Bandsaw Restoration: Base Frame

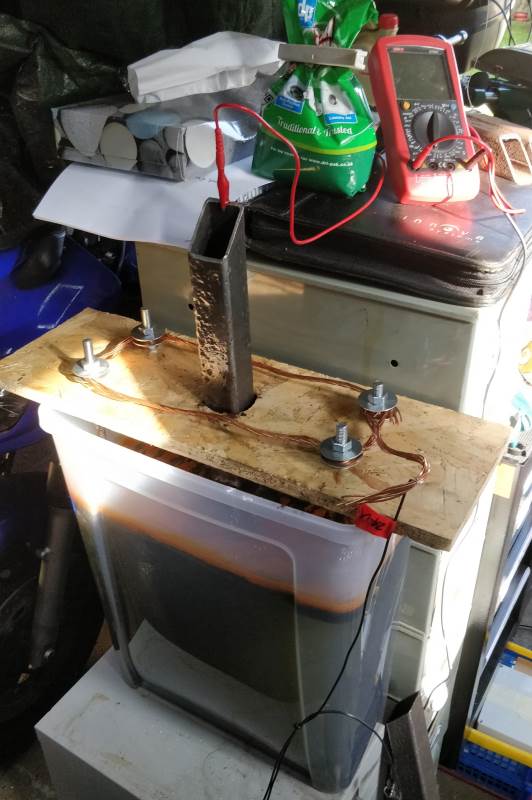

I recently inherited a couple of long (5 m maybe?) lengths of extremely rusty box section steel from my father-in-law. These are 40 mm × 40 mm × 3 mm, but had been sitting in his garden for 20–30 years so had a very thick layer of rust on them. It seemed a shame to just send them to the tip, so I decided to have a go at derusting them and make a new base for the bandsaw. The photo above shows one of the bars halfway through derusting (I couldn't fit the whole thing in my derusting tank): hopefully it gives an idea of quite how thick the rust was on this box section steel.

I derusted using the electrolysis method. I used a plastic bucket filled with water as a derusting tank. A piece of OSB wood formed a loose lid and held four bits of M10 threaded bar to act as sacrificial electrodes. They were connected together with some (ridiculously thick) copper wire and then connected to the positive terminal of a 24 V power supply. The 0 V terminal was connected to the box section via the current-measurement terminals of a multimeter. I inserted the box section and gradually added washing soda crystals (from the green bag you can see in the photo) until the current measured by the multimeter was about 4–5 A. I then left it alone for a few hours. The box section came out of the tank completely black, but a quick brush with a wire wheel on the angle grinder made it look like steel again!

Once all the box section was free of rust (on the outside at least), I built a new base for the bandsaw (all TIG welded).

The angle brackets on the top are for mounting the bandsaw; the strange thin plate is to stop swarf from the area directly under the blade from falling into the area that will eventually have a couple of shelves. The eight holes (which are threaded M10) in the four bottom pieces were used with some threaded bar to make a temporary frame that helped me fit the upper and lower rectangular frames to the uprights (which aren't at right angles in either plane) - this was one of the most difficult welding jobs I've done so far (and another one was welding that thin plate at the top onto the much thicker box section).

As you can see in the photo, I decided to make the frame with four castors. The original frame had two castors (missing before I bought the bandsaw) and the other end just rested on the floor. I have a very limited amount of floor space in the workshop. Having four locking castors should make it a lot easier to move the bandsaw into different spaces to get it out of the way of whatever I'm working on.

This photo shows how the bottom casting of the bandsaw fits onto the new base.

I added a side panel cut from 0.8 mm mild steel, again to keep the swarf off the shelves.

These photos show how the shelves will fit. The middle shelf supports (shown in the left-hand photo) are made mostly from 3 mm × 25 mm flat bar. In the corners are some plates cut from 3 mm sheet. You can also see that I added a middle support onto both the bottom frame and the middle shelf support: the shelves are made in two pieces to allow them to be fitted inside the frame and hence the extra support is beneficial.

The bottom two shelves will be used for storage; the top shelf is simply there to stop swarf from falling down onto the shelves.

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.