Woodturning Lathe Build Process

Page 57 of 57

Posted 4th January 2026

A few minor jobs have been ticked off the list today, along with the start of something bigger.

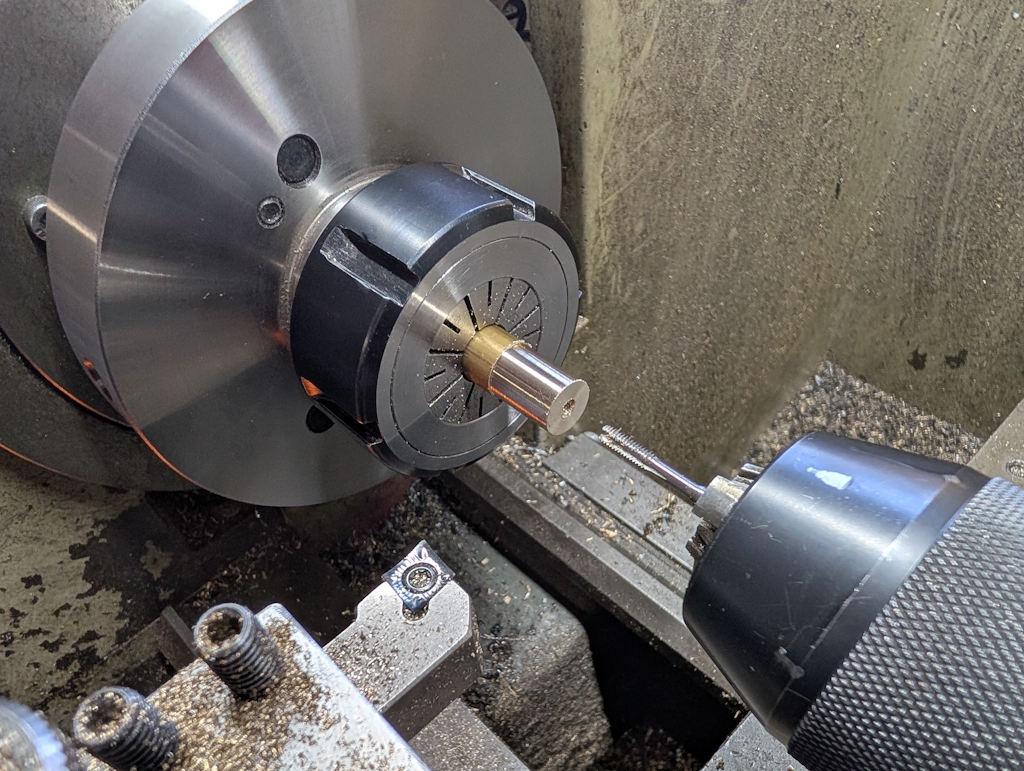

The first job I did was skim and face some brass bar and then drill and tap a blind M4 hole in the end:

That then got parted off, held in a collet and the other end rounded over, first with a chamfering tool and then with a file. A bit of threaded bar (actually an M4 cap screw with the head cut off) got fitted into the threaded bit with some Loctite 603 to hold it in place. It's a bit of an odd screw in that there's nothing to grip on the head in order to turn it:

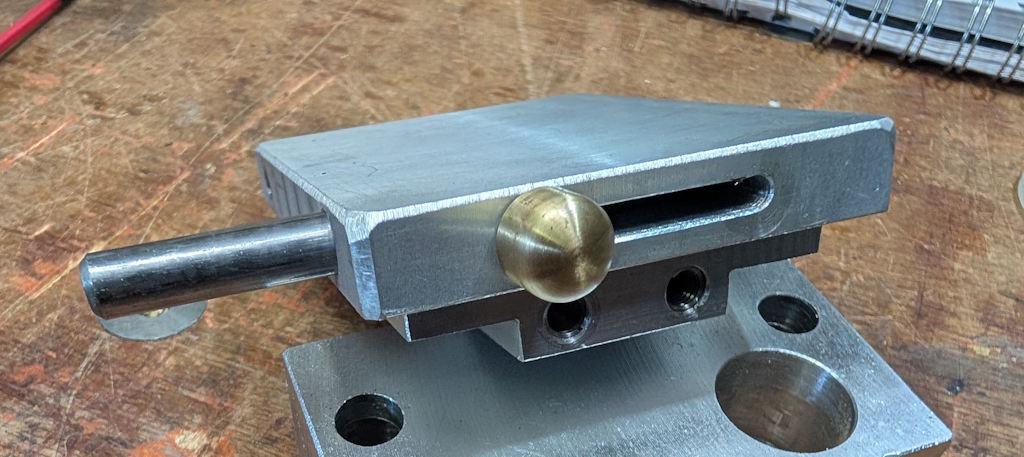

It gets screwed into the threaded cross-hole in that bit of 8 mm silver steel. I tightened it in place using an ER32 collet block to grip on the outside of the brass. All being well, it won't have to be undone. Those two bits get fixed together in the lid, thus:

The brass "knob" can be slid to the left to make the silver steel bar poke out the side of the lid:

That bar will (hopefully) engage with the holes in the dividing plate I made last week and is the other half of the dividing mechanism. I won't be able to find out whether I've made it (and the dividing plate) right until the headstock is fully assembled.

I'm thinking of 3D-printing a little cover to go over the slot (probably just magnetised in place) to stop sawdust getting in there. The design still needs a little thought to make it look relatively neat.

Another simple job was to make a couple of little top-hat washers out of 303 stainless steel:

Those will get glued (with Loctite 603 probably) into the holes in the front of the headstock (the one for the tommy bar and the one for the screw that will hold the cover for the first hole in place). The only reason for these washers is to stop the rotating cover from rubbing on the paint.

The last job I did today was to rough out the overall shape of yet another spindle (hopefully with the Morse taper cut properly this time) after the steel I had ordered arrived yesterday:

I doubt I'll manage to do any more on the spindle until Friday now, but all being well I'll get the spindle finished at the weekend and can start assembling the headstock (and then try out the dividing mechanism).

Page 57 of 57

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page