Table Protection

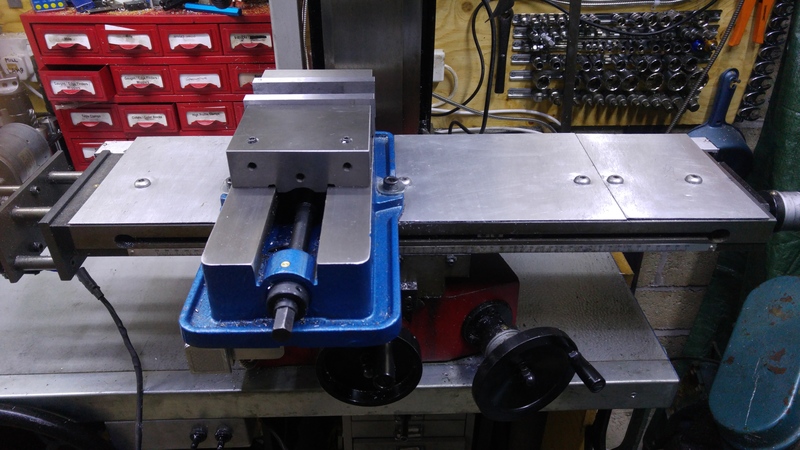

I really dislike cleaning out t-slots. It's not too bad when milling steel as a powerful magnet can be used to do a lot of the work, but aluminium just gets everywhere. I've seen a few pictures on-line where people have fitted wooden boards to the milling table, typically with a block attached to the bottom to hold the board in line with the t-slot. I didn't have any suitable sized wood and thought it would be interesting to try making this out of 1 mm thick aluminium. Rather than using a block on the bottom, I've just drilled 10 mm holes in the aluminium plate to hold it in place with some button-head cap screws.

The disadvantage of this is it takes a few more seconds to remove the plates, but it really doesn't take very long. Advantages are:

- It is strong enough to hold its structure with small segments, so I could cut a little square section to go right up to the screw that holds the milling vice down. This stops swarf from going down that hole.

- It is thin enough that I can place magnetic bases onto the table and they are still attracted to the table beneath the plate (albeit with substantially less force than when attached directly).

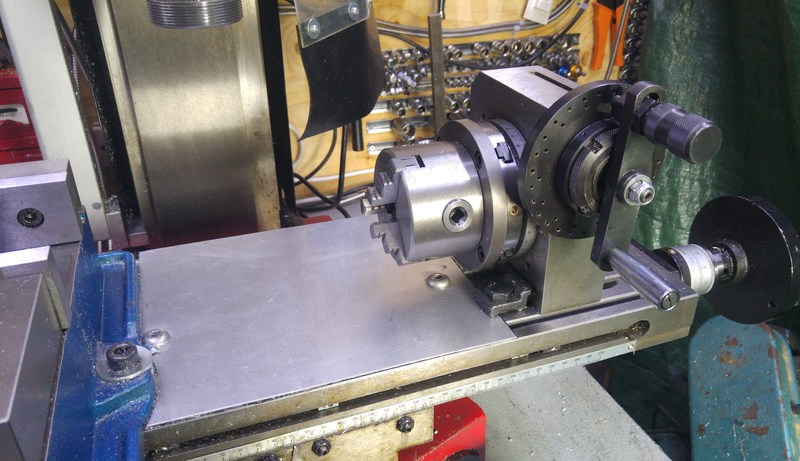

I've made the plate in multiple sections. One covers the area to the left of the vice. The area to the right of the vice is covered by two more. Initially I did this due to the size of the aluminium plate that I had available. However, it has proven invaluable as I can fit my dividing head to the right-hand end of the table (without removing the milling vice) and most of the swarf remains on the aluminium sheet rather than going into the t-slots:

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.