Woodturning Lathe Build Process

Page 52 of 52

Posted 28th December 2025

I didn't feel quite ready to work on the banjo yet (still more thinking to do) so I thought I'd get on with another job. I stared with another bit of left-over 50 mm EN1A bar, which got faced, skimmed and drilled 13 mm:

After chopping it off with the horizontal bandsaw, I mounted it back in the chuck with a 3D-printed "spider" and cleaned up the sawn-off face:

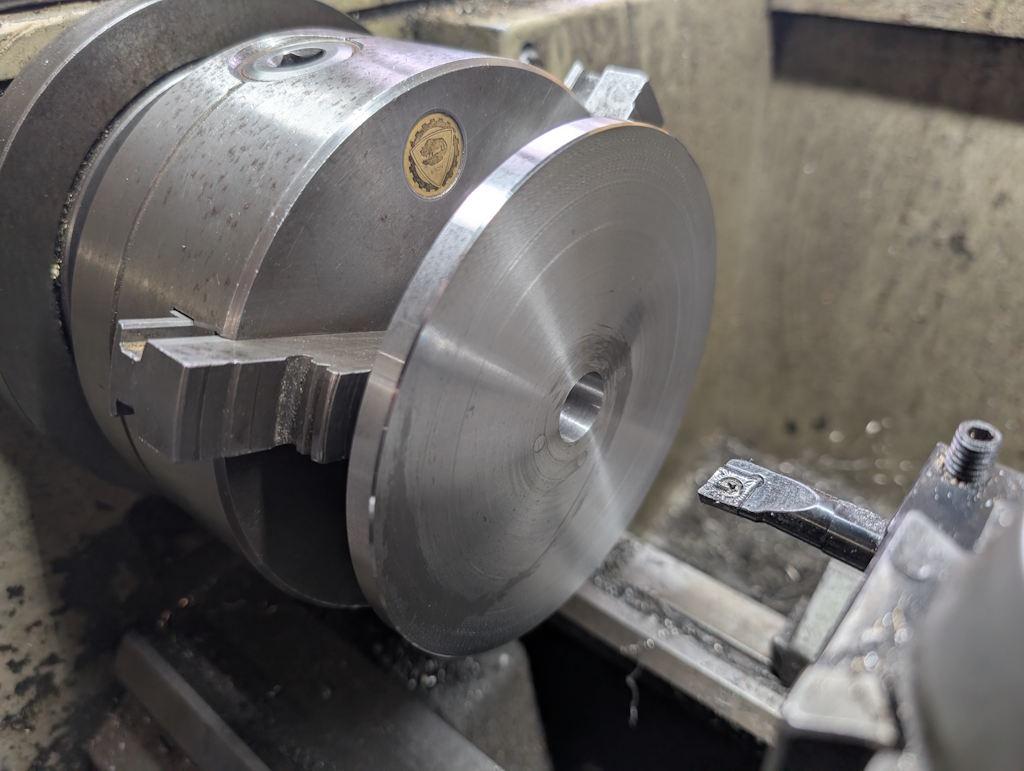

Next up was a big bit of skip-dive stainless steel. That got held in the outside jaws of the three-jaw chuck:

I then cleaned up one face...

... then flipped it over, cleaned up the second face (bringing it down in thickness as far as I could without hitting the jaws) and then again drilled 13 mm through:

I knocked up this quick and simple jig for holding both parts on the milling machine. The end has been reduced to 13 mm for a short section and it has an M8 tapped hole in the end:

The lathe axis got centred on the axis of that 13 mm section and then I mounted the 50 mm piece on the jig and drilled and counterbored for M5 cap screws:

That part then got removed and the bigger one fitted and this time I drilled and tapped M5:

The last milling job for now was to mount the smaller piece on end and cross-drill and tap M8:

M8 is a bit excessive for a part that thickness, but it has the advantage that the grub screw has a 4 mm AF hex socket in it, which is the same as that in an M5 cap screw or an M6 countersunk screw. Wherever possible, I'm using those types of screws on the lathe so that a single Allen key can be used for as much as possible.

Four M5 cap screws could now be used to join the two parts together:

I tightened those cap screws up as much as I could: all being well they'll never be undone.

With the two parts joined together, I mounted the assembly back on the lathe (gripping on the outside of the smaller diameter part) and (very slowly) bringing the larger part to final thickness (8 mm) and diameter (142 mm), before boring out the centre hole to 20 mm:

That took most of the morning (I had to run the lathe quite slowly or it would run out of power trying to cut near the outer diameter of that stainless disc) so I've stopped for lunch now. More to follow...

Page 52 of 52

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page