Restoring an Old Bench Vice

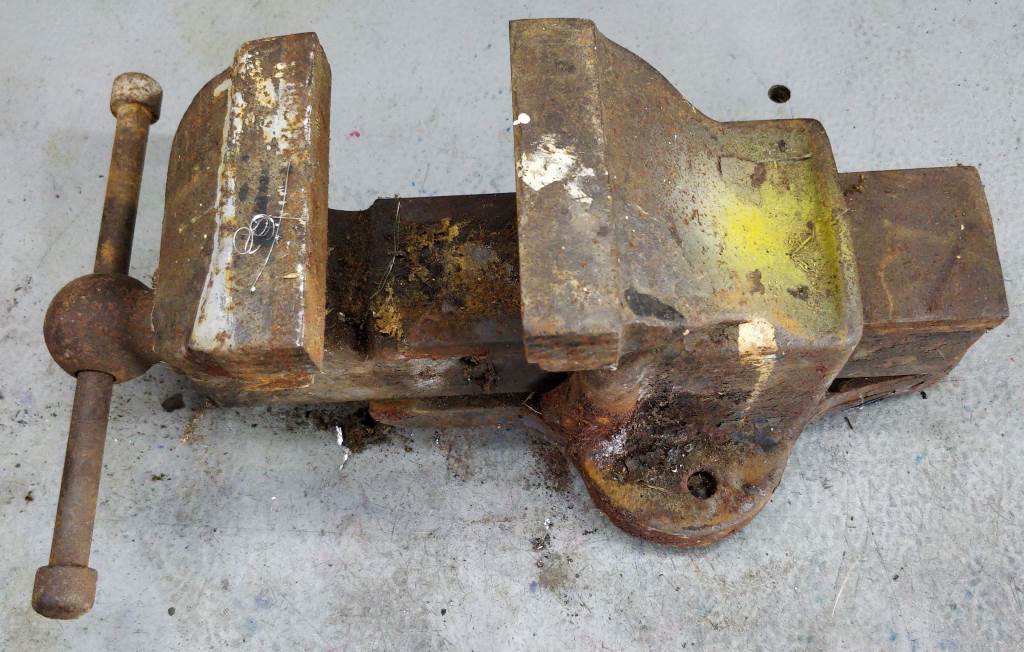

I recently inherited an old bench vice from my father-in-law. As you can see from the photo on the left, it had been in a damp shed for a lot of years and was looking rather sorry for itself.

This shows the parts of the vice after I'd started to take it apart. The vice jaws are still attached in this photo. I suspect the jaws have never been removed since the vice was new and the screws were very firmly attached. One came out with the aid of a manual impact screwdriver, two came out with drilling and a screw extractor, the last one broke the screw extractor and I ended up having to weld a bit of bar stock to it in order to get it out.

With the jaws off and a superficial clean, there was still a lot of rust on the body parts and the handle, but the thread and the spring was looking okay. I was about to go on holiday for a couple of weeks, so I got an old toolbox and filled it up with white vinegar. All the vice parts (except the spring, washer and cross-pin) went in the vinegar bath, along with a plastic carrier bag full of bricks to use up some of the extra space and reduce the amount of vinegar required.

When I got back from holiday, this is what the toolbox looked like!

The parts came out of the toolbox and were given a quick rub-down with a wire brush. In this photo there are still a few bits of rust where it was difficult to get a wire brush to: these were addressed after taking the photo with a Dremel with a small diameter wire brush in the spindle.

The vice jaw screws were by now in a lot of pieces. The vice is old and the threads for the jaw mounts were from some outdated thread standard, either 1/4" BSW or 1/4" UNC. Rather than bother trying to get hold of the old-fashioned screw, I decided to drill the thread out and insert an M6 thread repair coil. This shows a simple alignment tool I used to ensure I was drilling square (it's just a cylinder of steel with the right hole size drilled through). This was held in place with a clamp and a battery powered hand drill used to remove the old thread.

Here is the vice jaw mount with its metric thread coils inserted.

It was then just a case of painting all the bits that needed painting. I used Hammerite as I already had some: this was painted directly onto the bare metal. Time will tell whether I should have used a primer, but it's holding up well so far.

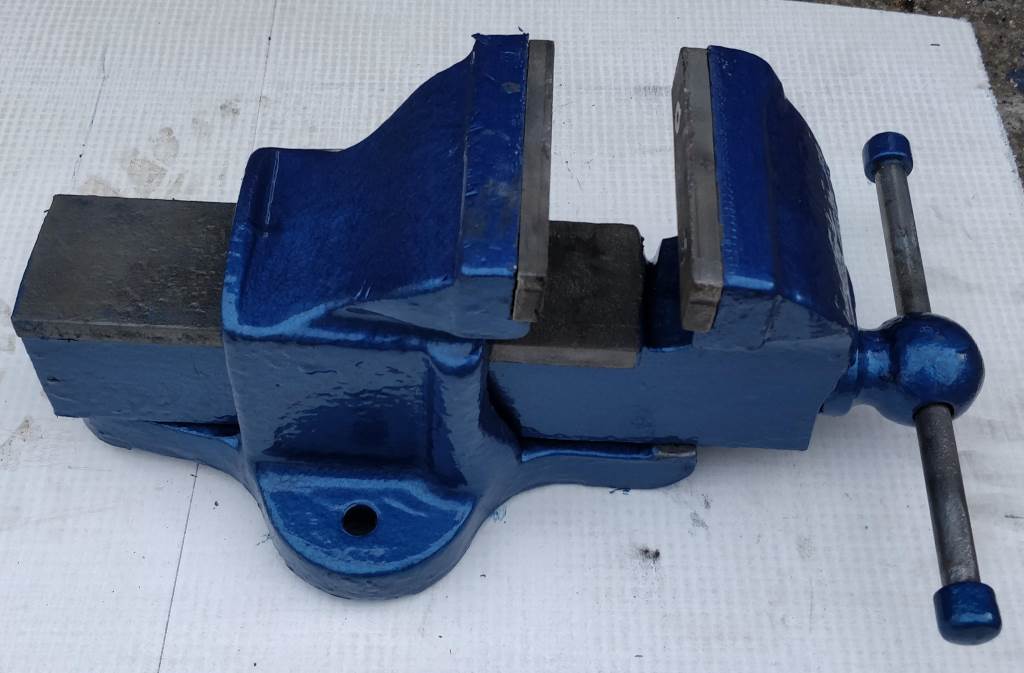

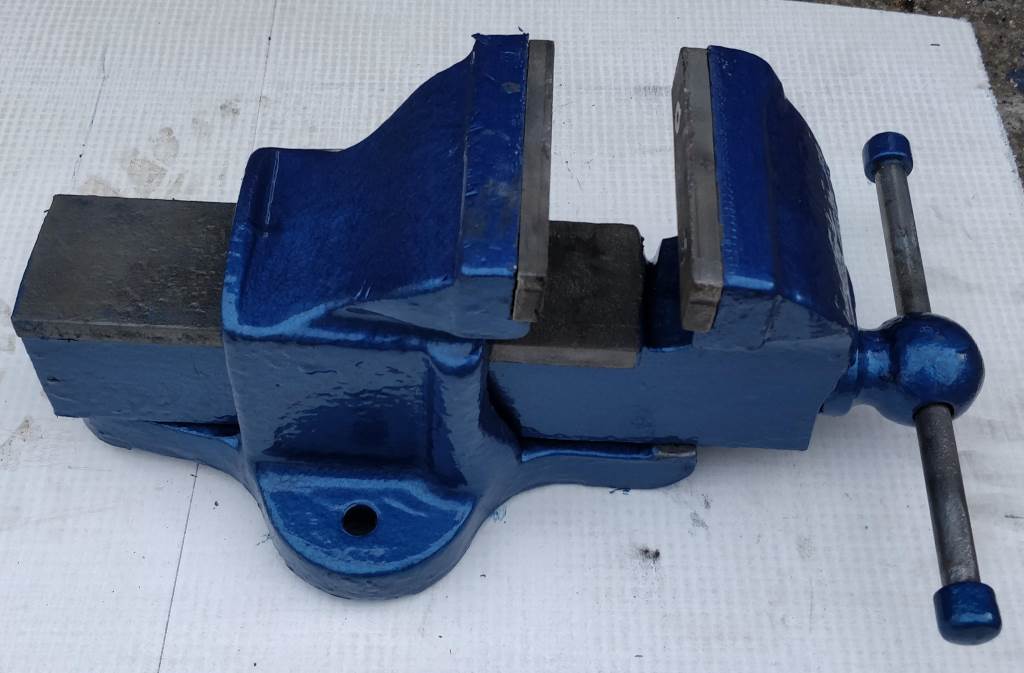

The finished article, ready for use; now I just need a bigger workshop so I have space to mount it somewhere!

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.