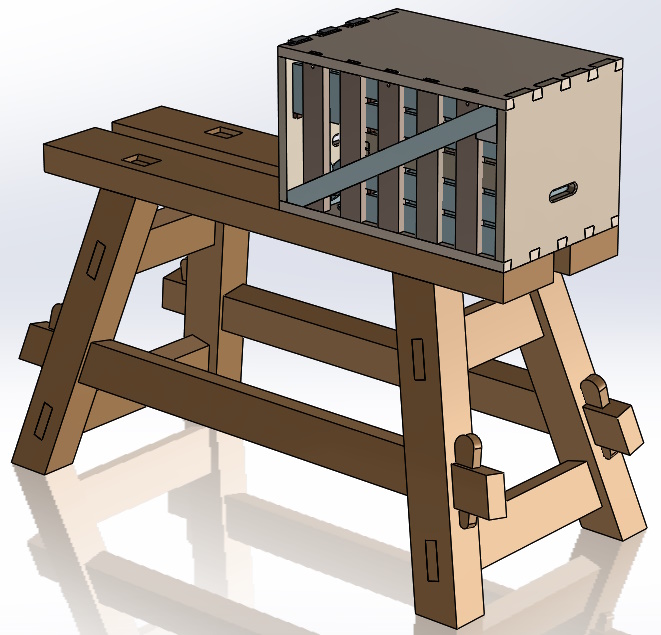

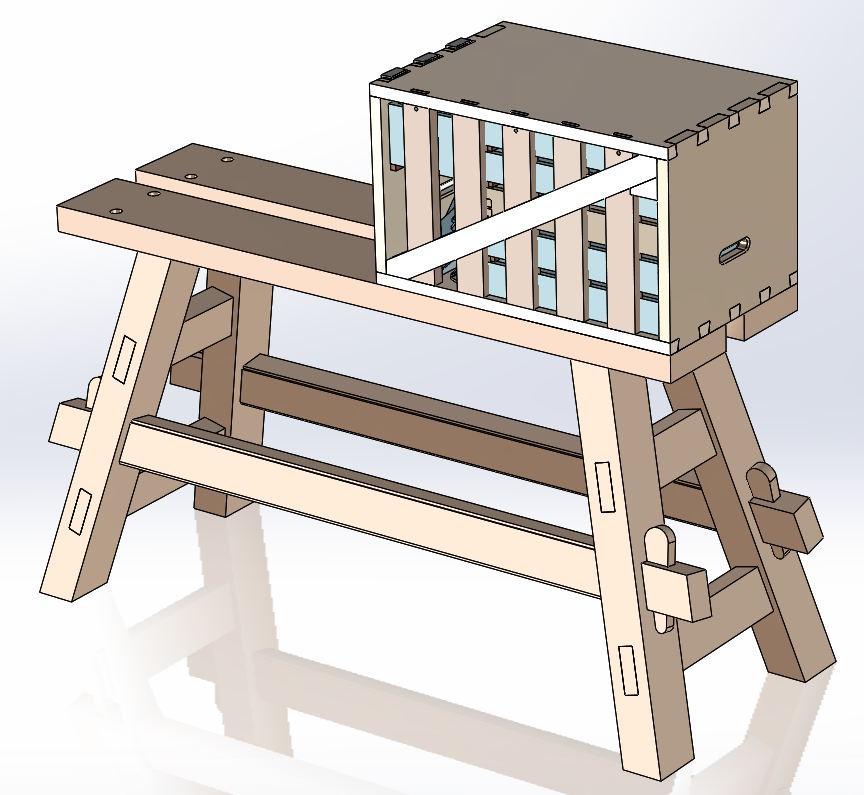

It might not be immediately obvious from the image at the start of this post, but the CAD model at the top of this post is a lot lighter duty than the previous version. Here's a comparison showing old and new versions, both with the chest mounted:

The other decision I've made is the wood to use. As it's a bench and not exactly fine cabinetry, I want to use a species of timber that:

- Isn't too expensive (it would seem a bit daft to make a bench out of English Walnut)

- Is reasonably easy to get hold of (I don't want to have to drive halfway across the country to buy the wood)

- Ideally, is native and locally grown (I really like working with American Black Walnut, but there's a lot to be said for native timbers)

- Is stable and sturdy (I'd like it to be of good "bench calibre" so not something that's going to distort a lot or be too lightweight)

I've got a couple of timber yards relatively close to where I live. One is very close but the prices always seem to be made up on the spot and a lot more than I expect (maybe the owner doesn't like the look of me!). They can also be a bit grumpy when you want to rummage around in their store/kiln (shown in the photo above). The other, Wentwood Timber, is far cheaper, friendlier and in a beautiful part of the country! Their prices seem to me to be a lot lower than most other places that list them explicitly (at least in this part of the country).

The cheapest wood that Wentwood Timber list is Larch (at £22+VAT per cubic foot). I've never seen any larch when I've been to Wentwood Timber and it doesn't seem very appropriate for what I want anyway, so that was easy to rule out (but it did give me an excuse to include a Monty Python clip in this post!). The next tier (at £25+VAT per cubic foot) includes Alder, Ash, Beech, Lime, Poplar and Sycamore. Cherry, Sweet Chestnut and Cedar of Lebanon are not far behind at £30+VAT per cubic foot.

A few of these I ruled out quite quickly, in particular Alder, Cedar of Lebanon, Lime and Poplar as I wanted something a bit more hardy. Sweet Chestnut is a candidate, but with the garden table and travel toolchest, I've been using a lot of that lately and it would be nice to work with something else. Ash is low on the list as the stuff I used to make the shelf unit recently was a pig to plane (lots of grain direction changes). Cherry is rarely available at Wentwood so that one is probably out too.

All of that contemplation left Beech and Sycamore with Sweet Chestnut as the fall-back option. I rang Wentwood Timber and asked what they had in 50 mm (2") boards with a reasonably straight grain. They had no Beech at all, but had plenty of Sweet Chestnut and Sycamore.

The old Wentwood Timber website (still available on archive.org) had a page describing the woods that they stock. This is what they had to say about Sycamore:

Sycamore is sometimes known as the home-grown Maple. It is closely related to Maple and has similar grain and qualities, albeit slightly less dramatic grain. It has a long history of use however for kitchen utensils as it will not impart any taste or smell to food. It also looks very nice as kitchen cupboards or furniture where it is similar to Birch, but perhaps rather more attractive. Sycamore is very very stable, and is the only native timber where you are likely to be able to get a really wide board and have little or no cupping or splitting. This makes it especially suitable for furniture. Some boards will be very clean and have no markings other than the subtle growth rings (which are very pretty) and other boards will have a host of colours ranging from slight marbling through to serious spalting. Ideally when selecting boards make sure at least one face is planed so you know what you are getting.

The fact it's stable sounds ideal to me so I think we have a winner. Off to Wentwood Timber we went yesterday and I had a rummage around in their hardwood showroom, but all the thick boards of Sycamore were looking very rippled (I'm ideally after something with a straight grain to make my life easy). There was plenty of thick Sweet Chestnut that would do the trick but I was still hoping to use something different. I wandered up to the office and asked if they had any more. Coincidentally I found myself talking to the guy I'd spoken to on the phone and he led me back to their drying area, where they had plenty more Sycamore that was dry and ready but hadn't been moved to the showroom yet. We had a good rummage and pulled out these two 50 mm thick planks (which set me back about £100):

All being well, that'll be enough timber for the bench, but it's not the end of the world if I have to go back to Wentwood to get some more. I've turned a couple of bowls out of Sycamore before (using my home-made lathe) but I've never tried other types of woodwork with it, so it should be interesting to see what it's like.

My plan with the timber is to turn it into planed-all-round (or at least planed and thicknessed) boards of about 150–160 mm width. Some of those will end up getting cut in half to be 70–80 mm width, some will stay full width. When I've worked out what I've got (how thick they end up, how wide and long they end up), I'll tweak the design to suit the wood available. I'm expecting something of the order of 45 mm thick, but I'll make the design match whatever thickness I achieve.

That feels like a good way to go about it for this project. There isn't a fixed size requirement and neither is there a fixed requirement for board thickness. Tweaking the design to suit the material I've got seems much better than trying desperately to get hold of wood in a size that the CAD model says is "right".

I'm probably going to use a bit of powered assistance for this first step. Part of the reason for that is that it's flipping hot at the moment and the idea of hand planing a bench's worth of Sycamore doesn't fill me with glee. The other part of the reason is that I have imposed a fairly tight deadline on myself and I'd rather give myself plenty of time for joinery rather than using it all up on hand planing. I don't have a surface planer, but I can roughly scrub plane one side of each piece to get it to be flat-ish and twist-free and then use the thicknesser to do the rest of the hard work (starting with the scrubbed side down and then flipping over once the second side is planed). I'll still use a smoothing plane to finish it off as I definitely don't want to be doing any sanding on this project.

Page 2 of 38

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page