Ball Turning Attachment

This is a ball turning attachment I made for my lathe. It's based on a boring bar that I already had: I've already got an R8 and an MT3 arbor for it (the R8 one is used for boring in the mill; the MT3 one is used with a dead centre inserted as an adjustable offset tailstock centre for taper turning). I decided it would be fairly straightforward to make an adaptor that would allow it to be used in the toolpost for ball turning.

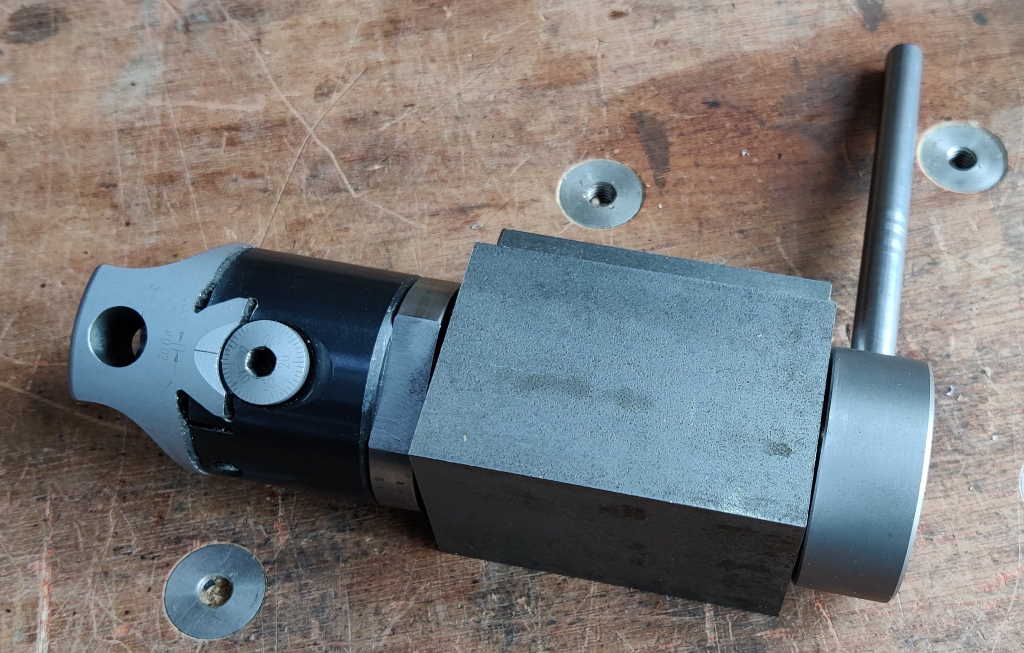

The photo above shows all the parts that make up the ball turner (as well as the off-the-shelf R8 arbor). A lot of the dimensions were chosen based on what material I had lying around.

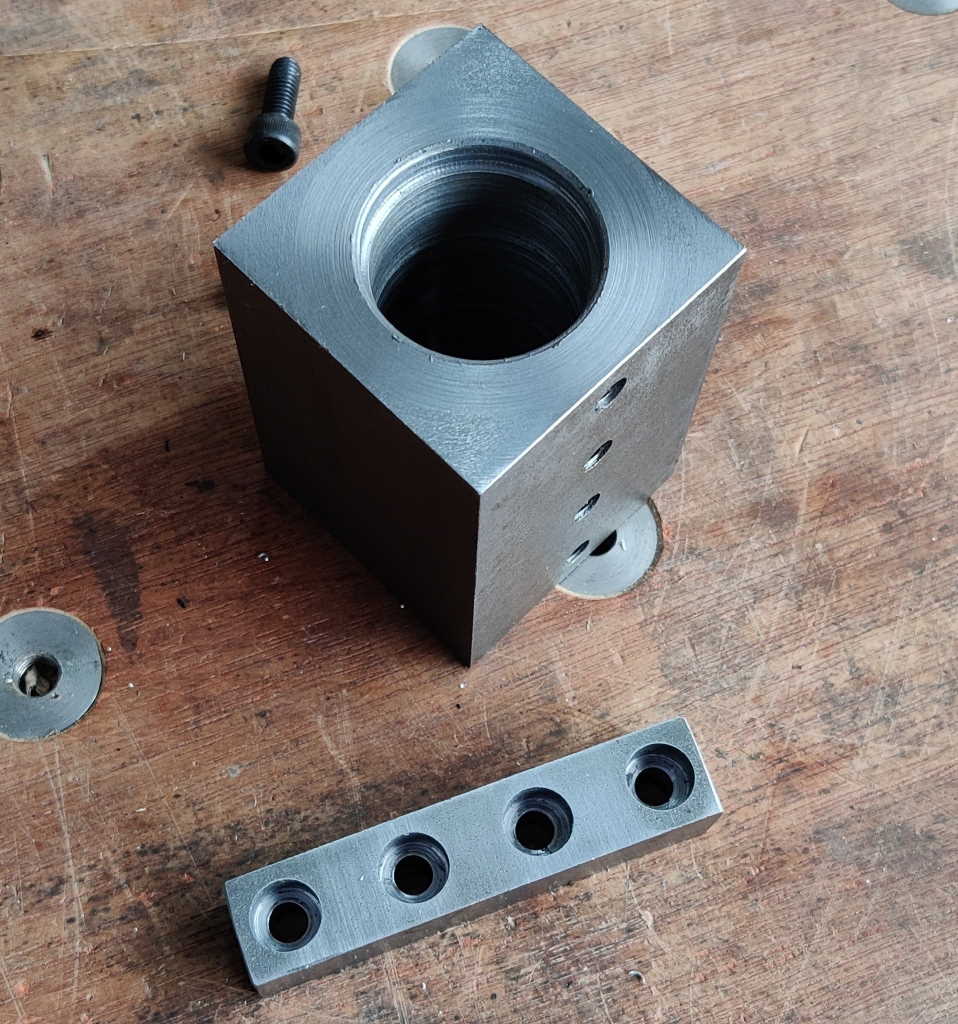

This photo shows the body and the bar that goes in the tool holder. The body is made from 50 mm square EN1A and the bar from 16 mm square EN1A. The two parts are held together with some M6 cap screws.

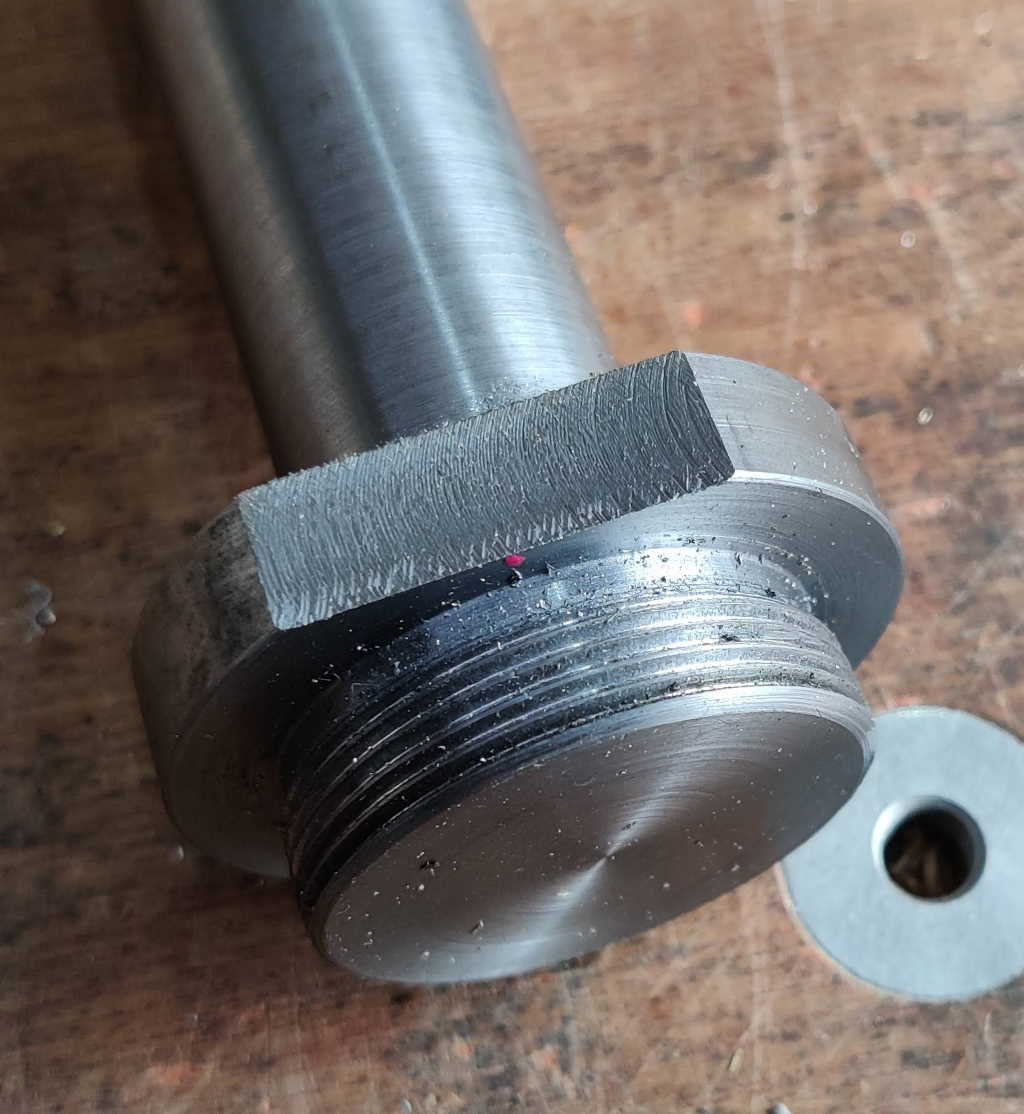

These photos show the shaft. It was made from 50 mm diameter EN1A with most of the length turned down to 25 mm to be a close sliding fit in the bush. The rear of the shaft has four dowel pins glued into place and a central M6 tapped hole.

This photo shows the bush, made from a piece of 32 mm diameter brass bar. It is glued into the body and provides a better running surface for the shaft to turn in. The photo also shows the handle, which was made from a bit of 10 mm EN1A bar and is threaded to fit into the rear block. After taking all the photos on this page, I used the ball turner to round the end of the handle off (with a long cap screw temporarily used in place of the handle).

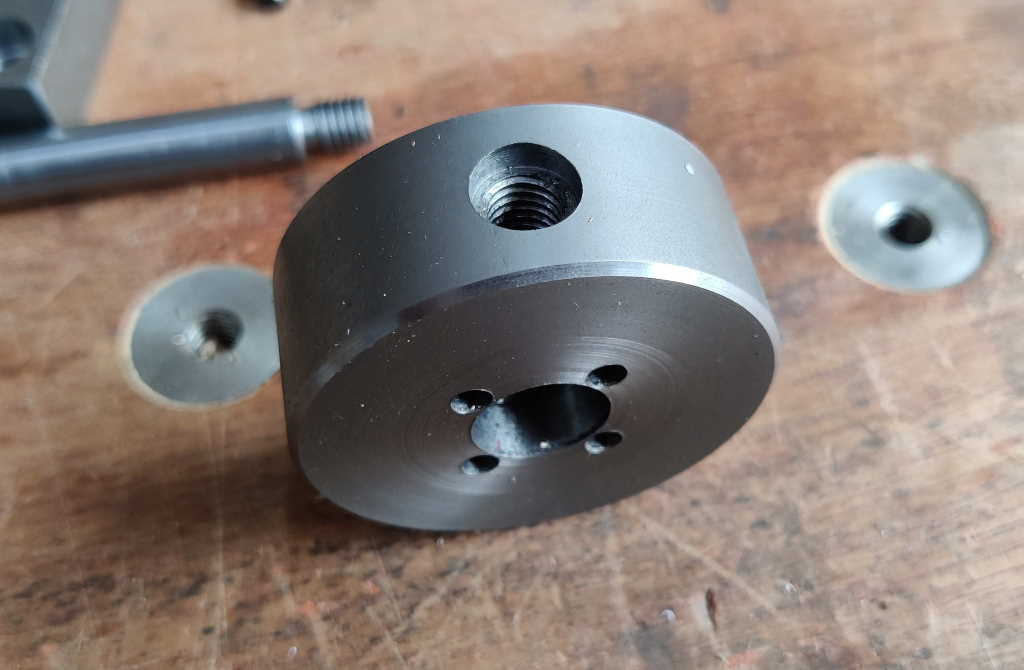

This shows the rear handle block, again made from 50 mm diameter EN1A. It has four holes that slip over the dowels on the back of the shaft and a counterbored hole for an M6 cap screw to hold it onto the back of the shaft and thus retain the shaft in the body. The threaded hole shown at the top of the photo is for the handle.

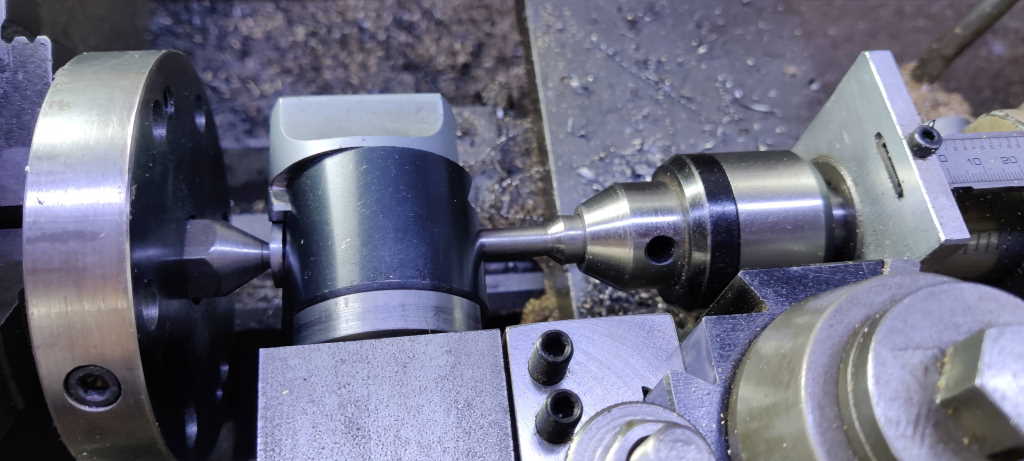

These photos show the method I used to initially set the height of the ball turner using the tool holder's M10×1 mm height adjuster screw. The two centres (headstock and tailstock) held the tool holder in roughly the right place.

This shows the very first test of the ball turner. The ball wasn't perfectly spherical and I had to slightly tweak the height of the tool holder in the tool post, but I was still pleased with it for a first attempt.

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.