Holders for Small Tools

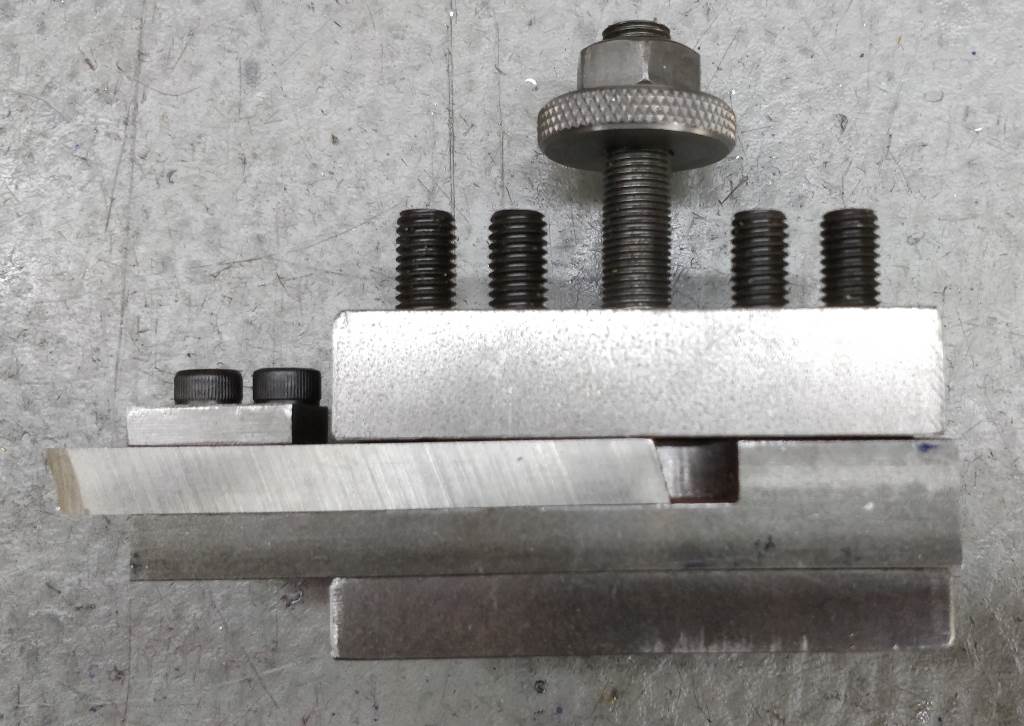

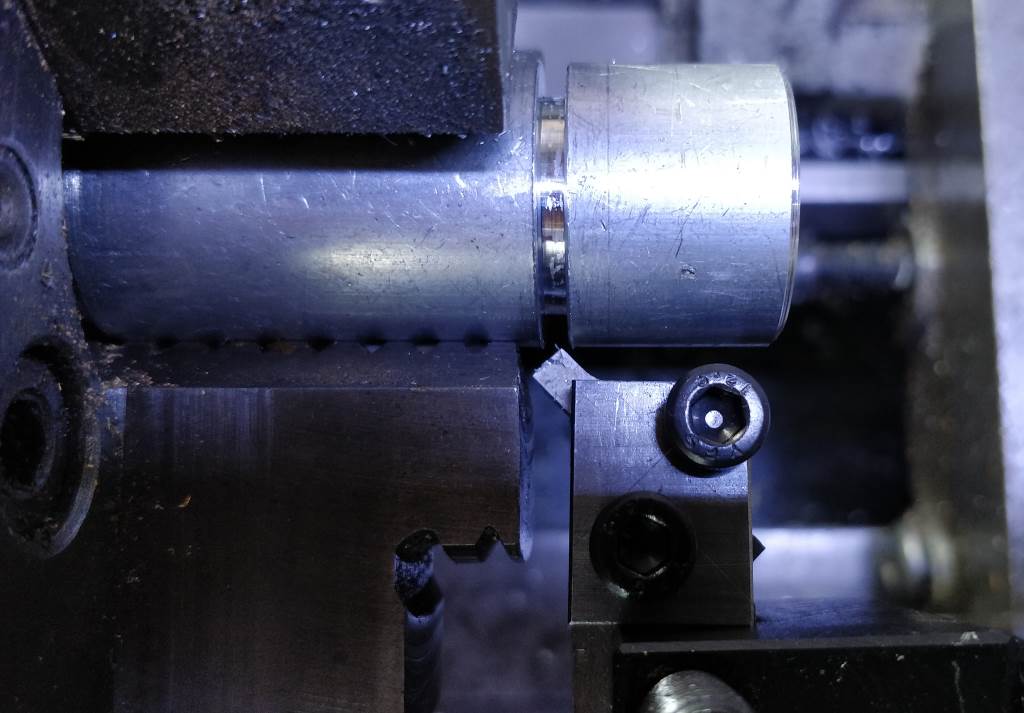

These are a set of very simple tool holders that I use to hold 8 mm HSS tools in my BXA tool post tool holders. Holding the tool directly in the tool holder limits how far that the tool can protrude from the holder without chattering and this in turn limits turning somewhat as the tool post can interfere with the tailstock. By using a larger cross-section body most of the way to the tip of the tool, deflection is reduced for a given force (by about 8 times), hence improving the cutting action. This means I can use 8 mm (or 5/16") tools in most of the same applications that I would otherwise use 16 mm (or 5/8") tools: the smaller tools are cheaper and much quicker to grind. The tool on the right-hand side of the left-hand photo is a parting-blade style holder for a small piece of old hacksaw blade. This can be used for cutting small grooves (e.g. for circlips).

Construction is very simple. They were made from 16 mm mild steel square bar (some are EN1A, some are EN3B as I had two different bars lying around). An 8 mm wide slot is cut to a depth of 7.8 mm along a 70 mm length of the body. A 4 mm × 16 mm × 16 mm clamp sits above the tool and is held in place by two M5 cap screws. The rear end of the 8 mm tool is held in place by the clamp screws of the tool holder.

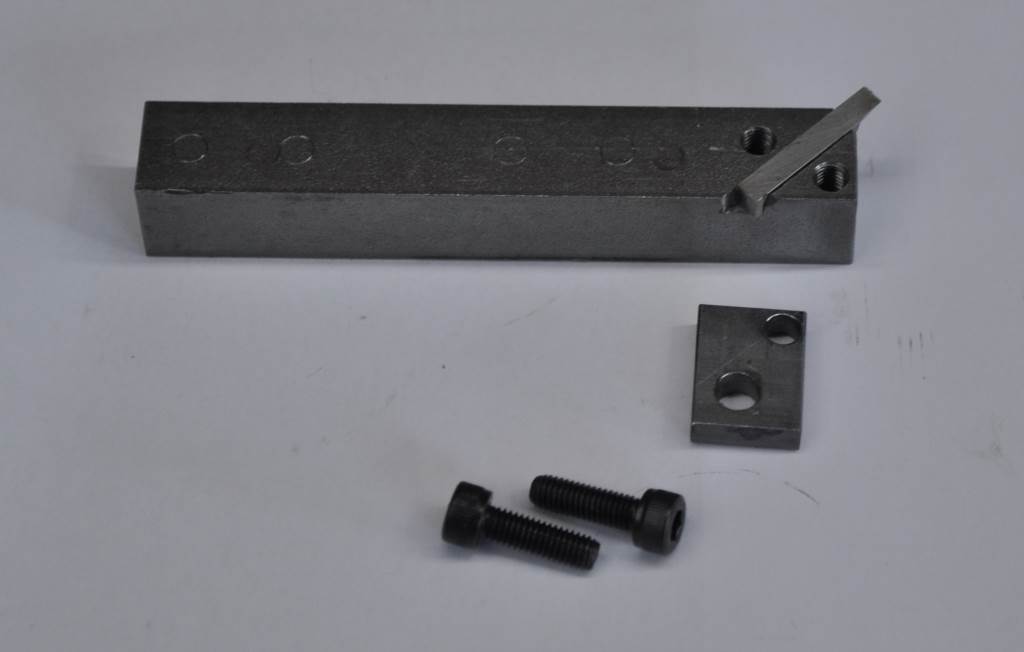

This is another simple tool made on a similar principle (click the photos for a clearer view). The slot is cut at 45° and holds a 4 mm square tool bit. It is used for chamfering and has proven invaluable for chamfering the left-hand edge of a part after starting a parting cut near the chuck. Assuming a 2 mm wide parting blade, there only needs to be 1 mm clearance (actual minimum is 0.83 mm) between the parting tool and the chuck to allow access for chamfering.

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.