M250 Back Stop

This is a simple back stop for making it easy to place parts in a chuck at a consistent depth. It is modelled on the same principle as the one I made for the mini-lathe; the main difference is the thread being integrated into the expanding piece, allowing the use of a smooth 12 mm bar as the stop, rather than some threaded rod.

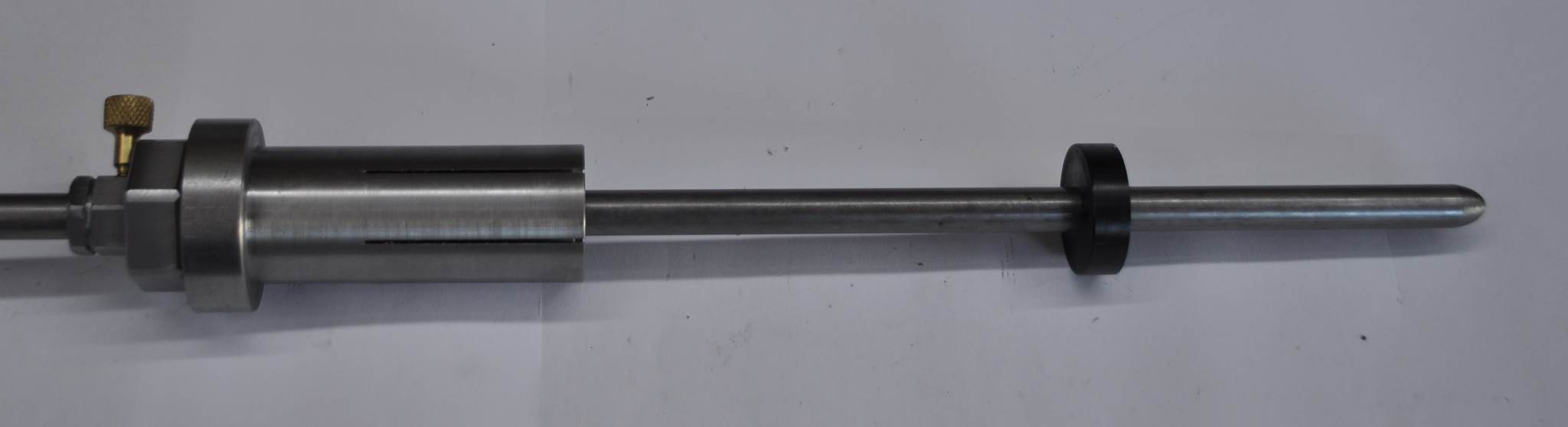

This photo shows all the parts that make up the back stop (like all photos on this website, you can click on the photo for a bigger view).

The backstop bar is a piece of 12 mm EN1A bar. One end has been shaped to form a dome (manually using a hand file while the bar was turning in a collet chuck). The other end has been reduced in diameter to 10 mm and threaded M10. This is intended to be used where a custom shape end is needed (either a small diameter point or a large diameter to contact the back face of a part with a large bore). There is also a nylon disc, about 35 mm diameter and about 10 mm thick with a 12 mm bore that is a tight sliding fit on the backstop bar. This is arguably superfluous, but just ensures that the end of the bar nearest the chuck doesn't wander around in the large spindle bore.

This photo shows a close-up of the main parts of the backstop. The outer piece (body) is 50 mm diameter for 15 mm thickness and then 35.6 mm for the remainder of the 100 mm overall length. The six slots are 1.6 mm wide and about 55 mm long. The inside bore is 25 mm for 45 mm length (from the thicker end) and then 30 mm for the next 45 mm. The remainder of the length is tapered with a 20° included angle.

The inner part (expander) is 25 mm for most of its length, tapering out to 33.6 mm in the last 25 mm. The other end has a 20 mm section threaded M24×1.5 and a 19 mm section machined into a 19 mm across-flats hexagon. A circlip groove was added in case in future I want to hold some custom gears on the hexagon portion for something like my mini-lathe dividing attachment. An M4 tapped hole was added for a brass clamp screw to hold the backstop bar in place. The expander has a 12 mm diameter hole all the way through for the backstop bar.

The nut was made from 40 mm diameter round EN1A bar. It is 10 mm thick and has been milled down to be a 36 mm AF hexagon. It is threaded internally M24×1.5.

I have fully dimensioned drawings for the backstop; please get in touch if you're interested.

A 3D Model

If you have a relatively modern browser, you should be able to drag the model below around with your mouse to look at it from different angles. The left mouse button will rotate the part, the right mouse button moves it and the scroll wheel zooms in and out. On mobile phone browsers, one finger rotates the model while two can be used to pan and zoom. Note that the model may take a few seconds to load.

The checkboxes underneath the model allow you to make individual parts visible and invisible as necessary.

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.