Woodturning Lathe Build Process

Page 56 of 56

Posted 2nd January 2026

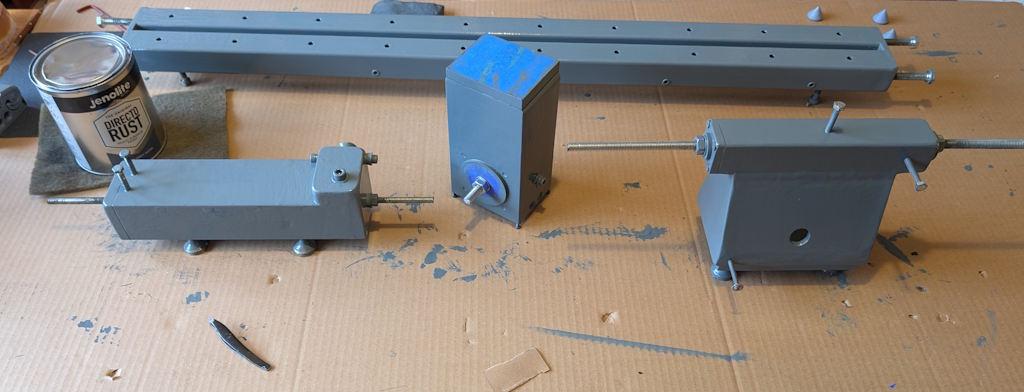

Over the last couple of days I've been painting the lathe (it only took me two years!)

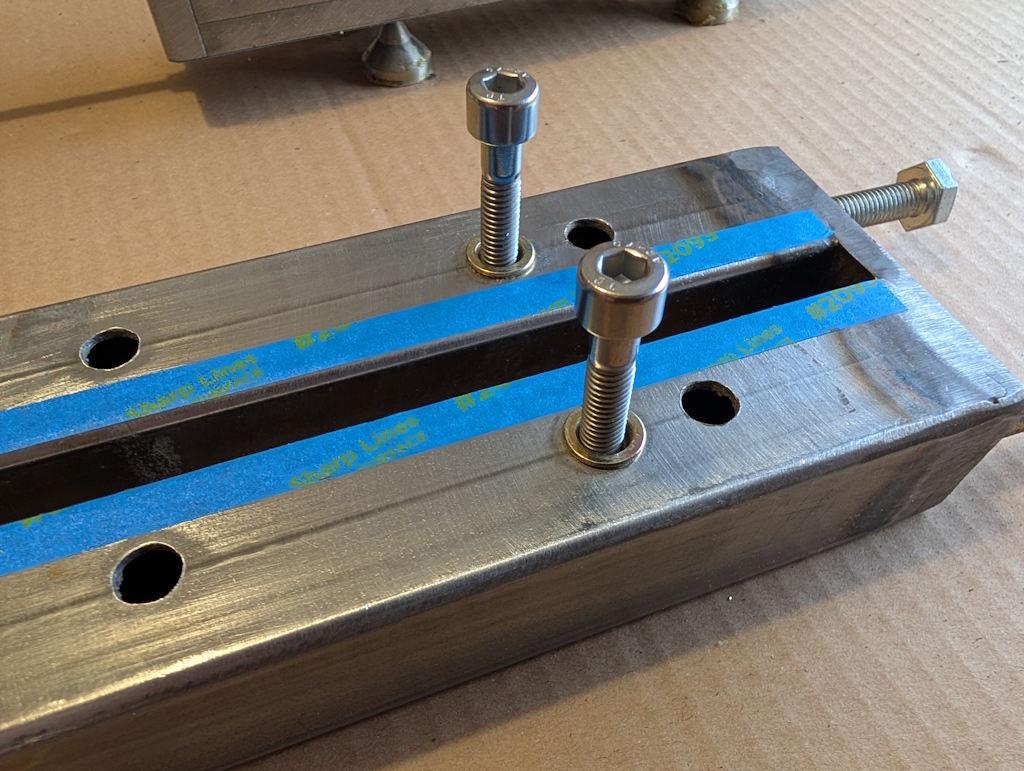

I started by applying some masking tape anywhere that was a running metal-on-metal surface. For the welded box section frame, that's just a narrow strip down the middle of the bottom where the locking washers will run:

The top surface was originally a running surface but since I've attached the extra steel plates on top (which won't get painted), it no longer has anything running along it.

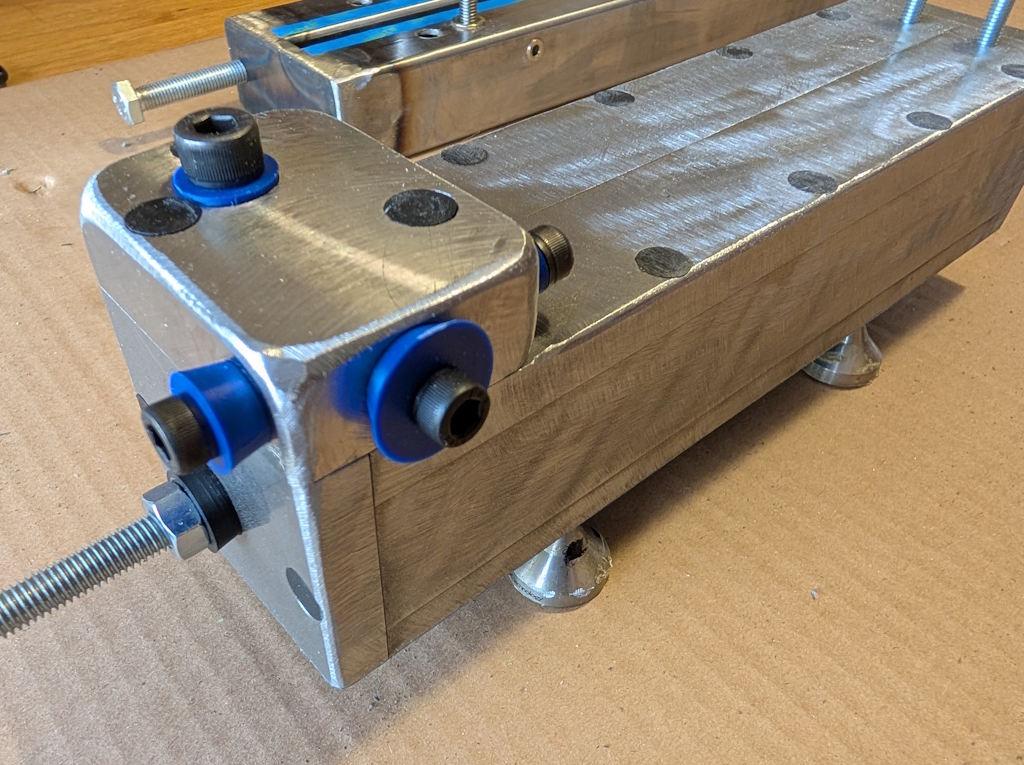

The tailstock and headstock got the significant holes filled in with some 3D-printed cones, most of the tapped holes filled with sacrificial screws and the bottom surfaces masked:

The banjo was the most complicated, with little black plastic plugs that fit into the hex socket in the cap screws and cover them up, a pair of printed cones on some threaded rod for the banjo locking bar holes and a very complicated arrangement of four interlocking cones to fill the holes for the toolpost clamp mechanism:

Most of those black plastic screw covers will stay there semi-permanently, only coming out if I ever need to dismantle the banjo. The two on the rear cover (not visible in that photo, but equivalent to the one that's lowest down in the image above) will get removed (as the rear cover has to be removed to fit the locking mechanism).

Once everything was masked off, I applied some paint, using the same "Slate Grey Satin" Jenolite Directorust paint that I used on the control cabinet for my heat treatment oven as I had most of the tin left.

I applied two coats, then left it overnight, then sanded some areas a little with 180 grit wet-and-dry, then applied a couple more coats in the sanded areas. Now I'll leave it overnight again before seeing whether I can remove the masking tape and printed bungs without doing any damage!

In the meantime, I've also done a couple of other minor jobs. The first was to clean up the thick washers (that run on the bottom of the box section as mentioned above). When I originally made them (just trying to knock the lathe together as quick as possible), I faced one side and then parted off to length. The parted-off side was a bit shabby, so I put the washers back in the three-jaw chuck (with a 3D-printed spider) to clean up that face:

The last job I did today was to treat most of the unpainted steel parts with cold blue and then oiling them with some rust protection:

The one that's still in the blue solution refused to change colour for some reason. It had multiple cycles of cleaning (with acetone and with wet-and-dry paper followed by acetone) and multiple long soaks in the cold blue solution but it was having none of it. I can only assume it's a different grade of steel to the other parts (although it turned really nicely, implying EN1A like the rest). In the end I gave up and just applied the rust protection oil.

Page 56 of 56

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page