Woodturning Lathe Build Process

Page 53 of 53

Posted 28th December 2025

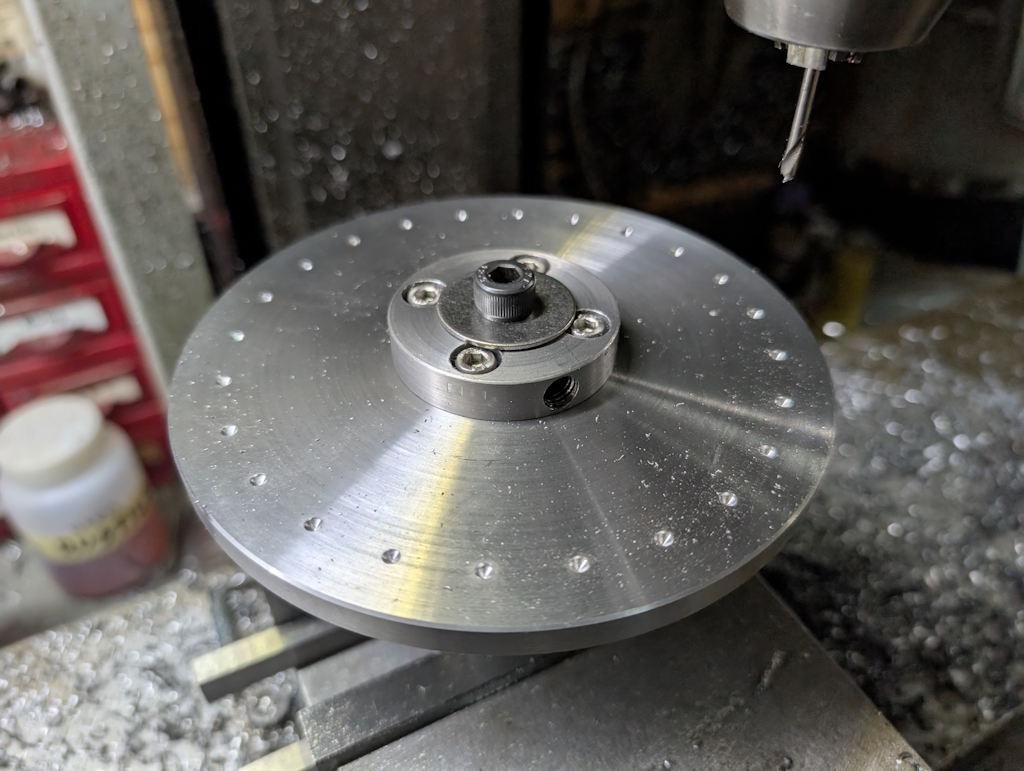

After running some errands, this afternoon saw the completion of this part. I started by making a new jig, which was simply a bit of steel with a 20 mm section turned on the end, a 24 mm section turned concentric with that (the diameter of the latter didn't matter, it just had to be concentric) and an M8 hole tapped in the end:

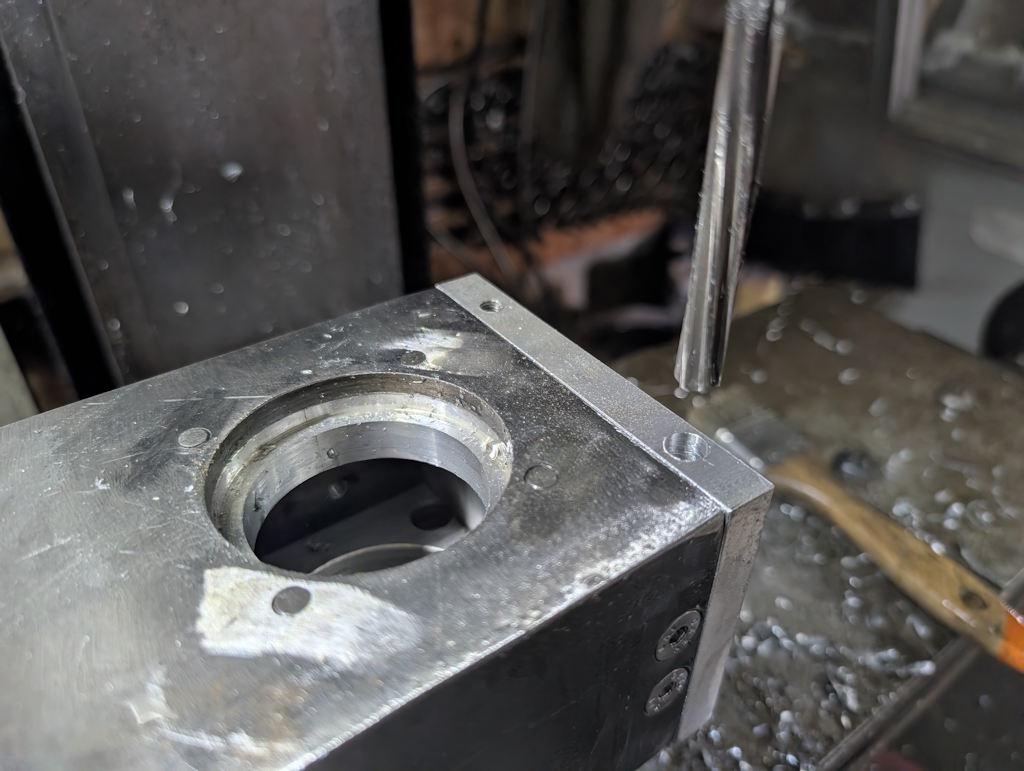

In that photo I'm parting off the bit that hasn't had any turning done on it. That "jig" got held in a collet chuck and the workpiece got clamped down to it. I then used the "PCD" (pitch circle diameter) function of the digital read-out, in combination with an 3 mm spotting drill, to mark out 24 holes, evenly spaced around the outside (on a 120 mm diameter):

They all then got drilled out 2.5 mm and then every other one got drilled out 7.6 mm, deburred with a countersink and then reamed to 8 mm:

I put an M3 tap in the chuck but turned it by hand (there's no way I'm power-tapping M3 in stainless steel!) to turn the remaining holes into through threaded ones:

With all the holes drilled and reamed or tapped, that was the piece almost complete.

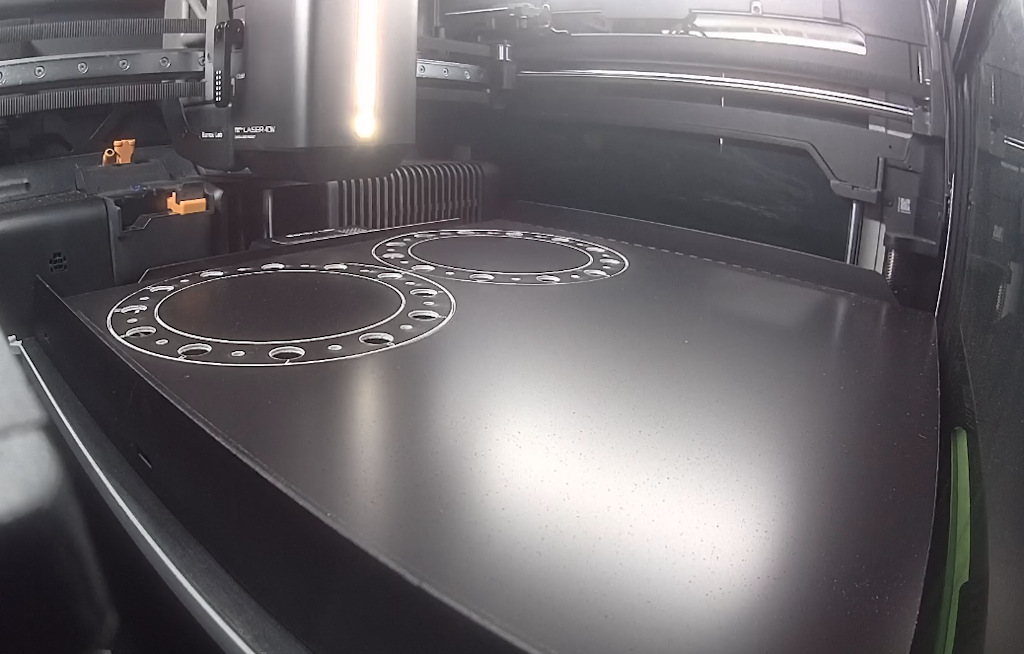

I used the pillar drill with a countersink bit to deburr the reverse side of the part and then used the laser function of my new-ish 3D-printer to engrave and cut out two mirrored pieces from some 1.6 mm thick black-on-white laser laminate:

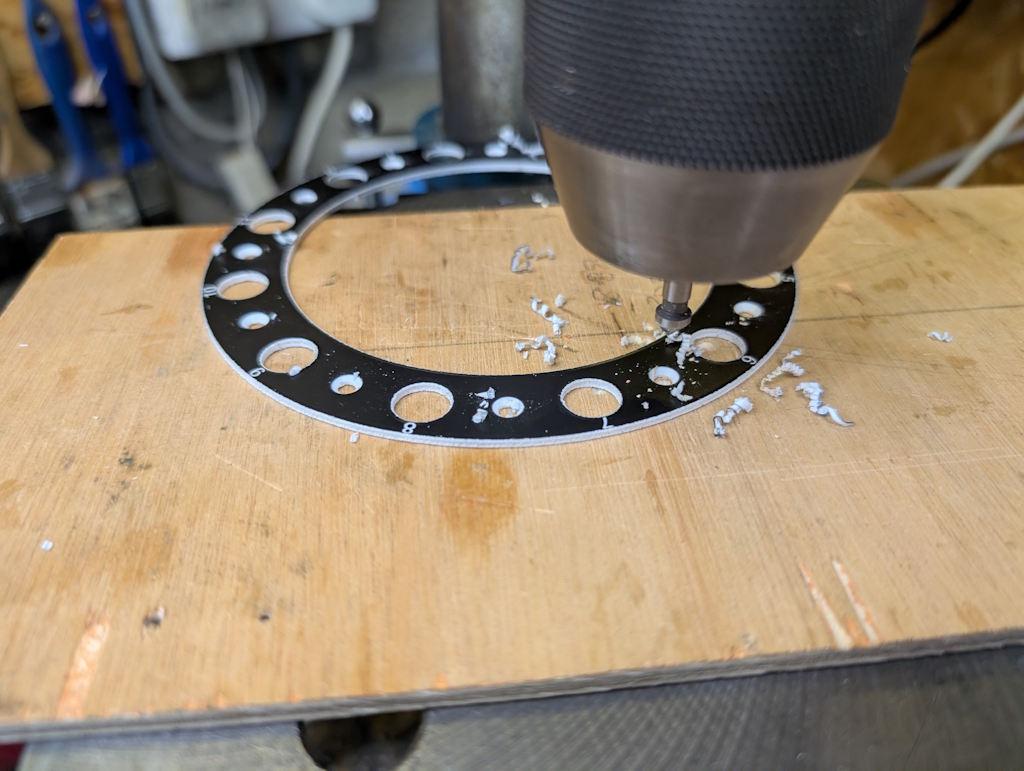

Unsurprisingly, the laser won't countersink holes, so I did that on the pillar drill:

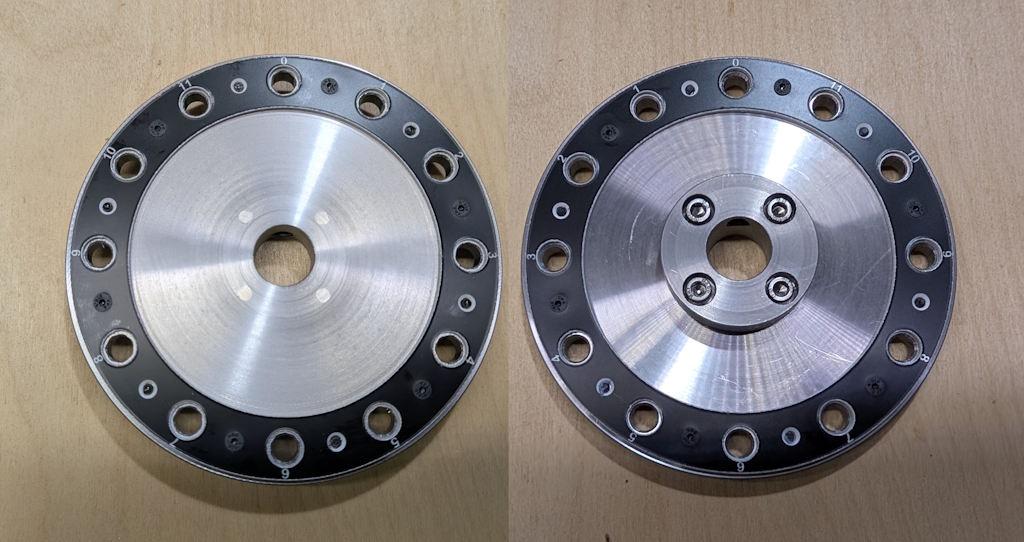

With that, the part is complete, both sides shown in this composite image:

You may notice that the screws holding the acrylic down look a bit odd. I don't have any short enough screws to have one coming in from each side in every hole so for now I've just used a longer one in every other hole. I've got quite a few different screws to get hold of so I'll place an order with KayFast in the next day or so.

In case you haven't already guessed what this is for, this is a dividing attachment for the lathe. It'll get mounted on the rear of the spindle. There will be a sliding bar in the new lid of the headstock (using one of the two holes I drilled in the lid that had to be 60 mm from the spindle axis) that will (hopefully) slide into the holes on this dividing plate and will lock the spindle's rotation, allowing me to add features that are evenly spaced around a turned part.

For interest, the other hole in the lid that also had to be 60 mm from the lathe axis is just for a mounting screw. The only reason it had to be 60 mm from the lathe axis is so that I can stick an Allen key through one of the dividing plate holes in order to loosen/tighten the screw.

Page 53 of 53

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page