Woodturning Lathe Build Process

Page 61 of 62

Posted 11th January 2026

A minor machining job was done today. As the spindle is a little longer than the old one, I needed to replace the two pieces of aluminium extrusion that connects the lathe to the motor assembly. That was a fairly simple job, just a case of milling two bits of extrusion to the same length and then drilling (with an end mill) an 11 mm hole near each end for the clamping thing:

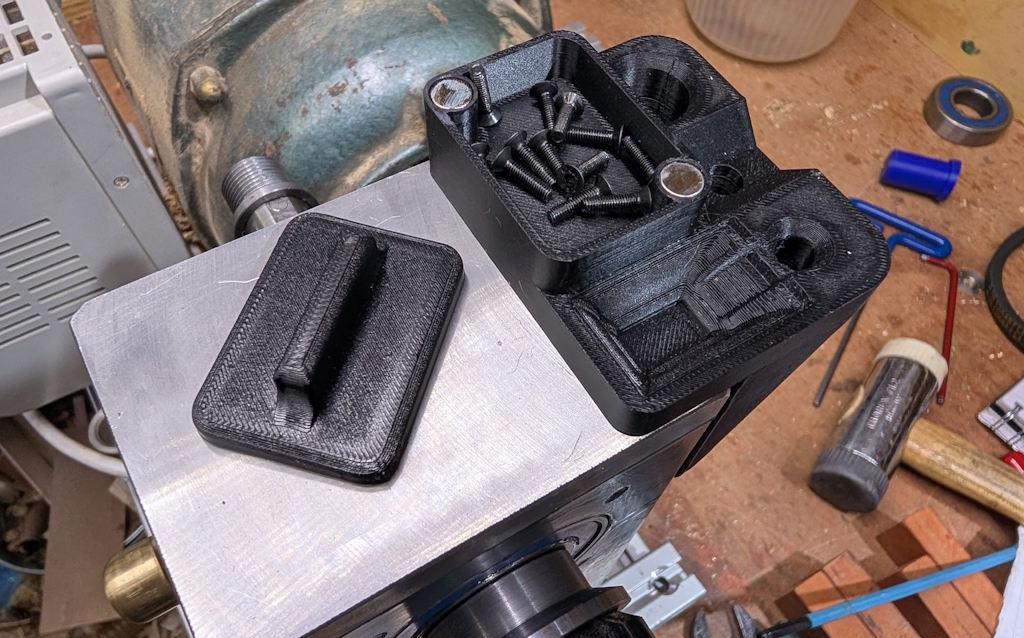

Most of the rest of what I've been doing today has been fitting 3D printed bits and bobs that have been made over the last week. The first one is a new chuck key holder. The old one was held in place with magnets and would occasionally come loose when removing the chuck key. The new one is screwed to the headstock. It holds the key for my lathe chucks, the key for the Jacobs drill chuck and a 4 mm T-handle Allen key which deals with most of the screws on the lathe (including the ones for the lathe chucks):

It also has a little pot for temporarily holding screws (e.g. the chuck screws when swapping jaws). The old one had this as an open top pot but, of course, it tended to fill up with sawdust so the new one has a magnetically-attached lid:

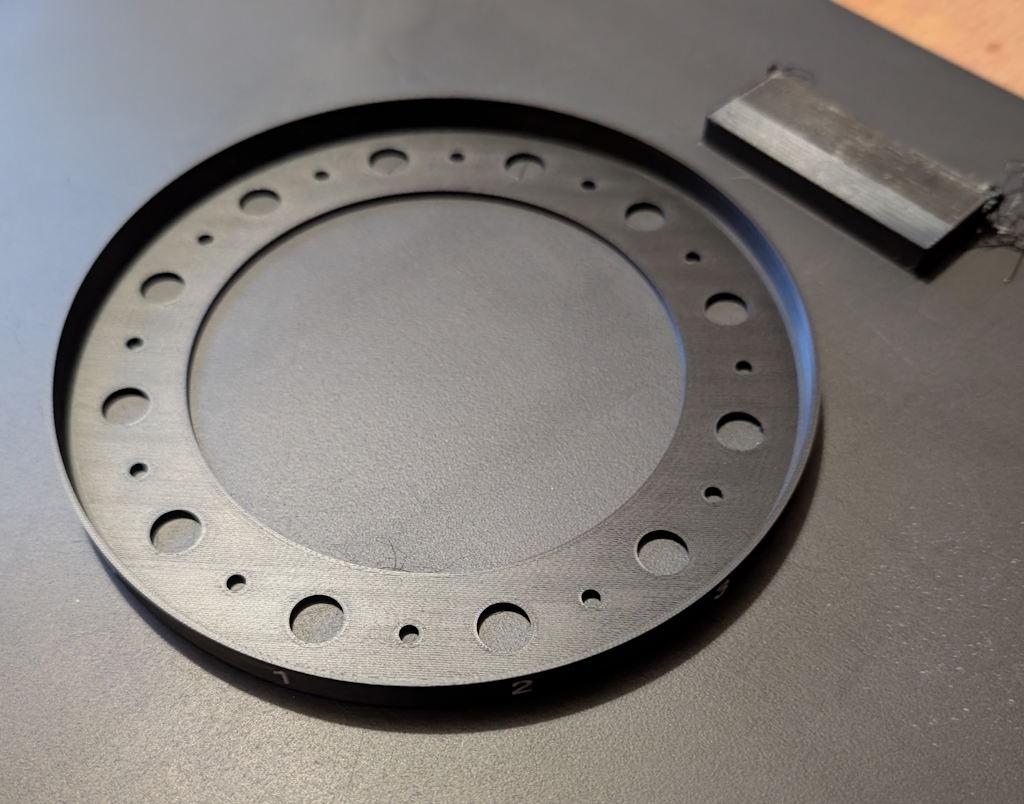

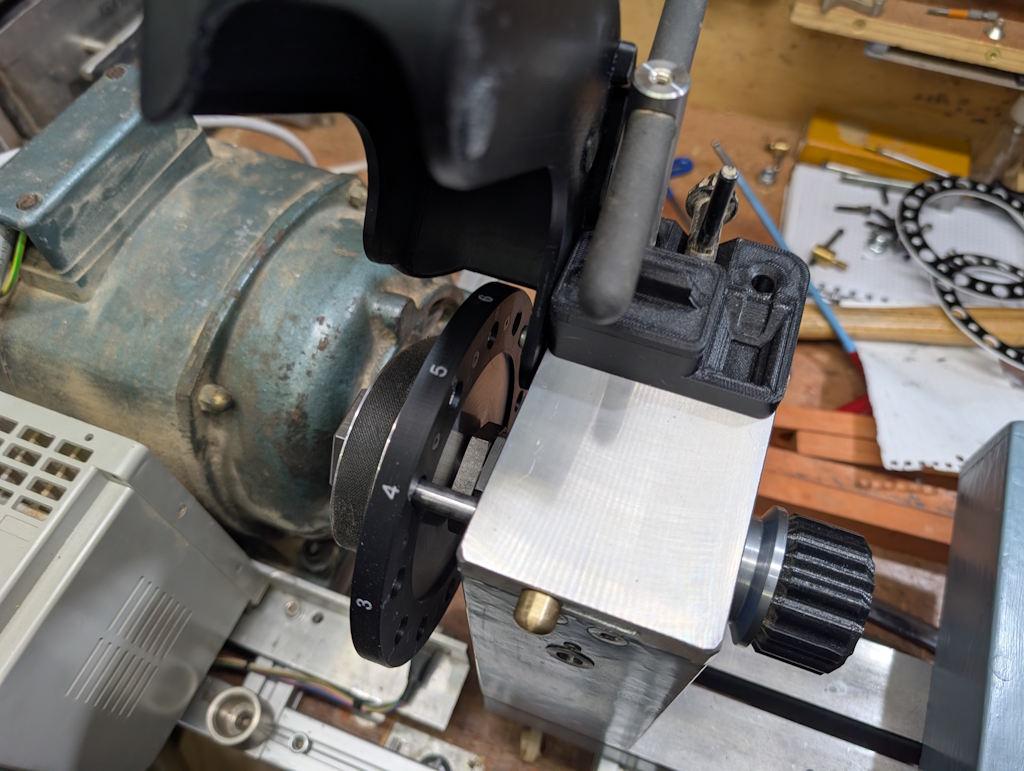

I also decided to replace the laser cut acrylic dividing wheel number discs with a single 3D-printed one. Here it is on the print bed:

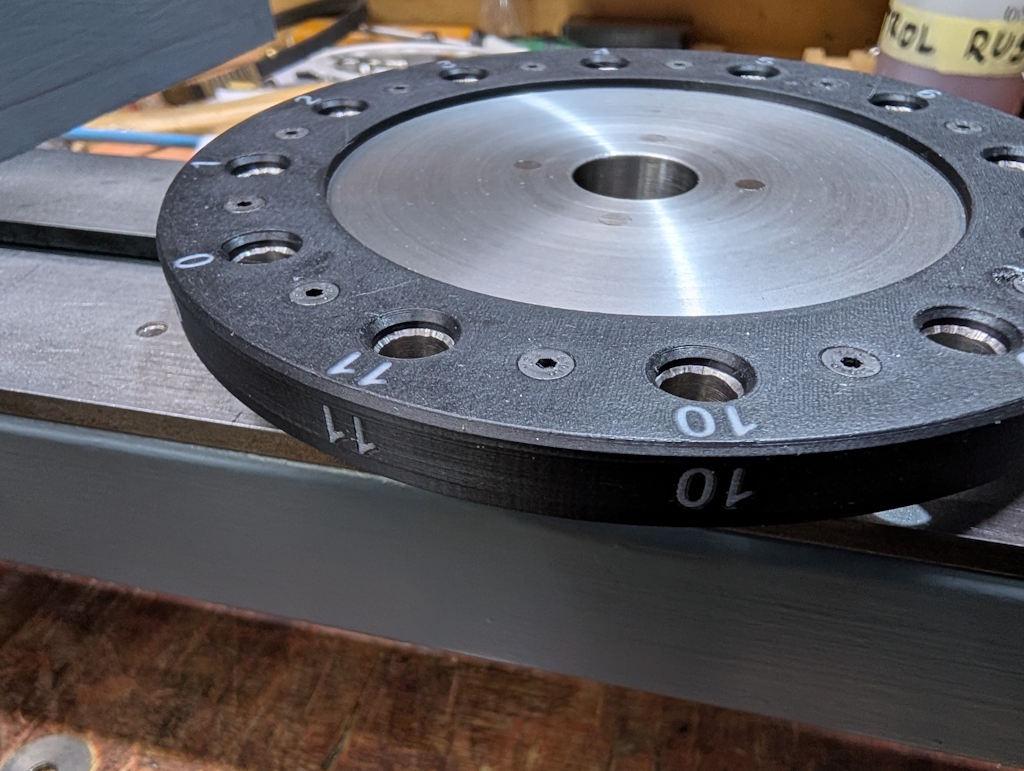

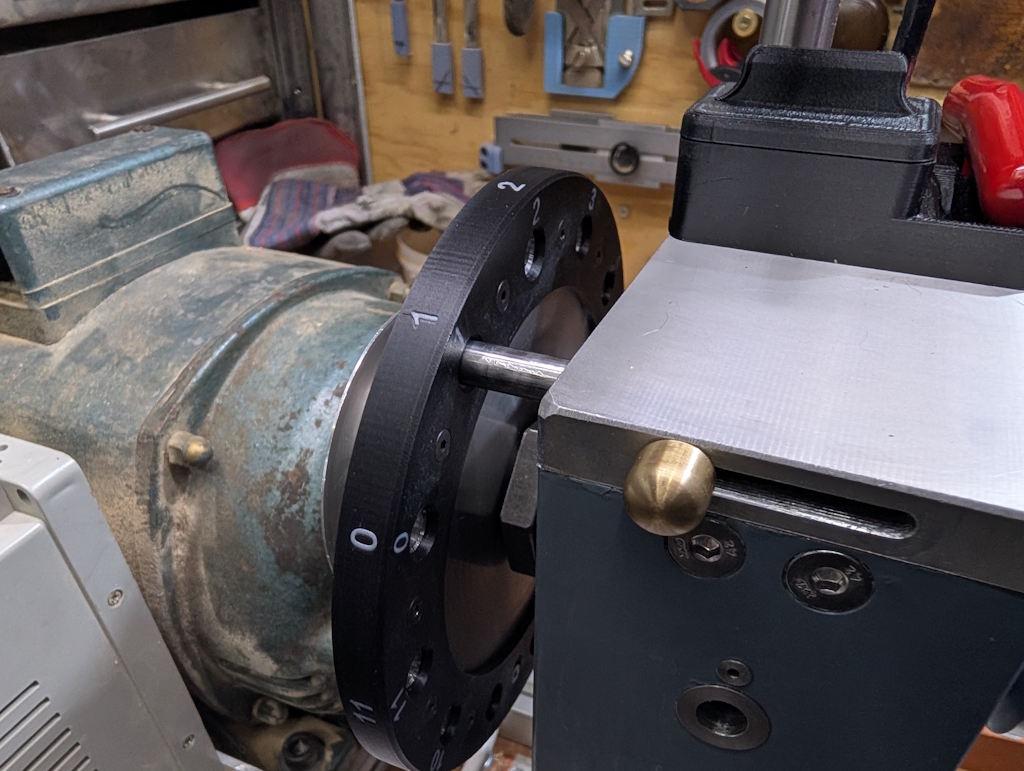

That gets held in place with M3×10 mm countersunk screws and wraps around the outside of the disc, giving numbers that I think will be easier to see:

Here it is fitted to the spindle:

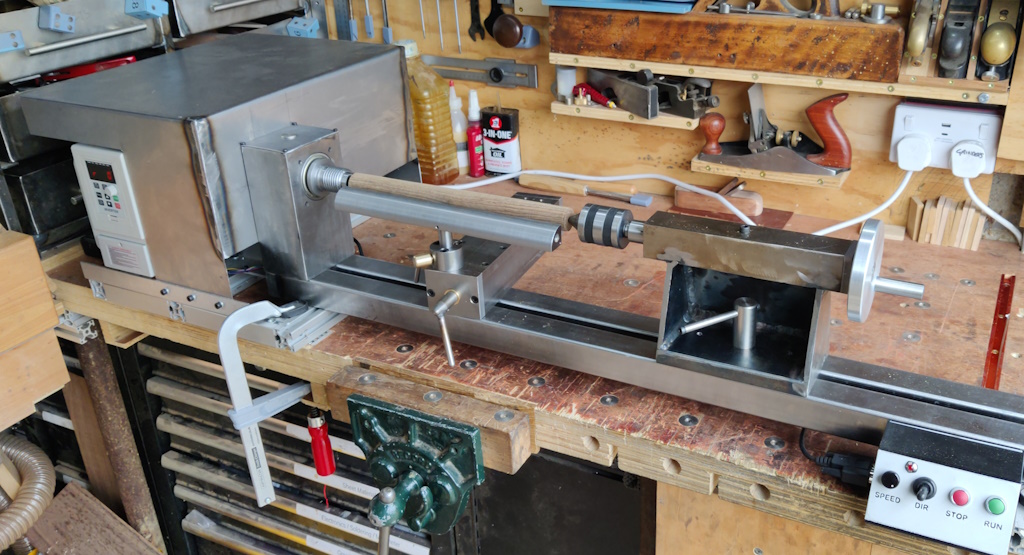

Those of you who have been following from the start might remember the belt guard I made when I first made the lathe. You can see it on the left of this old photo:

That belt guard obviously guarded the belt (and the motor, and the drive) and was very effective at keeping sawdust out the way, but it also got in the way a lot. In particular, it prevented me from putting a bar in the rear of the spindle to eject the drive centre. As a result, it didn't last long and ended up being cut up into bits and returned to the sheet metal drawer.

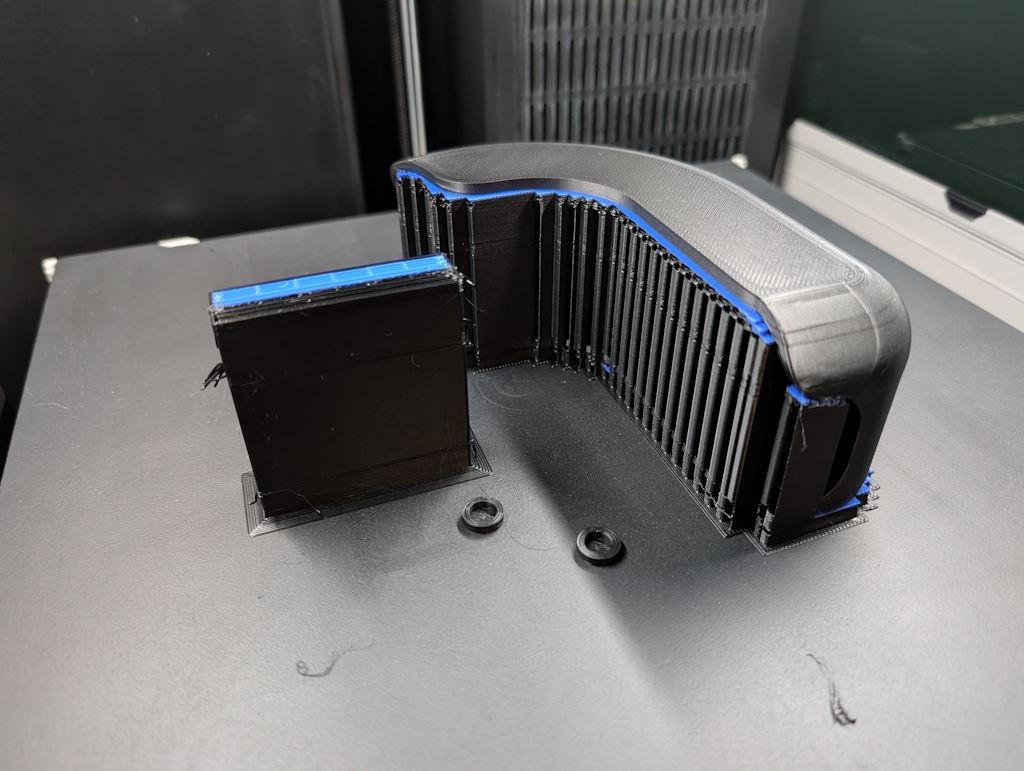

I went through quite a few designs in CAD for a new belt shield. The first one (second if you count the original guard) was similar to the original just a heck of a lot smaller. The second one tried to add a bit more curvature to the front surface and allow it to hinge. Finally, I realised that (in design number 3) I could just 3D-print it rather than restricting myself to shapes I could easily form from sheet metal. That gave me a lot more design freedom.

Of all the things I've ever printed, this is perhaps the least-suited to 3D-printing. Hardly any of it is actually on the bed of the printer (most of the lower surface sits on a support structure) and there's loads of supports internally:

The two little ring things are caps to cover some magnets that get glued into the belt guard.

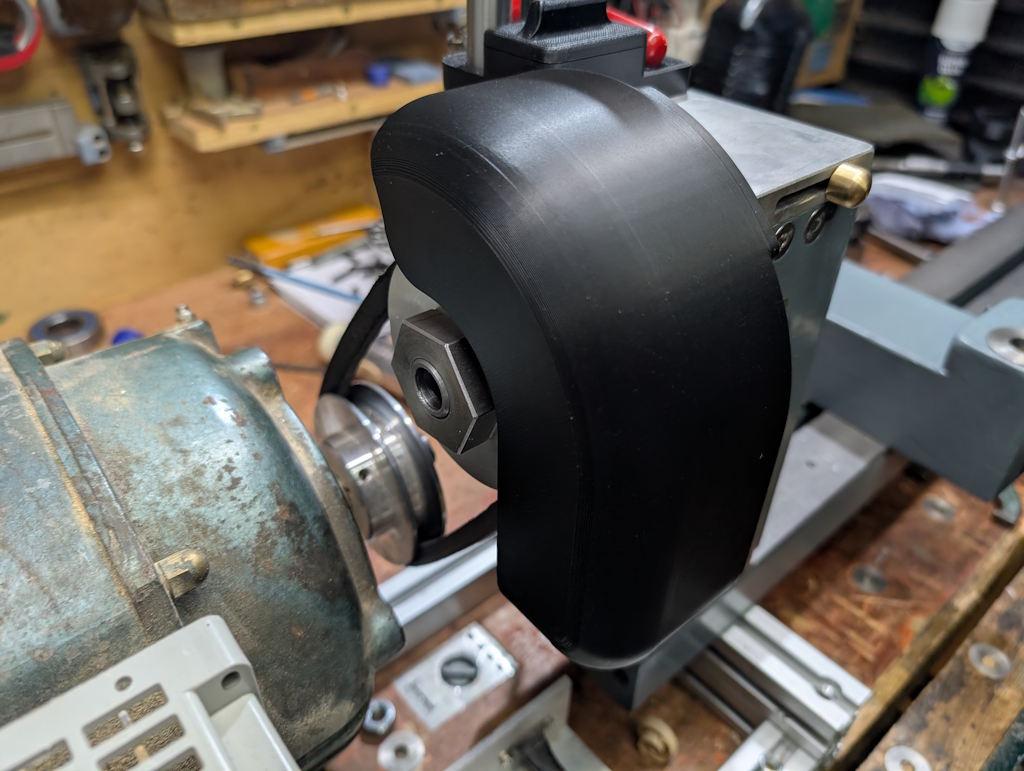

This is what it looks like mounted on the lathe. It covers the dividing wheel and the pulley but, as you can see in the following photo, still allows access to the rear of the spindle if required:

It's held in place rigidly with a single M5 cap screw that attaches to the lid of the headstock. Access to that screw is through one of the holes in the dividing wheel. There are also two 8 × 6 mm magnets that hold it to the headstock at the front to stop it rattling around.

It has the added benefit of covering up the end of the dividing head locking pin, so there's no chance of the locking pin sliding out while the lathe is running.

With the cap screw at the back loosened, it can be tilted up and stops (by hitting the chuck key holder) at this angle, allowing access for dividing (or fitting the belt when setting up the lathe):

Another quick 3D-print was this (magnetically attached) cover for the slot for the dividing pin, which will hopefully keep the sawdust out:

As you can see, I still haven't made the cover for the tommy bar hole (and there's a bit of stray plastic on that cover that I only noticed when I saw the photo - since removed).

You may remember that I made a "Lazy Susan" for my wood lathe tools:

When I'm turning, I tend to find that I often want to put a tool down for a few seconds just to (say) measure something. I tend to do that by plonking it on the bench (as it's quicker than spinning the Lazy Susan and dropping it into its home), which is a bit awkward (especially as I often end up with a lot of clutter on the bench that I'd rather keep away from the tool tip).

As an alternative, I 3D-printed a temporary tool holder, with six 8 × 3 mm magnets glued into it to hold it in place on the tailstock (this was right up at the limit of what I could fit on the bed of my printer):

The bottom end of that tool holder has a hole in it, which will hopefully allow sawdust to drop out the bottom.

Apart from the tommy bar hole cover, that's everything done on the lathe, so I thought I'd have a bit of a tidy up and take a couple of photos:

I'm really pleased with how the lathe is looking (it's still in that nice phase before any of the paint has chipped off!) and it does feel like the work I've done over the last few weeks has been a worthwhile improvement.

Hopefully I'll get that tommy bar hole cover finished next weekend and then I can really call it done.

Page 61 of 62

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page