Woodturning Lathe Build Process

Page 54 of 55

Posted 30th December 2025

The last couple of days have been all about the new tool post clamp mechanism. There were two aims in this modification. The first was to replace the screw that is used to lock the tool post in place with a cam mechanism, which should make it possible to move the lever further away from the tool post (and hence the spinning workpiece). At the moment it points to the left slightly so I sometimes feel the need to stop the lathe before adjusting the toolpost screw just because of hand/spinning-bowl proximity.

The second aim is to reduce the height of the clamping part slightly. The current one sticks up 25 mm above the banjo; the new one 20 mm.

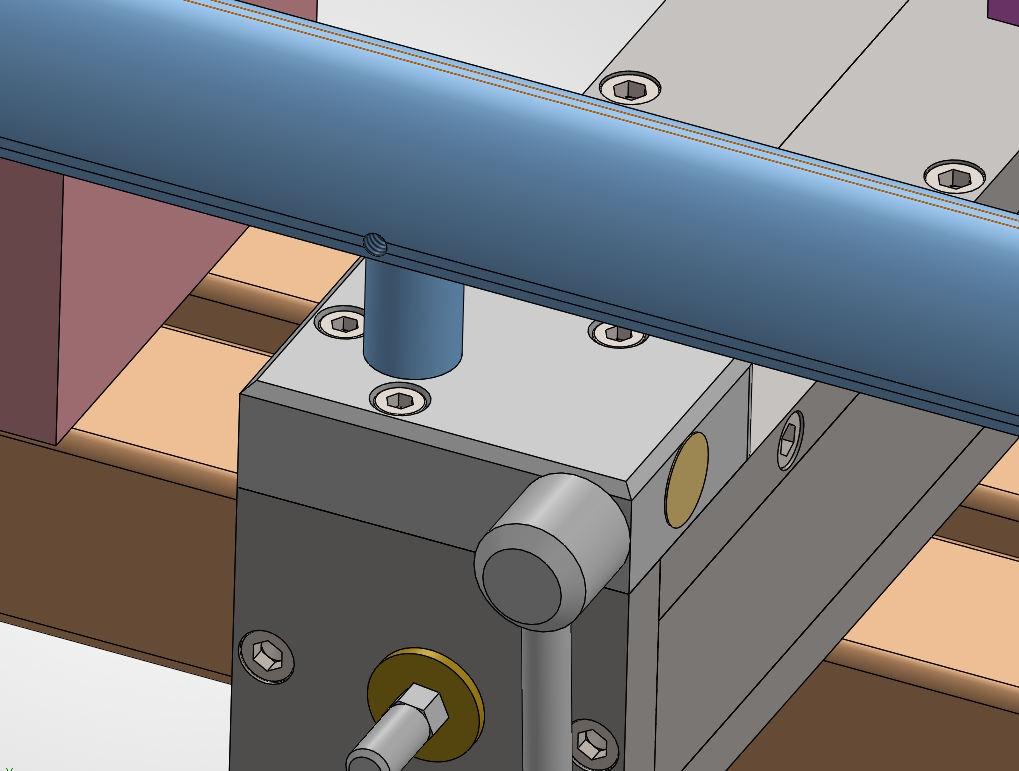

I started by spending quite a while with the CAD model:

This cut-away animation shows how the new mechanism is intended to work:

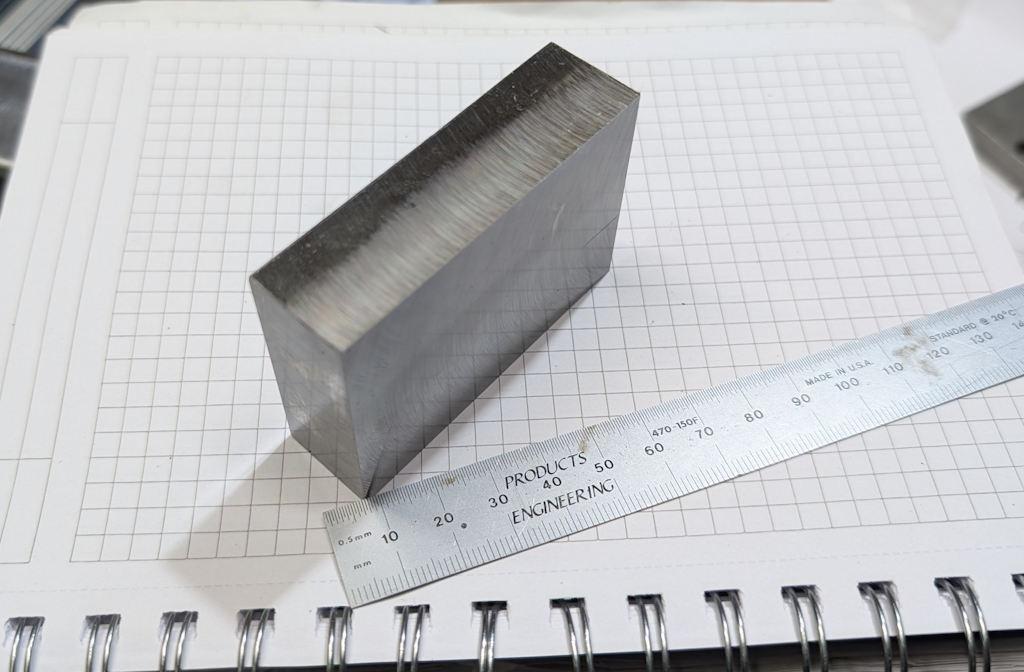

The first job was to make the cuboid that will form the body of the tool post clamp. That started as a slice off the end of a bar of 25 × 50 mm hot rolled steel:

It took a few hours of milling to clean all the hot rolled surfaces and reduce the size down to 20 × 49 × 70 mm, after which I had this shiny block:

This morning I started by drilling the hole in the end of the block (through which the brass clamping piece will slide). That was relatively straightforward, being a 12 mm hole to 49 mm depth and a 16 mm hole to 39 mm depth:

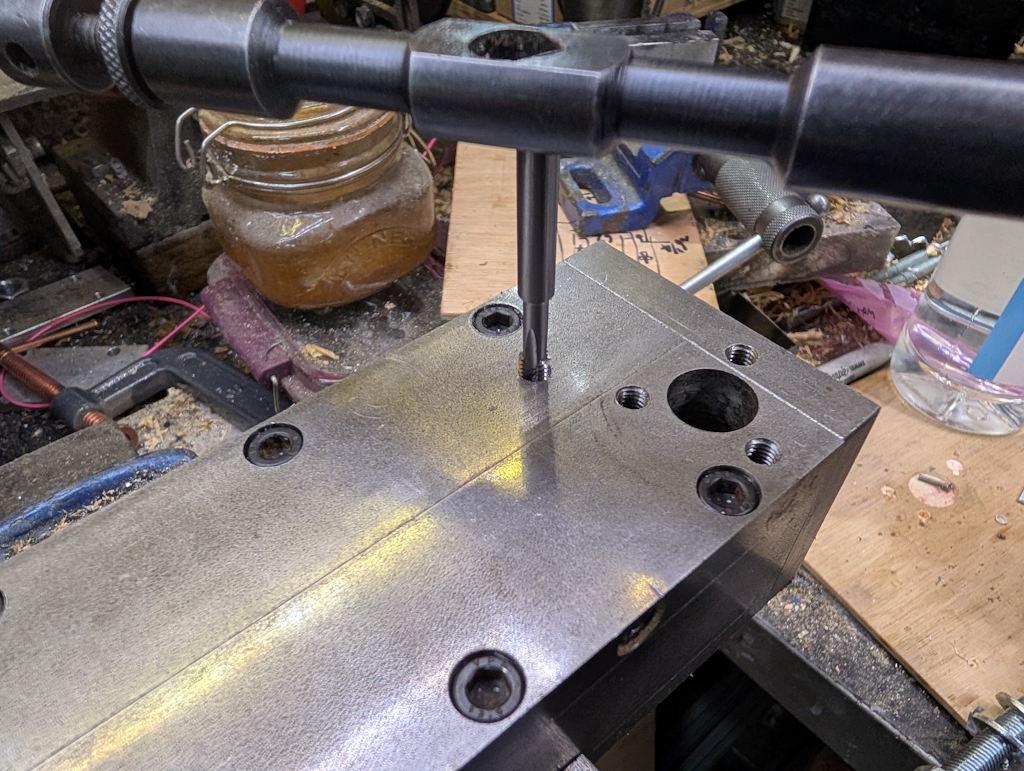

The holes in the top surface were also quite straightforward: three counterbored holes for M6 cap screws and a reamed 16 mm hole intersecting with that first hole I drilled:

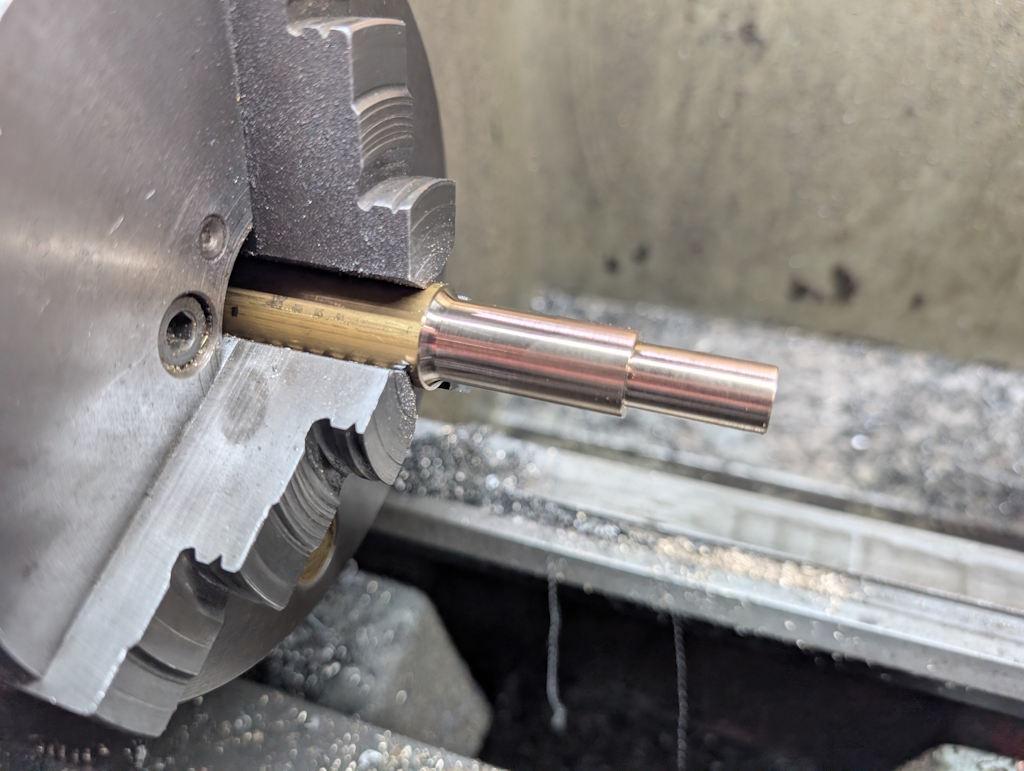

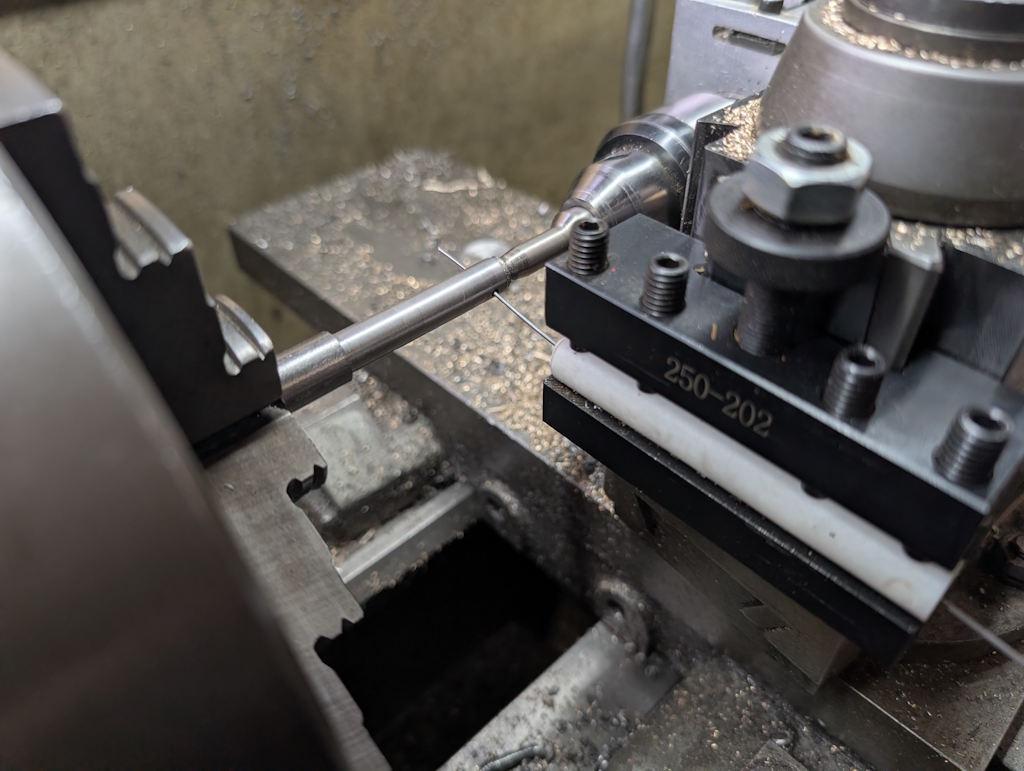

The clamping piece was made from brass (which seems to look like copper in the next photo, but that's just the lighting/camera being odd). The body got turned down to 16 mm and the end turned down to 12 mm:

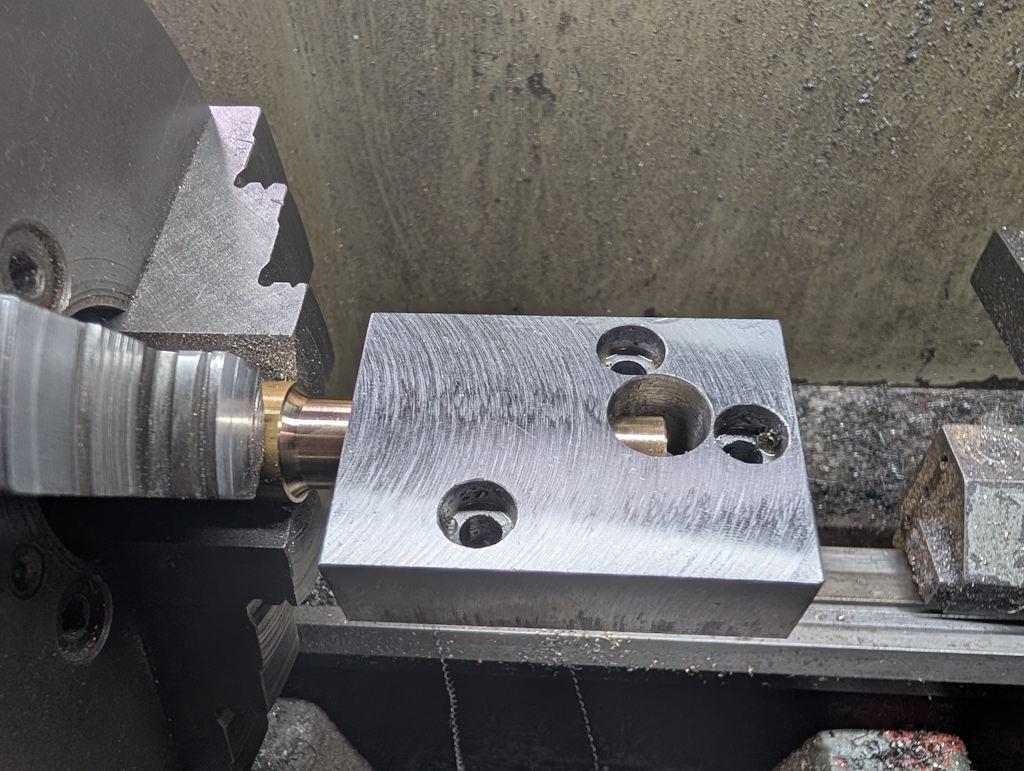

I did a quick test fit in the steel block to make sure it was looking okay before I took it out of the lathe's chuck:

To match the curve in the tool post's shaft, I mounted the brass piece in the milling vice with a collet chuck and used a 16 mm end mill to cut into the end:

I wanted to drill the last hole in the big block with the two parts together. If I pushed the brass piece into the hole and just attacked it with a drill bit, the hole could end up at the wrong angle and more than likely in the wrong place as well. If I put a 16 mm bar in the hole and clamped the brass piece to that, it would ensure the right orientation but the brass clamp would never move deep enough into the hole to actually clamp.

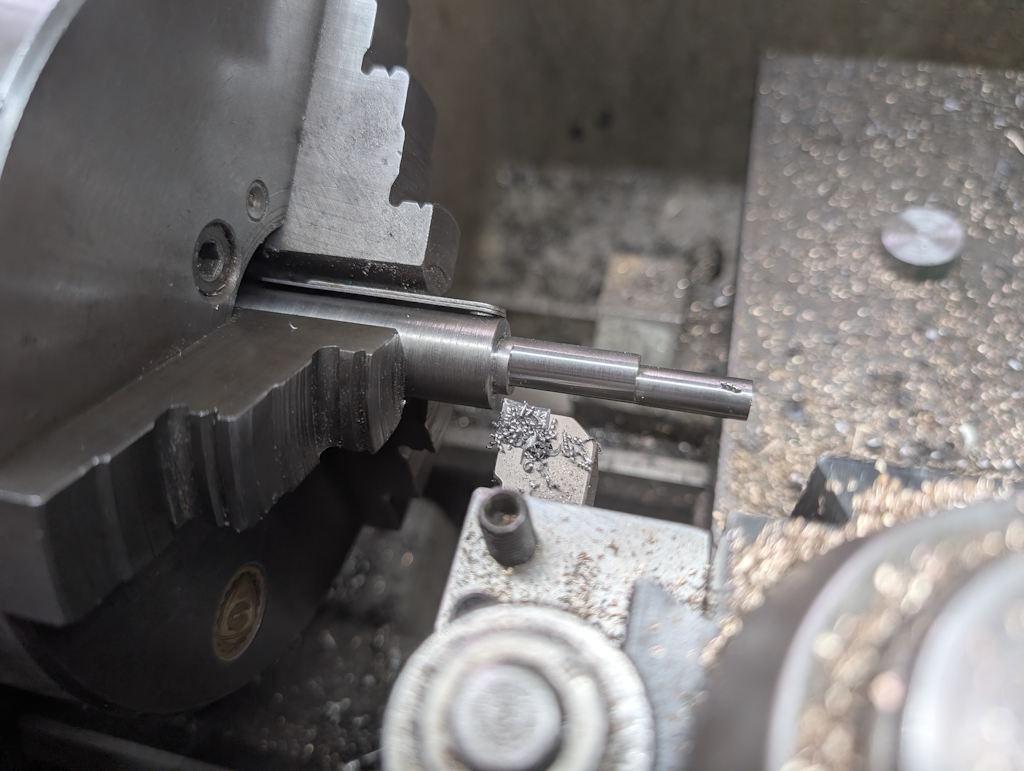

As an alternative, I dug out an off-cut and turned a section down to 16 mm before reducing the central portion a bit further (to 15 mm diameter):

That half millimetre reduction in radius means that, when clamped together, the hole in the brass piece was drilled with a bit of a protrusion into the tool post hole:

The first two parts complete:

Making the cam followed much the same process as the last one, with the first two diameters and the tapped hole in the end done as usual in the lathe before making the cam with some feeler gauge pieces shoved between one of the jaws and the part:

After drilling and tapping the cross hole for the tommy bar and finishing the bar to length, I found that the cam needed a bit of tweaking, so I put it back in the lathe (with some copper tape protecting the part from the jaws) and took 0.1 mm deep cuts at a time, testing with the rest of the assembly and the tool post after each cut:

With that, all the core parts were made and it was clamping the tool post very effectively. However, when the cam is unlocked, there's nothing stopping the brass clamping piece wandering into the tool post hole and hence stopping the tool post from being inserted. Fortunately, I'd thought of that beforehand: what it needs is a spring (if you go back to the cross section animation at the start of this post, you'll see a convenient gap has been left for a spring to sit in).

A few years ago, I made a spring calculator for calculating the right arbor size for making a custom spring out of piano wire. Despite having made that calculator, I've never actually made a spring before: I always intended to but never really had a need for a custom spring. This seemed the perfect opportunity.

The process is very simple. You set up the calculator for the diameter of piano wire you have, pick a target diameter and other parameters that matter to you (e.g. pitch, length) and it tells you the arbor size on which to wind your spring. The arbor is a simple bit of steel with a hole drilled through the end:

The wire gets fed through something clamped in the tool post (I used a bit of plastic with a hole drilled through) and through the cross-hole:

After turning the spindle a couple of times by hand to make the end coils, you engage the lead screw half-nuts (with the leadscrew set up for the desired pitch) and then keep turning the spindle by hand. Once you've got the length you want, you disengage the lead screw half-nuts and do a couple more turns for the other end:

After trimming off the excess with some heavy duty side cutters, I slid it onto the brass bit and it was a perfect fit (so the calculator seems to have got the arbor size spot on):

After assembling it again, I put the tool post clamp block in the bench vice and tried it out. If you look into the hole in the first half of this short video, you can see the brass clamp moving in (under the cam force) and out (under the spring force):

The last thing to do was drill and tap an extra hole (located with a transfer punch after tightening the other two screws) in the banjo:

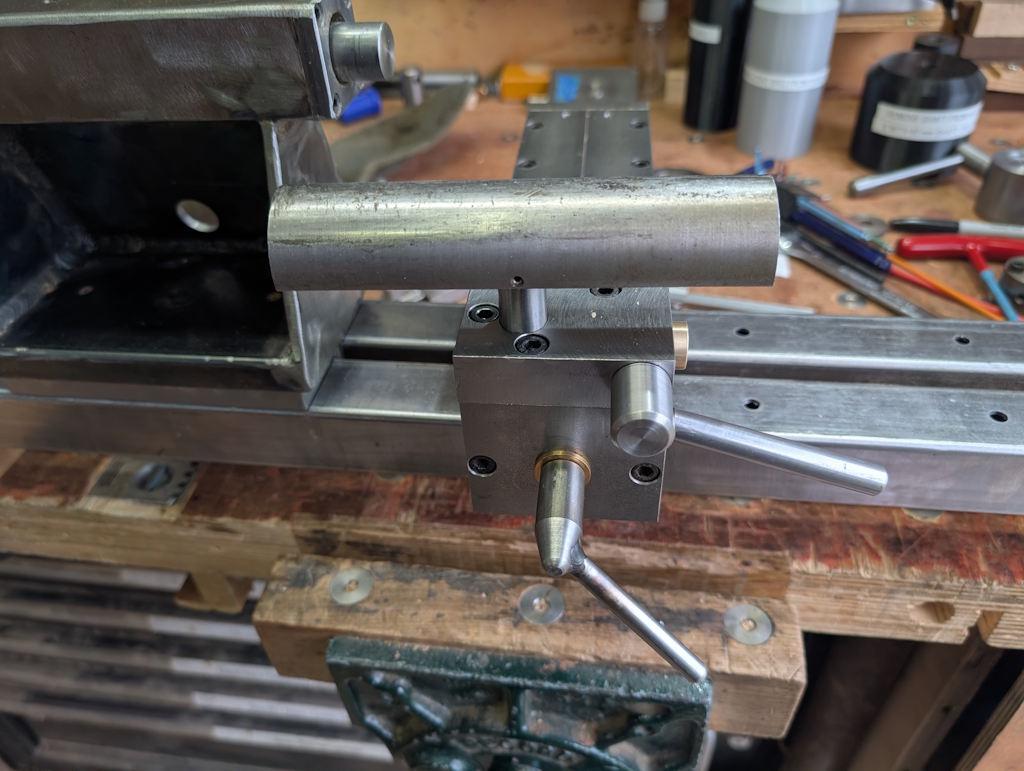

Complete:

I may shorten the brass clamp (so it doesn't stick out the side as far) at some point, but I'm going to leave it as-is for now. It's not doing any harm as far as I can see and it'll give me something to grab onto if I ever need to for some currently unforeseeable reason. I'd also like to round off a few sharp corners at some point (although I can't got that far as there are a lot of screw head counterbores that are very close to the edge).

Page 54 of 55

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page