Woodturning Lathe Build Process

Page 60 of 60

Posted 10th January 2026

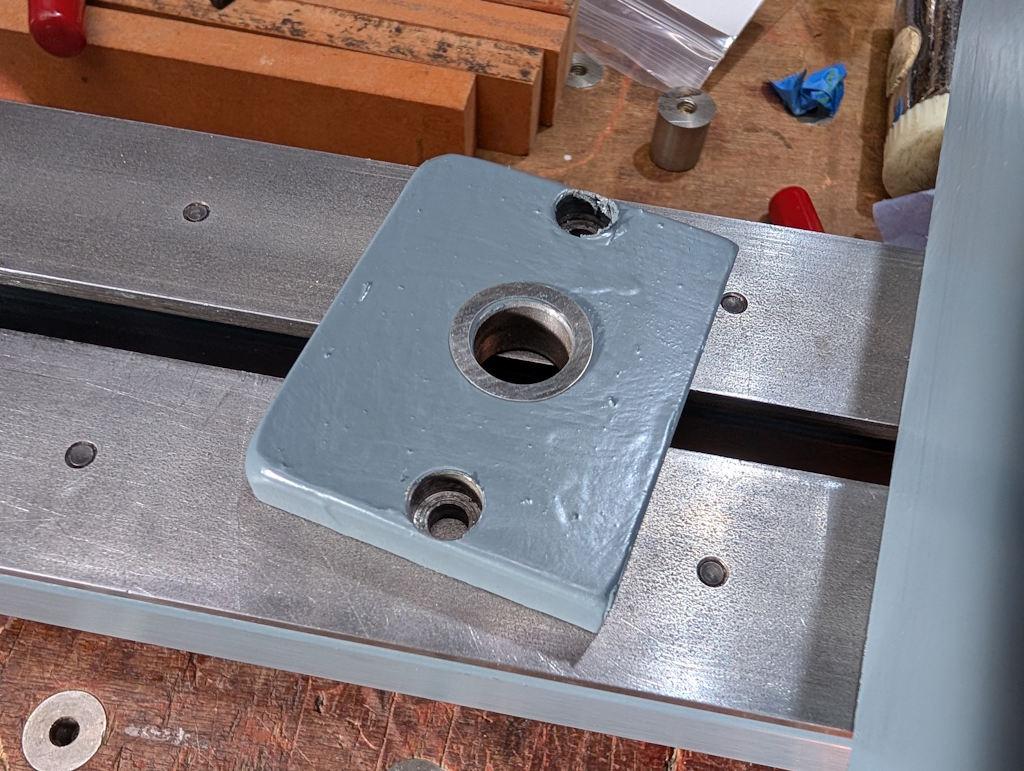

I spent the afternoon assembling more of the lathe. The first part of that was fitting the top plates that sit on the (now painted) box section bed). As before, I did that with the two plates clamped firmly onto a couple of 12 mm parallels. Those top plates form the reference for the tailstock alignment, so it's important they're parallel:

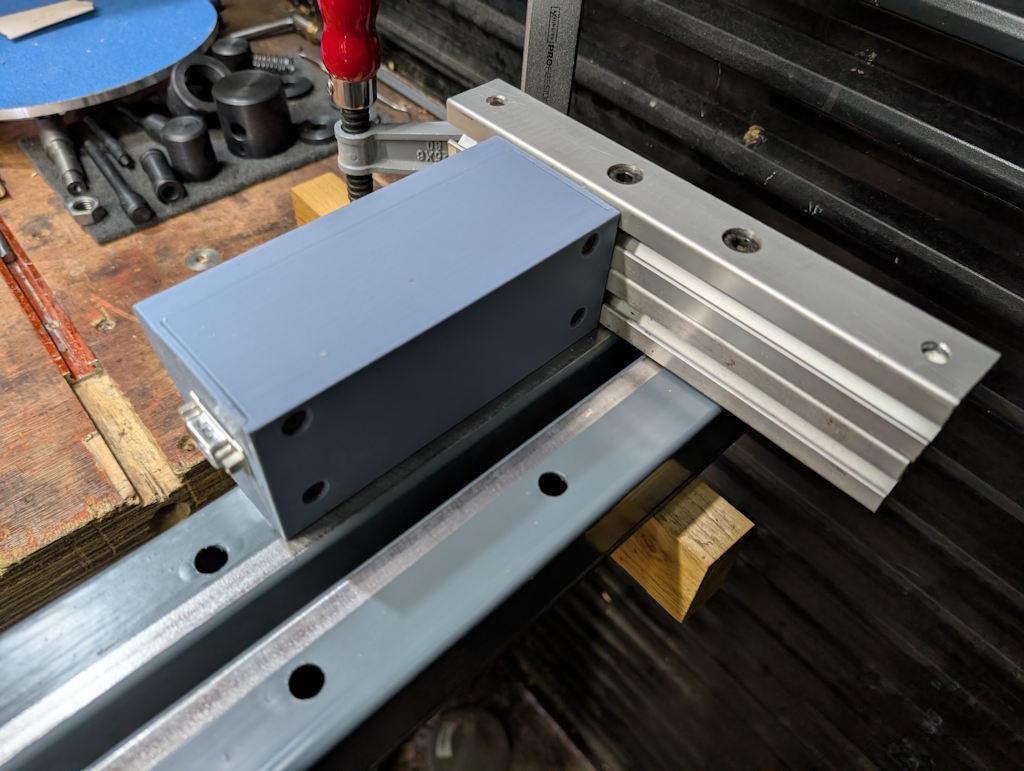

With that done, I could fit the aluminium extrusion that the bed sits on, along with the control switch box:

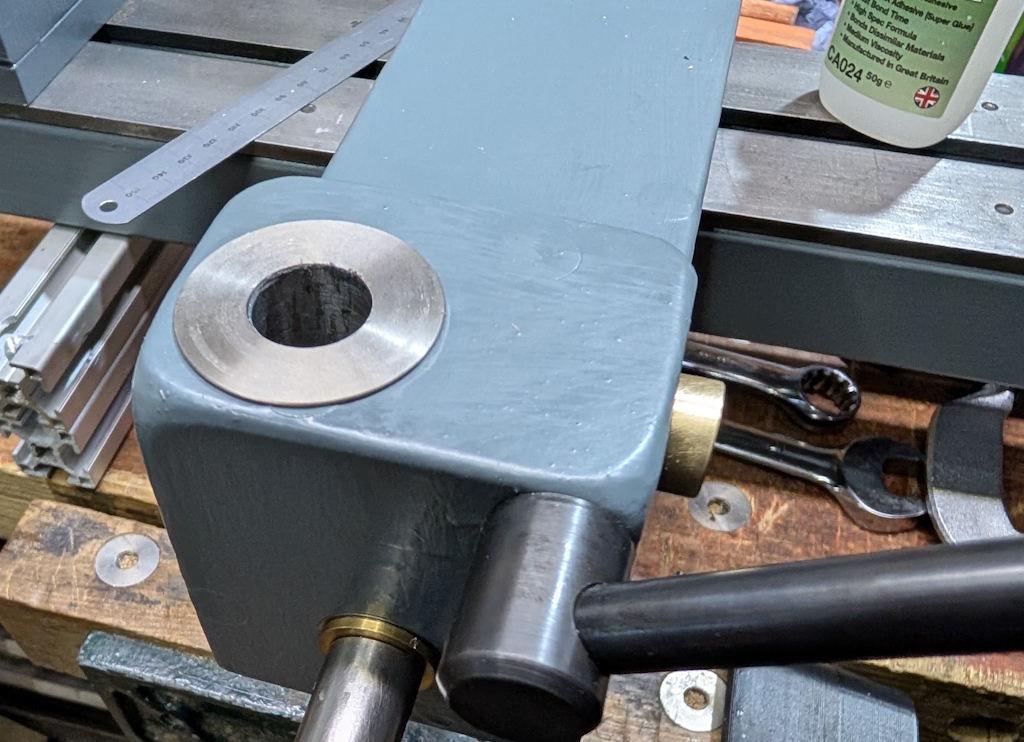

When I'd designed the banjo, I hadn't considered any impact of painting it. The brass washers that rotate in the end plates ran directly on the steel surface. Adding a normal washer isn't possible as there's a hole in the bottom of the end plates for an Allen key to access the locking grub screw. With a thick washer, that hole wouldn't line up with the grub screw location.

My simple but slightly lazy answer to this was to buy some stainless steel shim washers. I can make thin washers, but it's quite a tedious process (see later in this post). The 12 mm bore ones I could buy looked to be a good size so I went with that option. These ones are 0.25 mm thick (I also bought some 0.1 mm thick ones in case these didn't allow access for the Allen key). They're designed for adjusting the end float of bearings but they should do the job of protecting the paint:

I also wanted a thin washer to protect the paint on the top surface of the banjo. If I loosen the tool post clamp without holding the tool rest, the rest drops rapidly down onto the painted surface and I could imagine the painted surface suffering.

The thickness of the washer isn't critical here but I'd like it to be relatively thin. The thicker the washer, the more restriction I have on how low I can place the tool rest (although the new clamp block is 5 mm thinner than the old one, so anything less than a 5 mm washer will still be better than it was).

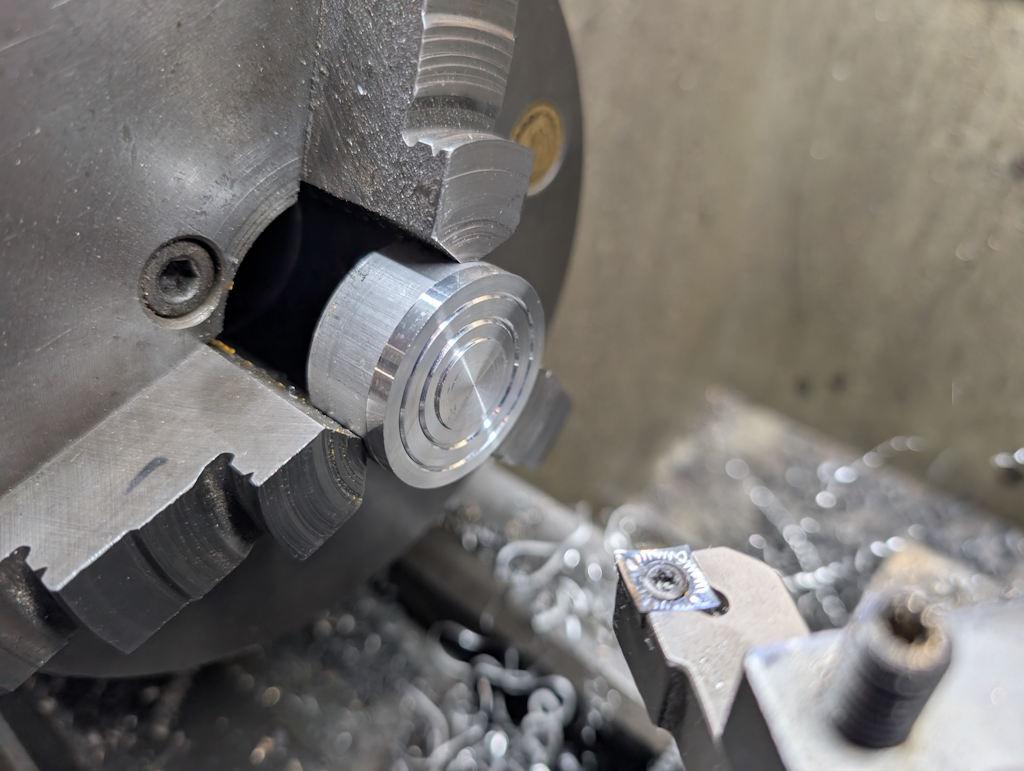

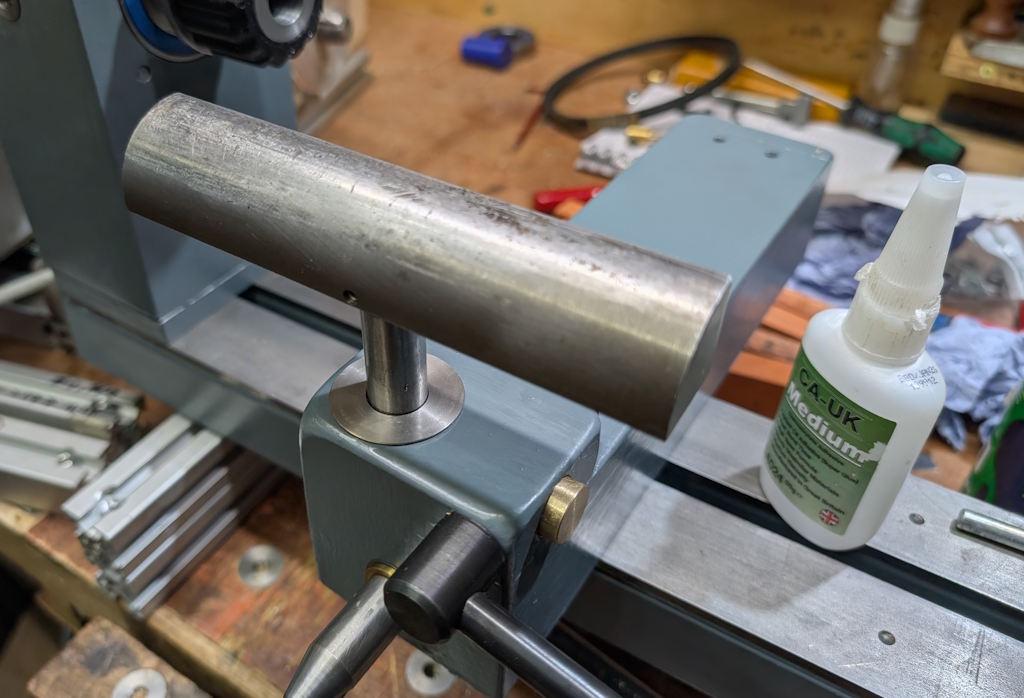

I couldn't find a source for a washer of the size I wanted for this job, so I made my own. It started life as a bit of 38 mm stainless steel bar, which I skimmed down to 36 mm, faced, bored out just over 16 mm and then parted off about 1 mm thick:

Parting off leaves a rough finish (I'm sure a better finish can be achieved but I tend to just touch up after parting off so I've never spent any time on practising):

I then put an off-cut of aluminium round bar in the chuck and shaped it thus:

It's got a shallow (0.5 mm) tenon of 16 mm diameter sticking out (to help centre the washer) and a couple of grooves cut into the face to help air / glue flow.

The washer then got superglued to the aluminium piece and, taking gentle cuts, I skimmed the face down until it was 0.6 mm thick:

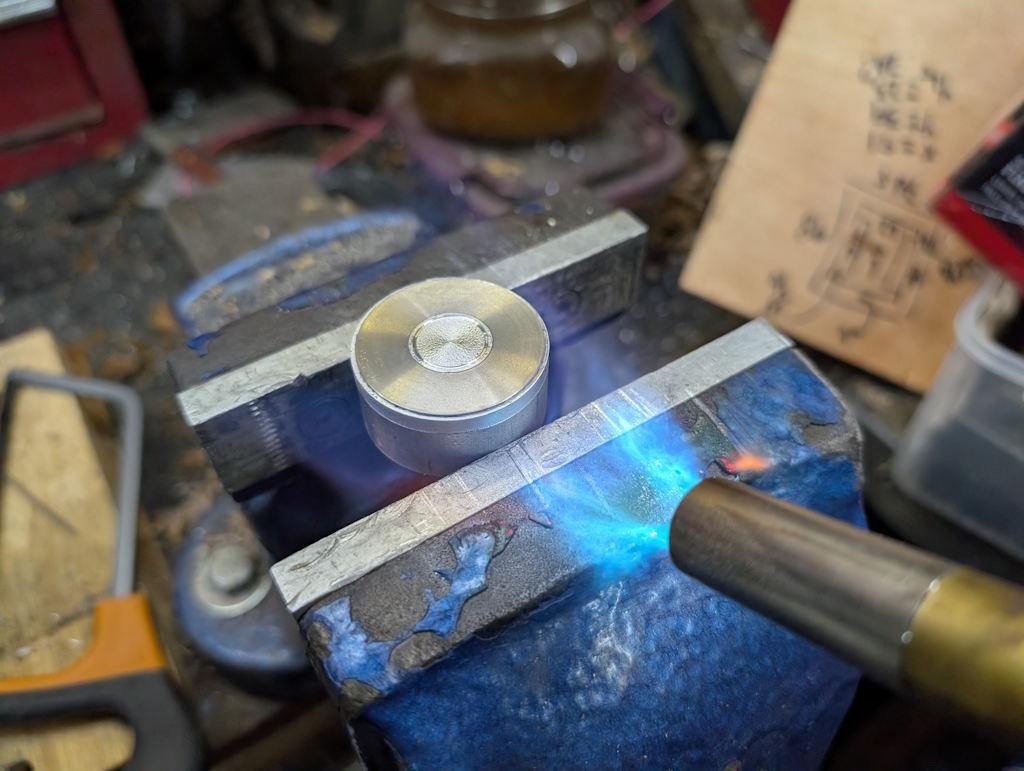

To remove the washer from the aluminium bit, heat is applied until the glue lets go:

After cleaning with acetone, it got some more superglue and then got clamped in place for a minute or so:

The end result:

It covers two of the screws that hold the tool post clamping block in place, so if I ever need to separate that from the rest of the banjo I'll have to remove this (along with the painted-over plastic plugs that already cover the three mounting screws). I can't think of a reason why I would need to dismantle it.

Here it is with a tool rest fitted:

Page 60 of 60

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page