Woodturning Lathe Build Process

Page 50 of 50

Posted 26th December 2025

The work described in this post actually started a few weeks ago and had the last operation completed a few days ago, but it seems to fit into the narrative a bit better here than before I'd given some context to the general upgrade work being done on the lathe.

Another of my various skip finds was this large aluminium disc, which had obviously had some milling done on it at some point:

The first thing I did on that plate was to hold it in the milling vice with the flatter of the two faces at the top. Clamping it was a bit unconventional in that I just placed a couple of parallels on the top of the vice and then clamped it in place with some F-clamps. I could then drill and tap some M5 holes spaced around the centre:

I'd considered making an M33×3.5 mm mount for the big plate, but I didn't have any steel of a sensible size (and the skip didn't provide me with anything appropriate). Buying a piece of steel would have cost more than this (£9.79) face plate from aliexpress, so I went with the easy option. I needed to modify it a little as I wanted countersunk holes in the rear face. I started with a countersink but it was struggling to cut (and having a relatively short shank I also managed to mash the chuck into the part):

I switched to a spotting drill (which also has a 90° included angle) and that did a much better job:

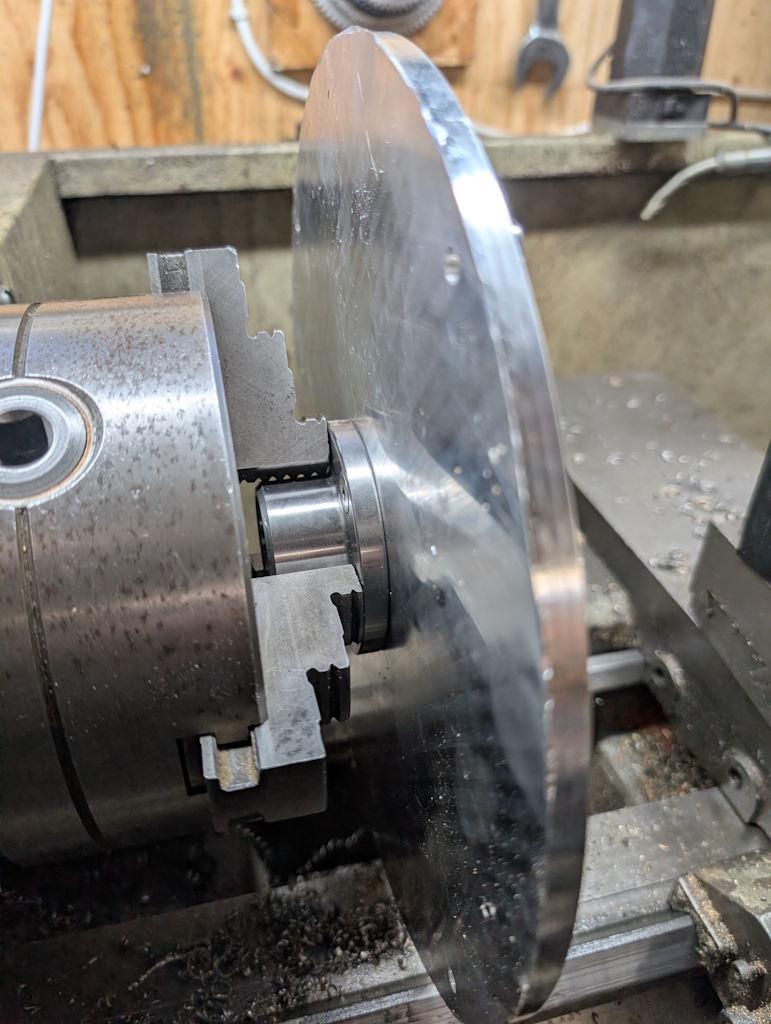

I cleaned up the "oops mark" on the lathe and then screwed it to the big aluminium disc. I then mounted the face plate in the three-jaw chuck for roughing out the surface:

Here you can see the overly long screws I used to attach the two parts together. You can also see that it only just fit on the lathe:

Here's an action shot of me cleaning up the face:

This was how I left it a few weeks ago, with a fairly clean surface but, critically, no real guarantee that the face or rim was concentric as I'd been holding it on the outside of the faceplate rather than on the chuck register:

When I'd finished turning the new spindle and had it mounted in the soft jaws of the chuck (which, if you remember, were turned to size in situ and hence should be very accurately concentric with the lathe axis), I mounted the big disc on the spindle-to-be and did a final light skim cut of the outer diameter and of the face, giving me a big flat and true 250 mm disc that can easily be mounted on the wood lathe:

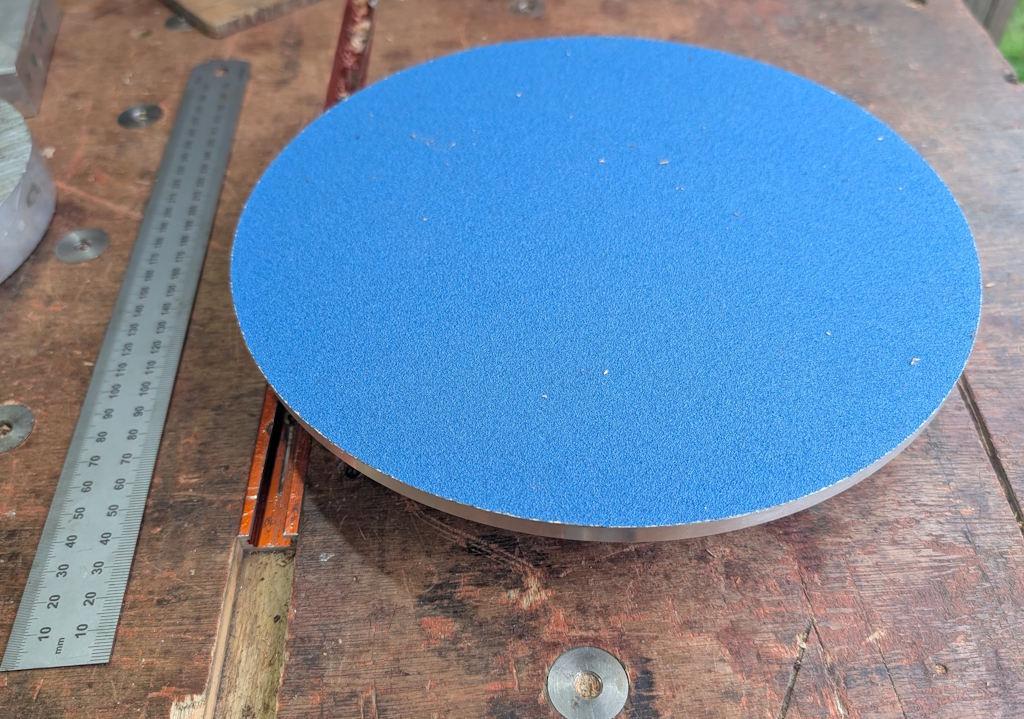

If you haven't guessed already, this photo should explain its purpose:

Being aluminium and not too thick, it should be relatively easy to remove the self-adhesive sanding disc when it wears out as I can just heat the back of the plate up until the glue gives way. I can then clean any left-over adhesive with acetone or similar before fitting a new disc.

I don't often sand anything but I can see it being a useful thing to have for occasional use and it'll be nice to have it as a lathe accessory rather than requiring a separate machine that I'd have to find somewhere to store.

One of the other lathe upgrades I'll do soon (with one of the other aluminium skip finds from one of the earlier photos) is to make a banjo-mounted table that can be used when sanding if desired.

Page 50 of 50

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page