Woodturning Lathe Build Process

Page 51 of 53

Posted 27th December 2025

Today was all about the tailstock. When I made the tailstock originally, I just used what is essentially a nut to fix it in place. It wasn't quite as low-tech as a nut: it was a cylinder of steel with a thread tapped in the bottom and a sliding tommy bar going through it. Tightening and loosening the tailstock was a case of spinning the tommy bar round clockwise or anticlockwise.

That worked okay, but the box section that forms the bed isn't perfectly even and in some places I'd find myself needing to move the nut by as much as half of a turn, at which point I had to slide the tommy bar across. Not exactly a major issue (it certainly hasn't stopped me making stuff with the lathe), but a cam-lock tailstock would be nicer.

It's not the first time I've made one (I upgraded my first metalworking mini-lathe to have a cam-lock tailstock) so I had a fairly good idea of what I was doing before I started. When I did the original cam-lock tailstock for the mini-lathe, I followed a design I found on-line but it broke after a year or so and I ended up beefing it up a bit. For this one I decided to err on the side of strong!

I started with these three bits of EN1A:

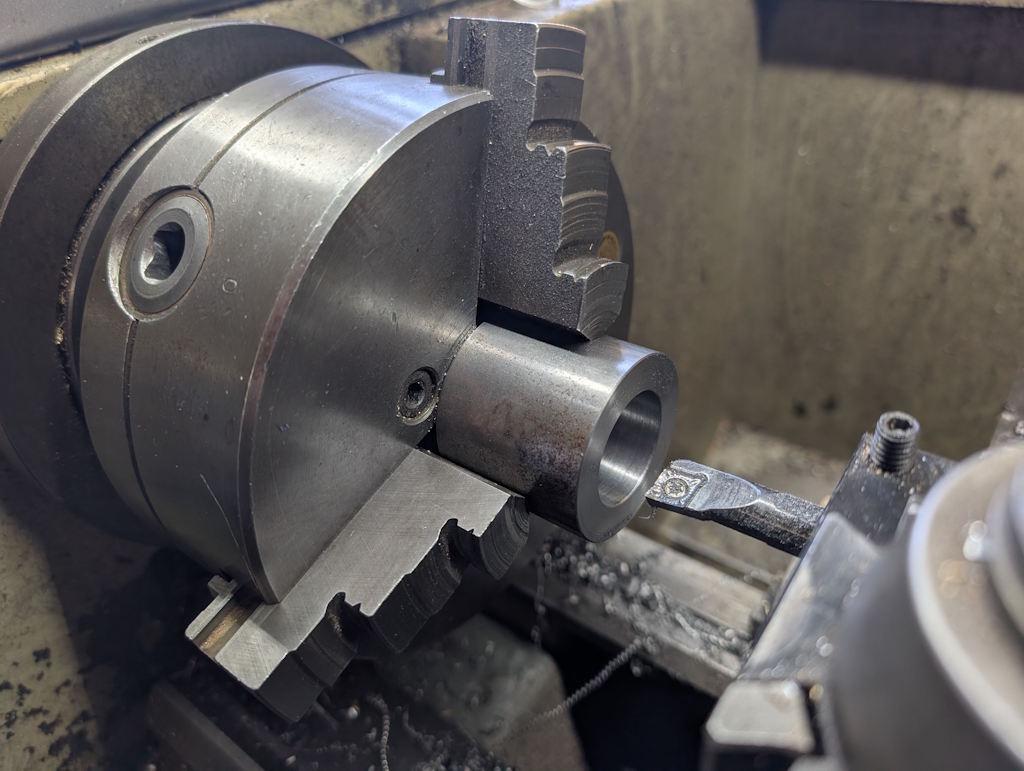

They're 20 mm, 30 mm and 50 mm diameter. I later also used a bit of 10 mm diameter EN1A as well. I started with the largest piece, which was faced off on both ends and then drilled and bored out to 30 mm to a depth of 40 mm (in the 45 mm long piece):

The 30 mm bar got the outside surface cleaned up and then I drilled and tapped a shallow M10 hole in the bottom:

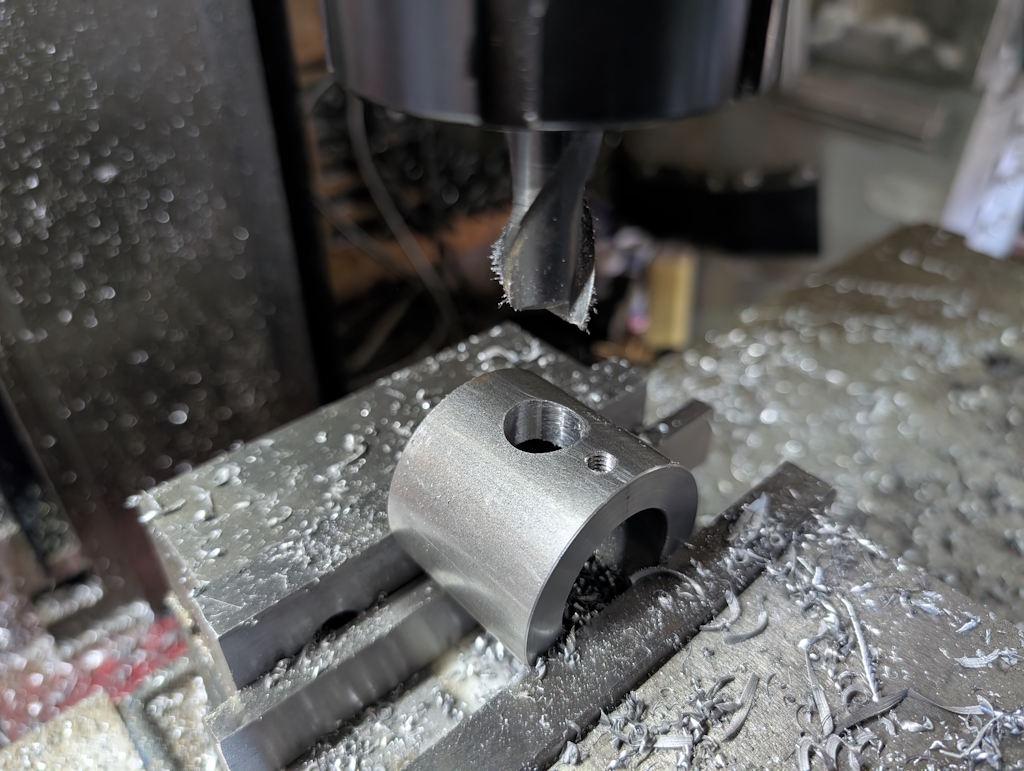

With those simple jobs done, it was over to the milling machine. I started with the bigger bit, which got drilled through 11.5 mm and also got a through 5 mm hole, which was partially tapped M6 in the more accessible side (the other side got partially tapped after it was removed from the mill vice):

The M6 thread there is for a short grub screw. The only purpose of the grub screw is to block the hole and stop sawdust from getting in (hence it only being partially tapped: the grub screw will tighten into the hole without protruding into the bore or out of the outside diameter).

I only actually wanted an M6 hole for a blanking plug on one side of the part but the side I wanted it on was the underside and I wanted it to be parallel with the other hole so it seemed easiest just to drill all the way through and add a blanking grub screw on both sides.

The bigger hole is to be 16 mm on the upper side and 12 mm on the lower side. For the upper side, I made the 16 mm hole with an end mill:

For the lower side, I converted the 11.5 mm drilled hole into a 12 mm hole with a reamer:

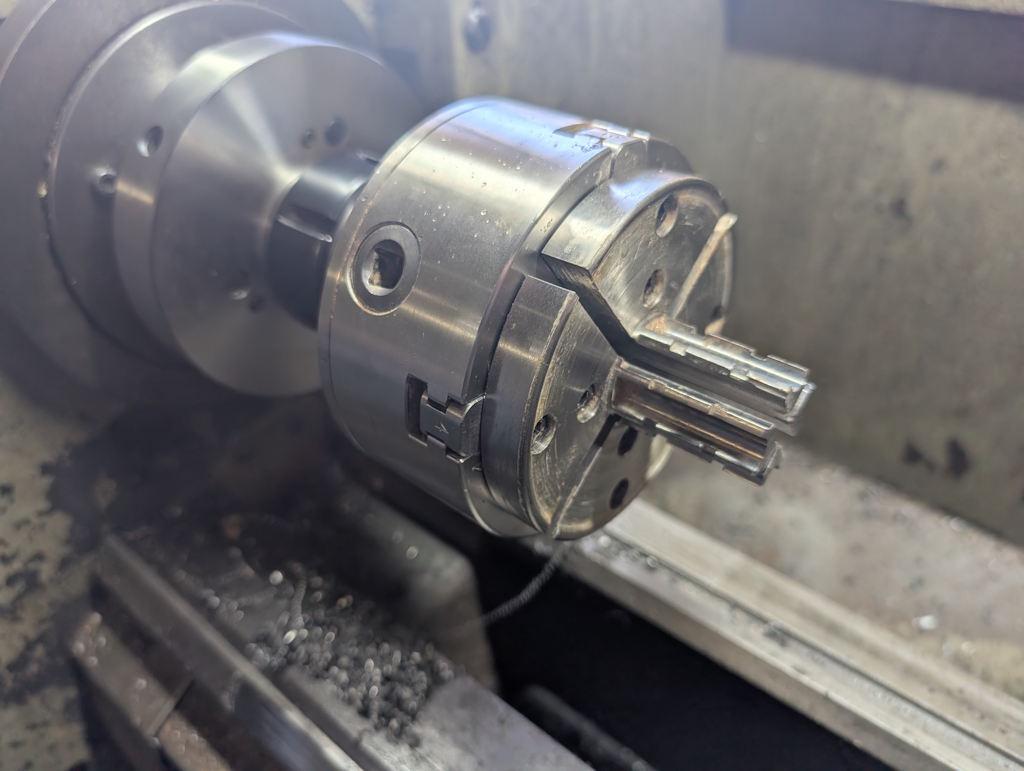

The outside surface of this part has some light surface rust. Since it was a short piece when I first started working on it, I couldn't turn the outside surface (as it was gripped in the jaws). I don't need a turned finish, I just want the rust gone. Rather than making something custom to hold on the inside bore, I thought I'd make use of the stub spindle I made a few days ago:

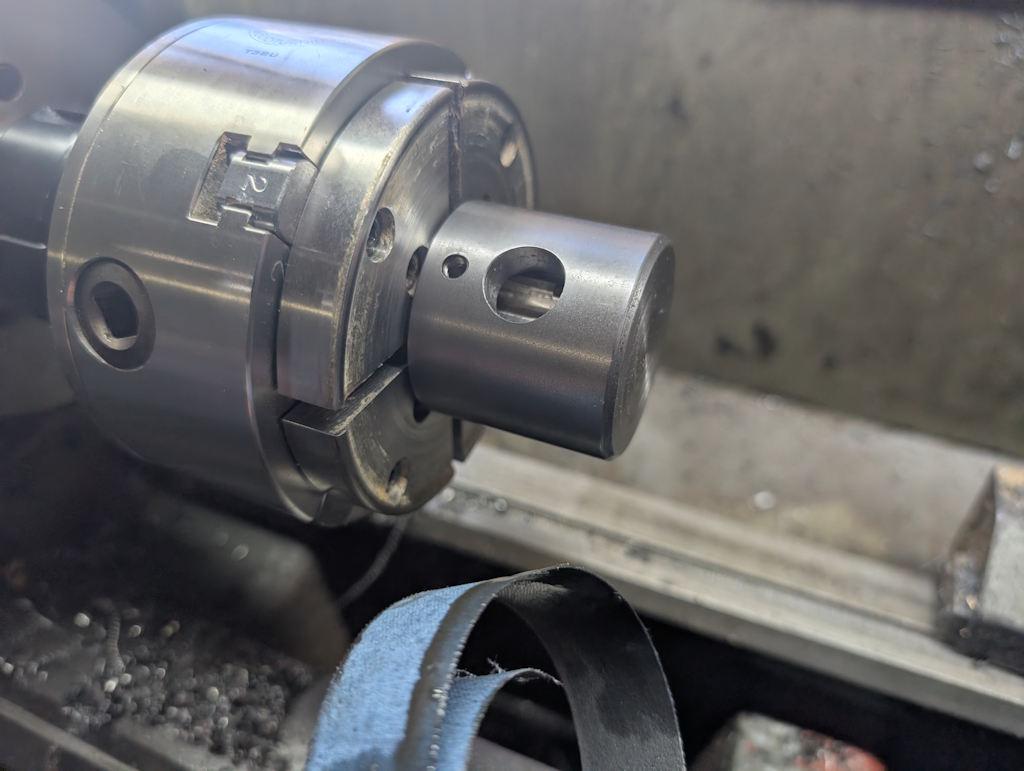

I fitted one of my woodworking chucks to that spindle and fitted some jaws that I recently bought second-hand on ebay. Conveniently, they're designed to hold on a 30 mm bore:

I don't think that would be a very good set-up for taking any substantial cuts with a lathe tool, but it was fine for spinning the part round and cleaning up the outside with 240 grit emery cloth:

The other part already had a smooth outside surface as it had been given a skim cut on the lathe, but it still needed the cross holes, this time a 16 mm hole all the way through and a smaller M5 hole half-way through:

That M5 hole will have a grub screw in, which will lock a bit of threaded rod into the tapped hole in the bottom; removing the M6 blanking plug in the outer part will allow access to the grub screw if I want to remove the threaded rod later.

The next job was to work on the tailstock. This needed a 20 mm hole drilled in the rear face. I say drilled, but I had to use slot drills and end mills for this job as the surface is sloped and hence a drill bit wouldn't have worked.

While I had it clamped in the mill vice, I also drilled and tapped an M5 hole down in the corner:

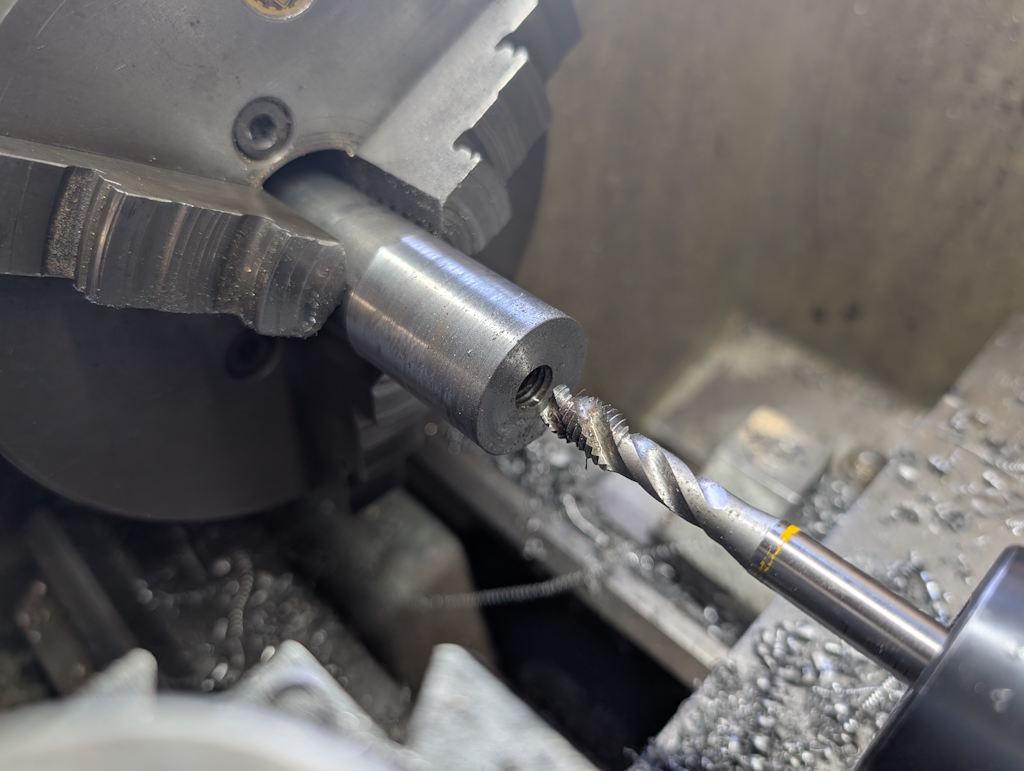

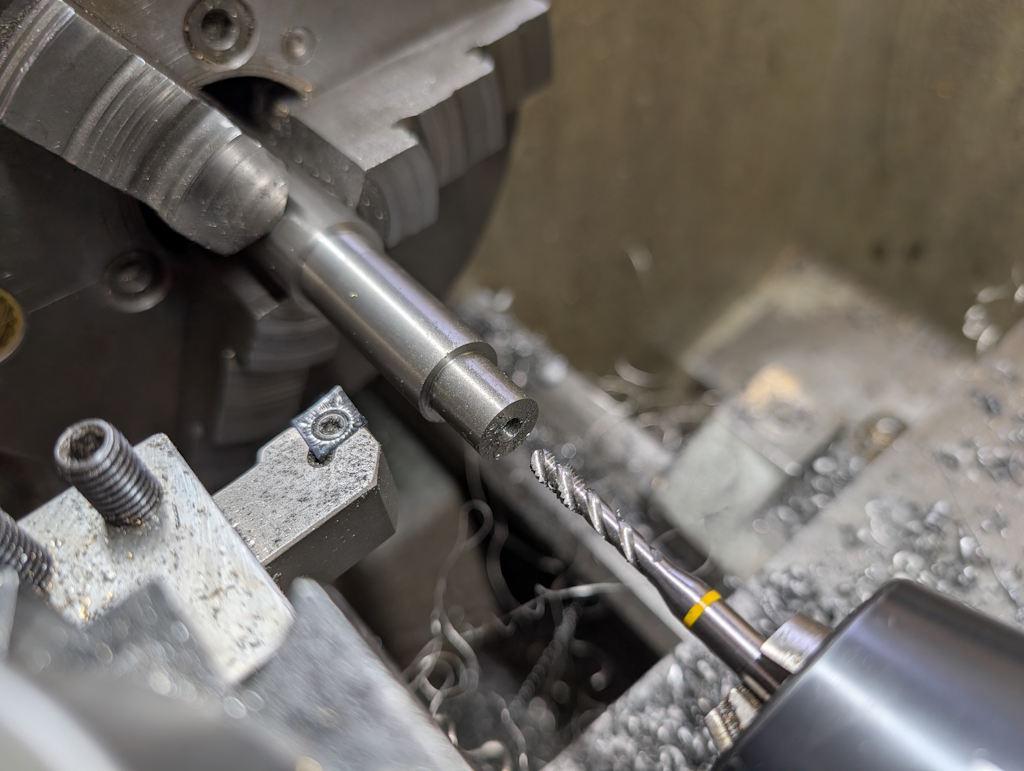

The final significant job was the cam. This started off as 20 mm EN1A, which got turned down to 16 mm for a bit and then turned down to 12 mm for a bit. The tailstock live centre was then removed and the end got an M5 tapped hole made in the end:

It then got remounted in the lathe but with a couple of feeler gauge sheets (totalling 1 mm thickness) in between one of the jaws and the part. I could then skim most of that 16 mm diameter down a bit more, resulting in an offset section that will lift and release the 30 mm diameter nut.

The other end got mounted in a collet and tidied up a bit and then it got taken over to the milling machine to gain a tapped cross-hole:

Without taking any photos, I made a couple of other simple pieces: a 10 mm shaft with an M8 thread on each end and a 16 mm tapering knob with and M8 tapped hole in the end:

They get assembled like this:

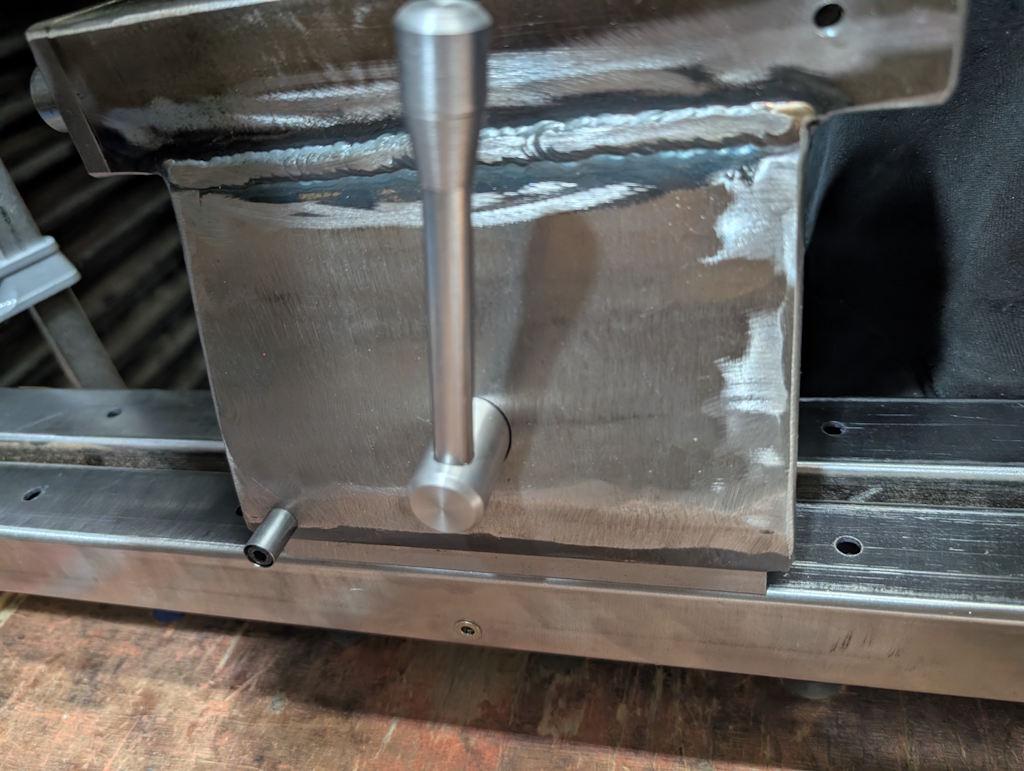

I also made a very simple small stub shaft (just a bit of 10 mm steel with a counterbored hole in it for an M5 retaining screw) to go into the tapped hole in the corner of the back of the tailstock. It was then time for a test drive. The lathe bed is in pieces at the moment, so I just got the welded box section pieces and clamped them on top of some pieces of wood on the bench. That was good enough to test the operation:

This photo from the rear of the lathe shows the cam in the unlocked position, resting on that little stub shaft (which stops it dropping further down behind the lathe and potentially starting to lock again):

This photo shows the cam in the locked position. It seems to hold onto the bed extremely rigidly and, if necessary, it could still be rotated further if more locking force were ever required:

That's all the changes I'm making to the tailstock, except that I'm planning to paint it (and other parts). I might try and deal with the weld bead on the back of the tailstock before painting (if I can find a good way to get a grinder of some sort to it - my angle grinder flap disc wouldn't get in there). It's not the end of the world if I don't though.

The next job will probably be to work on the banjo. I'm thinking I might add a cam-lock to the tool post mount as well (there's already a cam-lock securing the banjo to the bed).

Page 51 of 53

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page