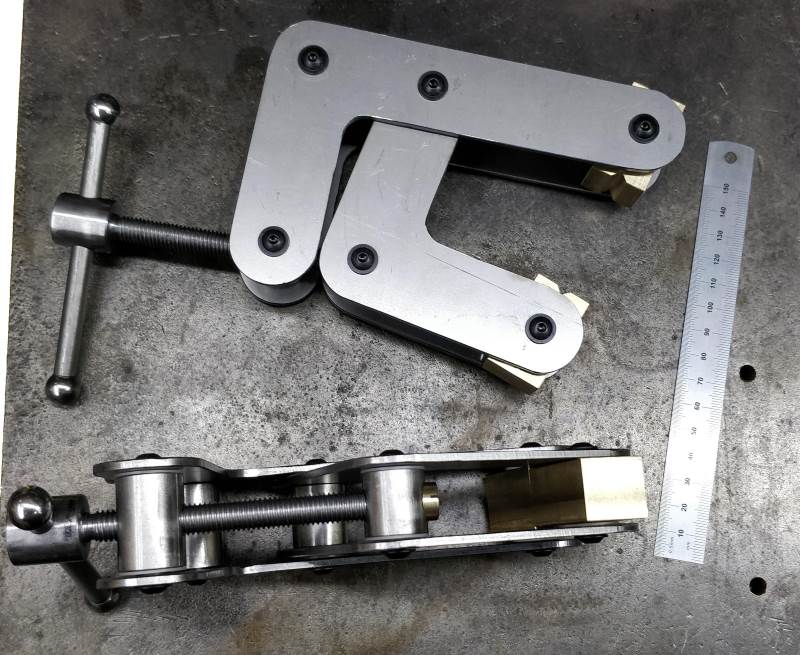

Cantilever Clamps

These are a couple of cantilever clamps I made for general work holding. The arms are made out of 3 mm mild steel sheet, the jaws are brass, there are some acetal washers and everything else is made out of EN1A round bar.

This photo shows the arms, along with a collection of T-nuts I made for the rotary table that I used to machine the rounded ends. The long T-nut bridges the central hole in the rotary table, allowing me to clamp the hole nearest to the end being rounded. The plates (of each different size) were clamped together and the corners rounded all at the same time.

This photo shows the finished jaws, the two sizes of acetal washers and the un-machined bar stock for the joining pieces (I didn't take any pre-assembly photos of the finished joining pieces). The joining pieces are all either 20 mm or 15 mm diameter EN1A; the wider jaws are 22 mm × 22 mm × 38 mm; the narrower ones are 20 mm × 22 mm × 38 mm. All of the joining pieces are held in place with ISO 7380 F M5 flange button head screws.

The clamping screw (visible in the top photo) is made from a piece of 20 mm diameter EN1A. It is threaded M10 for most of its length and has an M5 hole in the end. A home-made brass shoulder screw holes this into the (unthreaded) joining piece in the moving arm. The joining piece in the fixed arm is threaded M10 and provides the clamping force. The tommy bar is made from a piece of 8 mm steel bar. The ends are 12 mm unhardened balls that have been drilled with 8 mm holes; they're held in place with Loctite 603.

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.