Woodturning Lathe Build Process

Page 59 of 60

Posted 10th January 2026

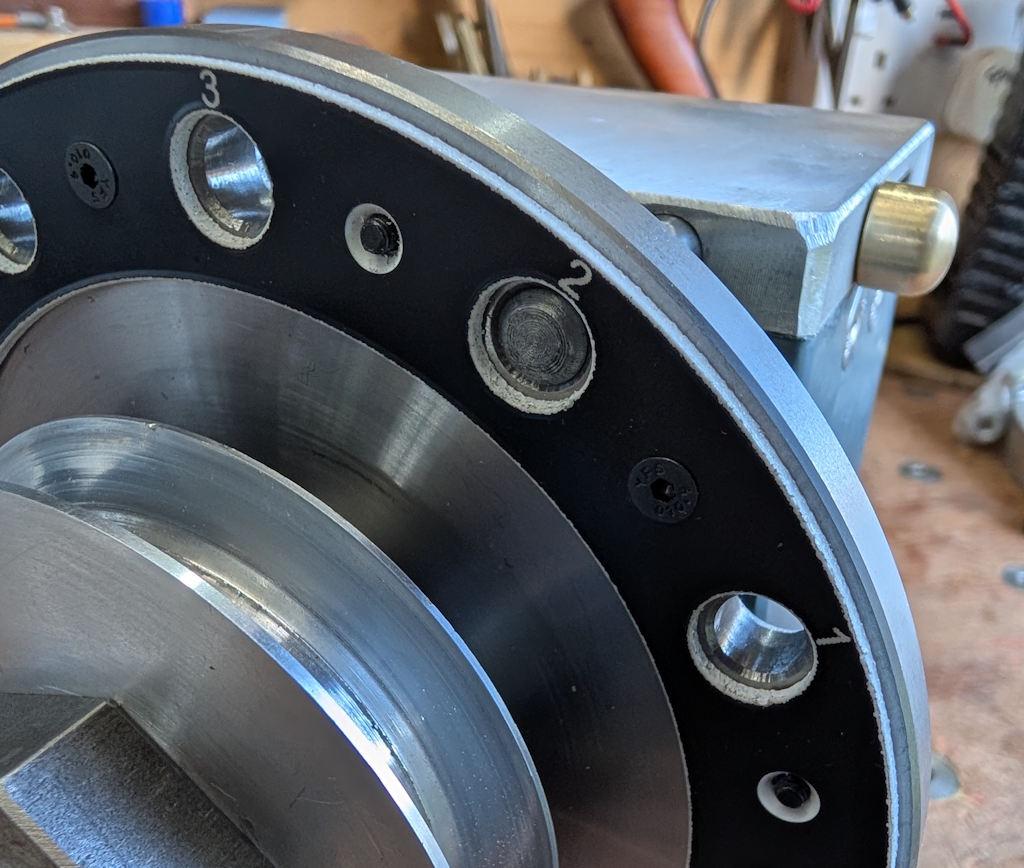

With the spindle complete, it was time to do a test assembly of the headstock. The first job was to glue the little stainless steel top hat washers into the tommy bar access holes:

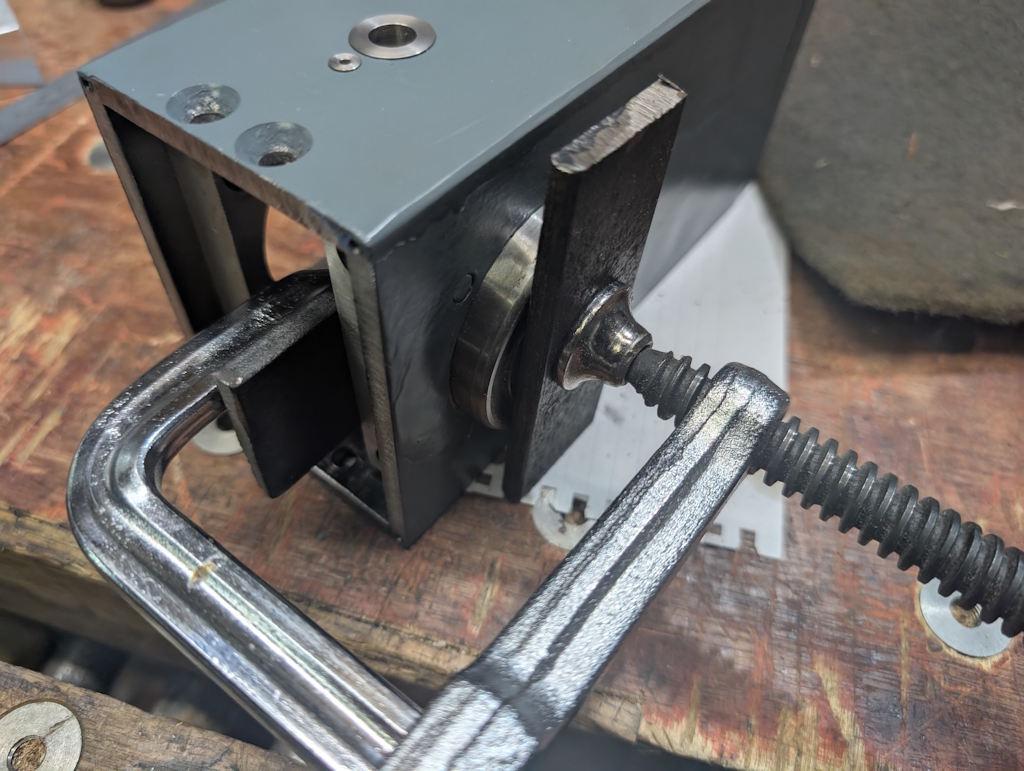

I could then squeeze the rear bearing in, using a couple of scraps of 6 mm steel flat bar and an F-clamp:

This was roughly the set-up for fitting the angular contact bearing onto the spindle:

I say "roughly" because I swapped the M10 threaded rod for some M12 stuff before actually pulling the bearing home. Here it is fitted:

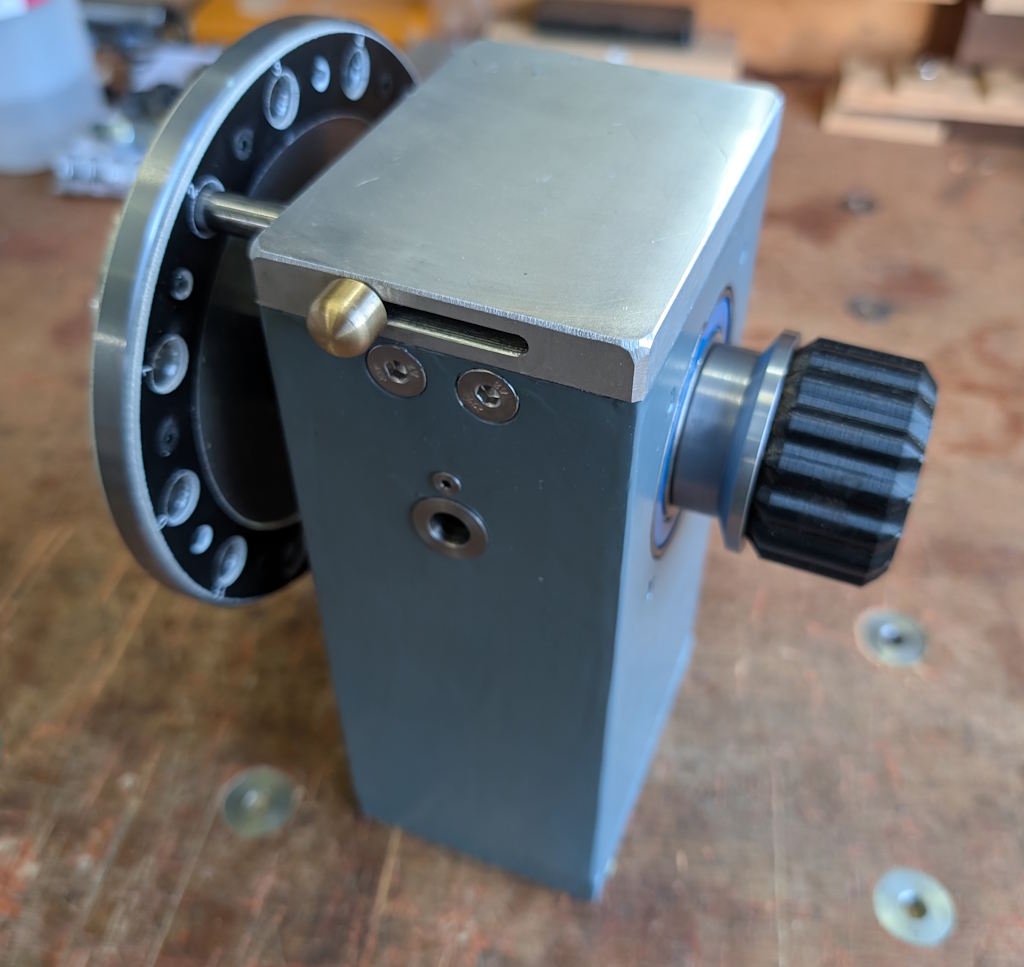

The spindle and angular contact bearing assembly then got pulled into the headstock (which already has the rear bearing fitted):

I'm very pleased to say that it looks like I got the hole for the dividing bar in the right place:

The locking bar length is just right as well (although that would have been very easy to fix if not):

I still need to make the cover for the tommy bar hole and fit a couple of 3D-printed bits (the chuck key holder at the back and the slot cover at the front), but otherwise that's the headstock finished.

Page 59 of 60

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page