Mill DTI Mount

I often use a dial test indicator (DTI) or dial gauge to align workpieces on the milling machine. With a digital read-out, this can even be done when you want the workpiece or vice to be set at an accurate angle relative to the travel of the table. There's a great video here on a really quick and easy way to adjust the alignment of a machine vice.

For aligning the spindle with a hole, the ideal place to mount a DTI is to the outside of the spindle. I haven't implemented a way of doing this, partly due to the size of the outer diameter of the spindle (68 mm) which precludes using the off-the-shelf "Universal DTI Holders" (which seem to only cope with diameters up to 50 mm) and because to make one myself I would need to start with a big piece of metal or make something a complicated shape. For aligning holes very accurately, I mount the DTI (indirectly) in a chuck.

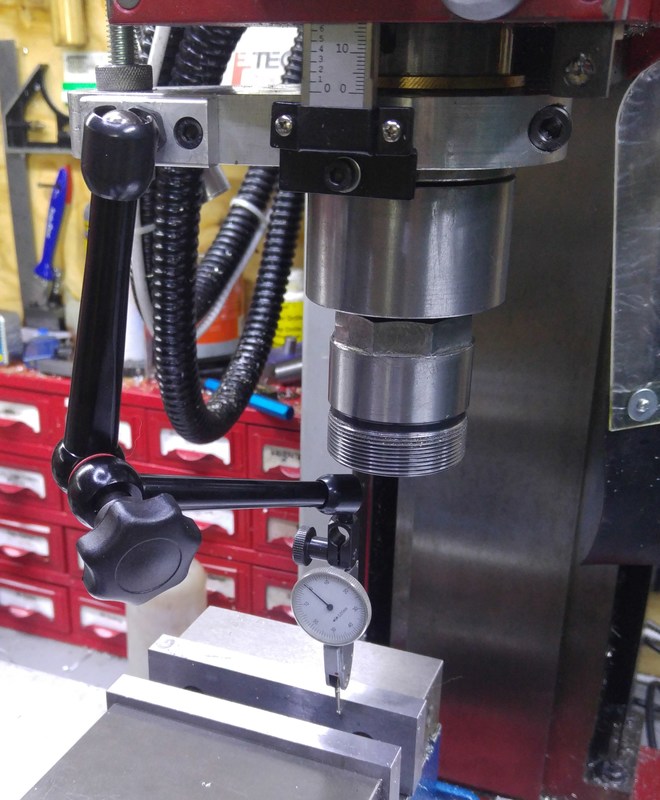

For aligning a workpiece with the travel of the table, the DTI shouldn't be mounted on a rotating part as this can introduce inaccuracies. I found that my milling machine was lacking convenient flat surfaces to mount the magnetic base (the only real option was on the milling machine base, behind the table, but this can make it hard to get the DTI to the right position). The base has an M8 hole tapped in the top and this is used to attach the ball-jointed arm. The arm has a dovetail for mounting a lever type DTI and an 8 mm clamp hole for a dial gauge. I use dial gauges a lot more than DTIs as they can withstand a bit more shock such as when you're adjusting a vice with a hammer.

Therefore, I modified my depth stop by adding a 20 mm × 10 mm plate with an M8 tapped hole in the middle. This plate moves the base of the ball-jointed arm out a little further, which means the arm can be stored out of the way when not in use:

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.