Woodturning Lathe Build Process

Page 62 of 62

Posted 11th January 2026

This afternoon I thought I'd have a go at the table for the sanding disc. I started with the big bit of 10 mm thick aluminium plate that I found in a skip and marked a seemingly appropriately sized section out with a pencil then used a jigsaw to cut it out:

That's the thickest metal I've ever tried to cut with a jigsaw (the depth of cut on my metal-cutting bandsaw wouldn't have been sufficient). It and the (Makita B-23) blade seemed to make fairly light work of it so I was quite impressed. It was fairly slow, but it was steady and the blade was cool at the end of the cut. The last cut was done with the plate held to the bench at an angle to make sure both the table and the off-cut were supported:

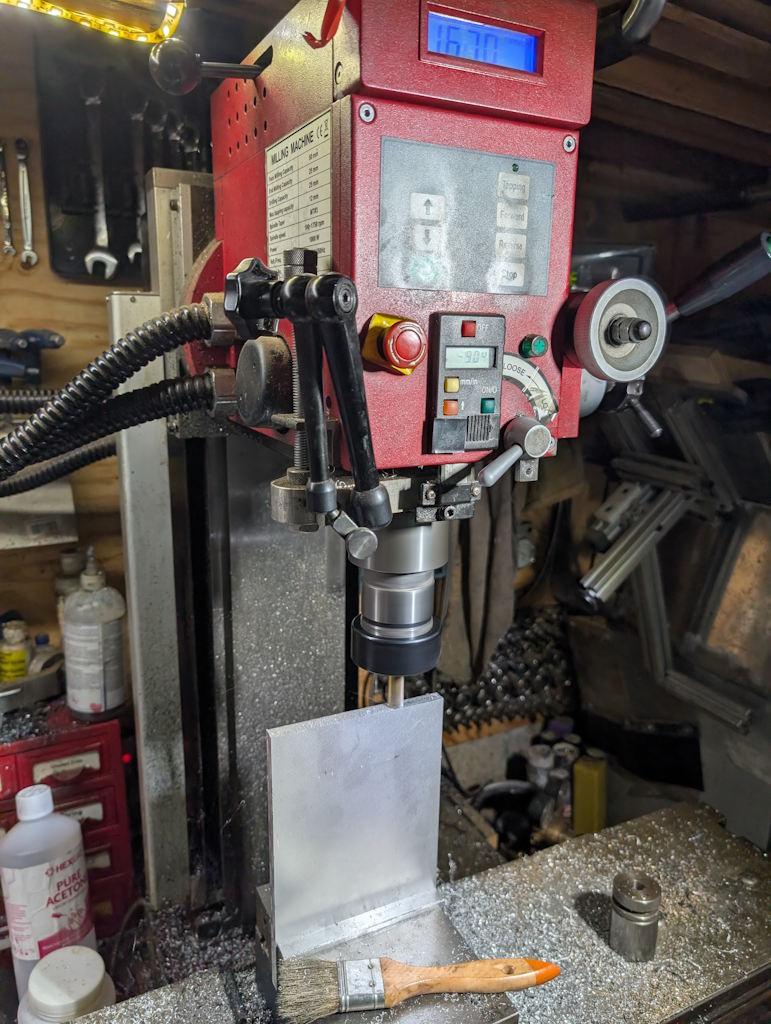

I probably could have left it with the jigsaw-cut edges, but I decided to clean them up with the mill. The long edge was straightforward:

For the short edge, I'd usually do that sort of thing with the part held horizontally and the side of an end mill travelling across the part. However, this part is too wide for the "Y" axis travel of my milling machine so I did it with the part standing upright. There was just enough clearance (although I could have used a shorter type of tool holder):

A very simple base was turned from a bit of 35 mm EN1A. It's got a short section reduced to 16 mm (to match the tool post diameter) and three M6 holes tapped in the opposite end:

Three matching countersunk holes were drilled in the table and the two bits could then be screwed together and fitted:

At the moment, I've got it set so that when the post is resting on the top of the banjo the top of the table is at centre height. It looks a bit high to me and, having now looked at a few commercial disc sanders, they seem to be set a bit below centre height.

It'll be a simple enough job to extend the 16 mm section of the base shaft (and hence lower the table) once I've decided how far to go.

Page 62 of 62

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page