Woodturning Lathe Build Process

Page 49 of 50

Posted 24th December 2025

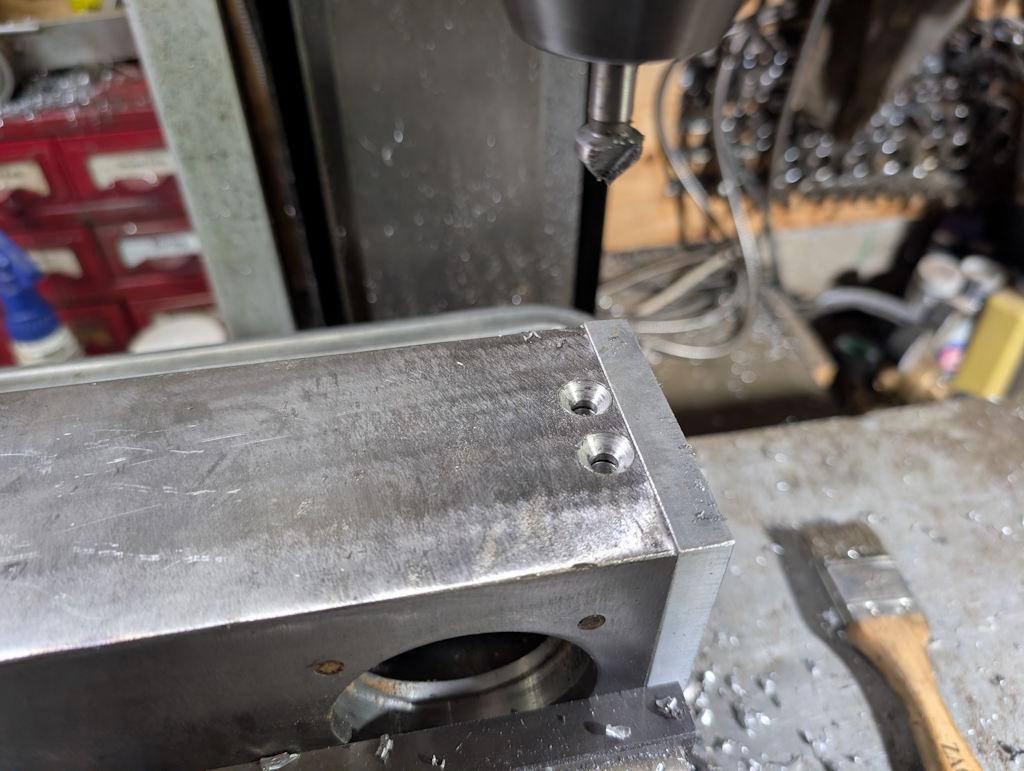

Today I continued with the headstock. The first thing I did was mount the headstock in the milling vice and, with the new lid clamped in place, drilled two 6.2 mm holes in each side and also countersunk them:

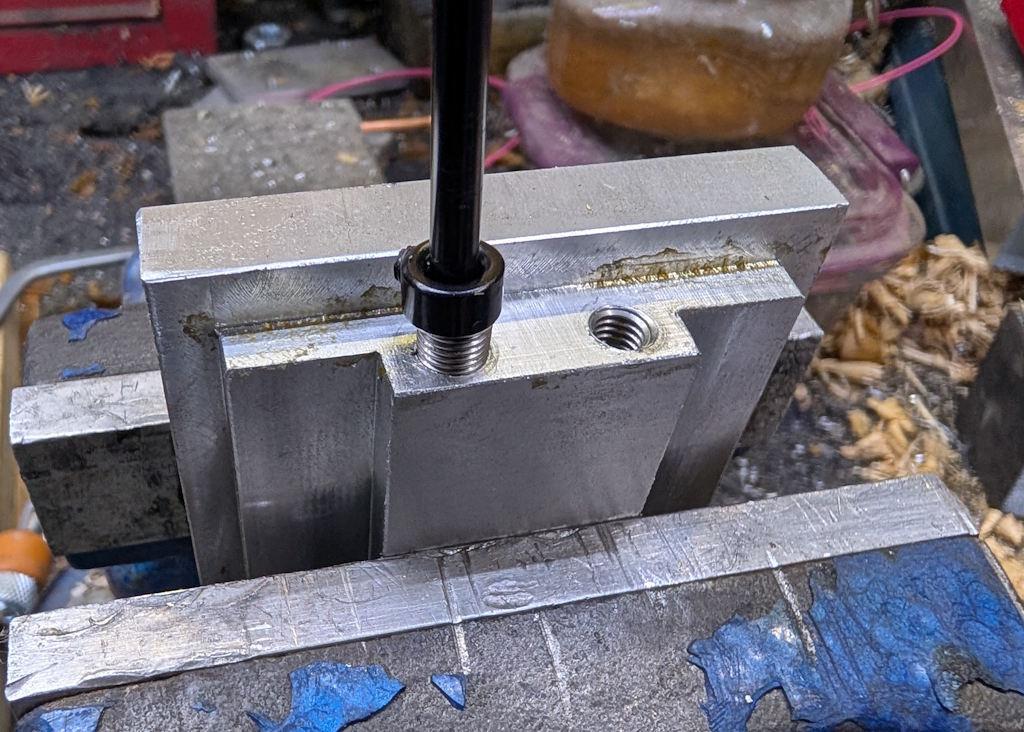

The holes in the lid then got tapped to what I think is probably M7.2×1 mm:

That thread is the one used for an M6 V-Coil (another brand of Helicoil) insert, which was fitted in each of the four holes:

The main reason for using a thread insert is that it'll make the thread stronger and more resilient to having screws inserted and removed repeatedly (as the wearing surface of the thread will be steel on steel rather than steel on aluminium). One fringe benefit of doing it that way was that I could drop a screw into the drilled and countersunk pocket and check that the countersink was deep enough (I could do this because the tapping size for the coil insert is bigger than the diameter of the screw).

With that done I could fit the lid:

Three of the sides of the headstock then got some holes drilled. I started with the rear of the headstock, which got four M5 holes added (two with V-coil inserts and two just tapped M5 directly):

You might notice that one of the lid attachment screws is missing in that photo. That's because I've only got three of them: I need to order some more!

Those holes will be for mounting the chuck key and Allen key holder. Previously, that holder had been held on with magnets but it occasionally got knocked off so I've decided to make a new one that will get screwed in place. Four screws is probably excessive but what the heck.

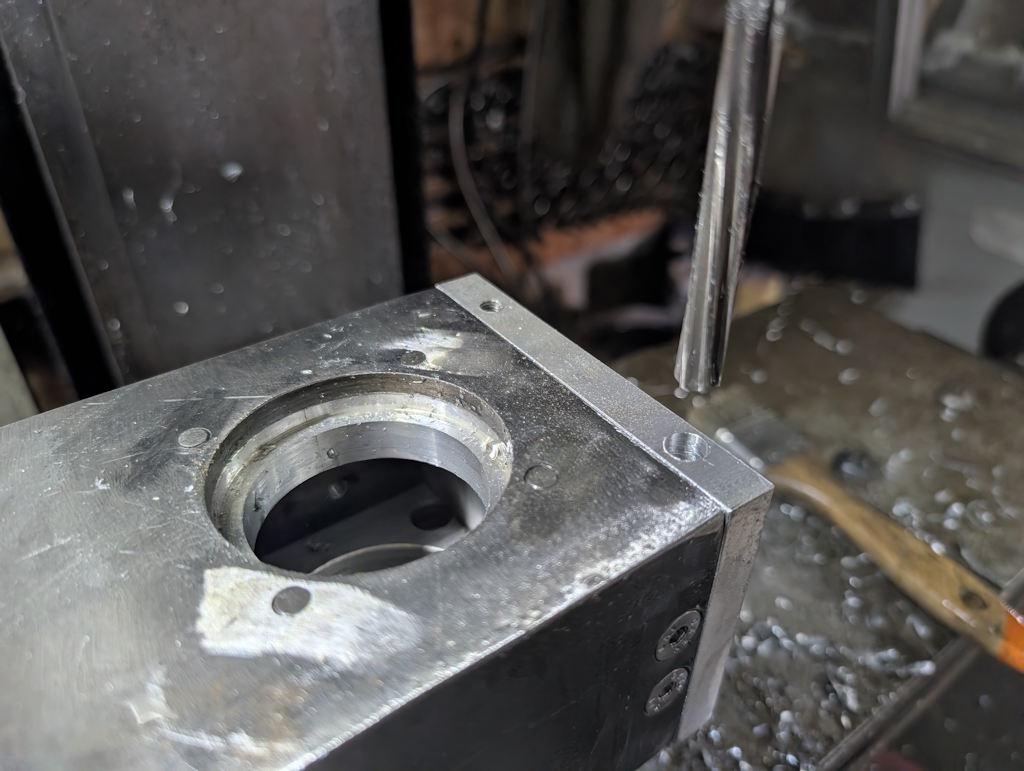

The front got two holes, a big one for the tommy bar (which I drilled 10 mm then finished with an end mill as I couldn't get the head up high enough to leave clearance for my 12 mm drill bit) and a smaller one to mount the cover for the big hole:

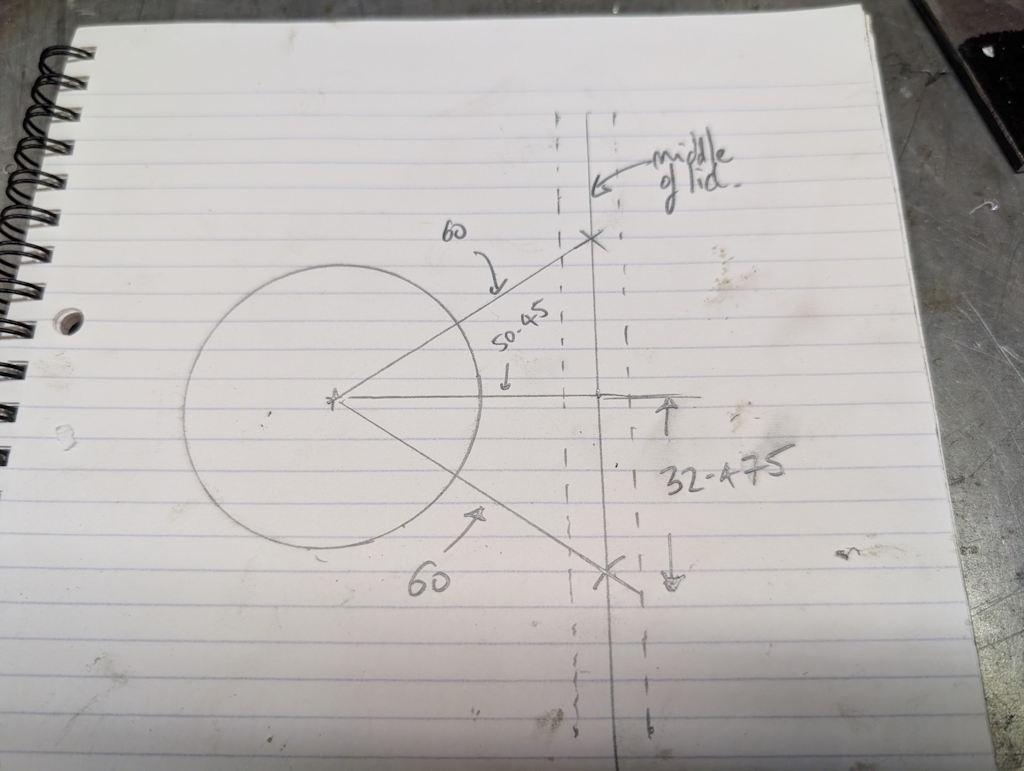

Finally, the left-hand side got two holes. These have different purposes to each other but share the same requirement: I want them to be roughly in the middle of the lid (top-to-bottom) and I want them to be 60 mm from the centre of the spindle axis. After measuring the distance from the centre of the bearing hole to the top of the centre of the lid, Pythagoras came to the rescue:

That simple bit of maths gave me the locations to drill and tap an M5 hole and to drill and ream an 8 mm hole:

The last job to do while the head was still assembled was to run a chamfering tool around the outside, chamfering the edges of the lid at the same time as the body.

I also put a heavy chamfer on two sides of the bottom, as the raiser I added is slightly narrower than the headstock and this should soften that edge. I struggled to cut that chamfer and only after doing the second one did I realise that I hadn't tighten the collet chuck! I'm frankly amazed that I managed to do any of the other chamfers.

The final headstock job (at least until I think of any others!) was to remove the lid and cut a 4 mm wide slot in one of the edges:

We've got family visiting from tomorrow (and I've got to cook Christmas dinner) so I'm not sure when I'll next get into the workshop. However, I have already done (but not documented) one other job on the lathe so I might find some time to write that up and post about it sometime over the next day or two.

Page 49 of 50

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page