Woodturning Lathe Build Process

Page 65 of 65

Posted 18th January 2026

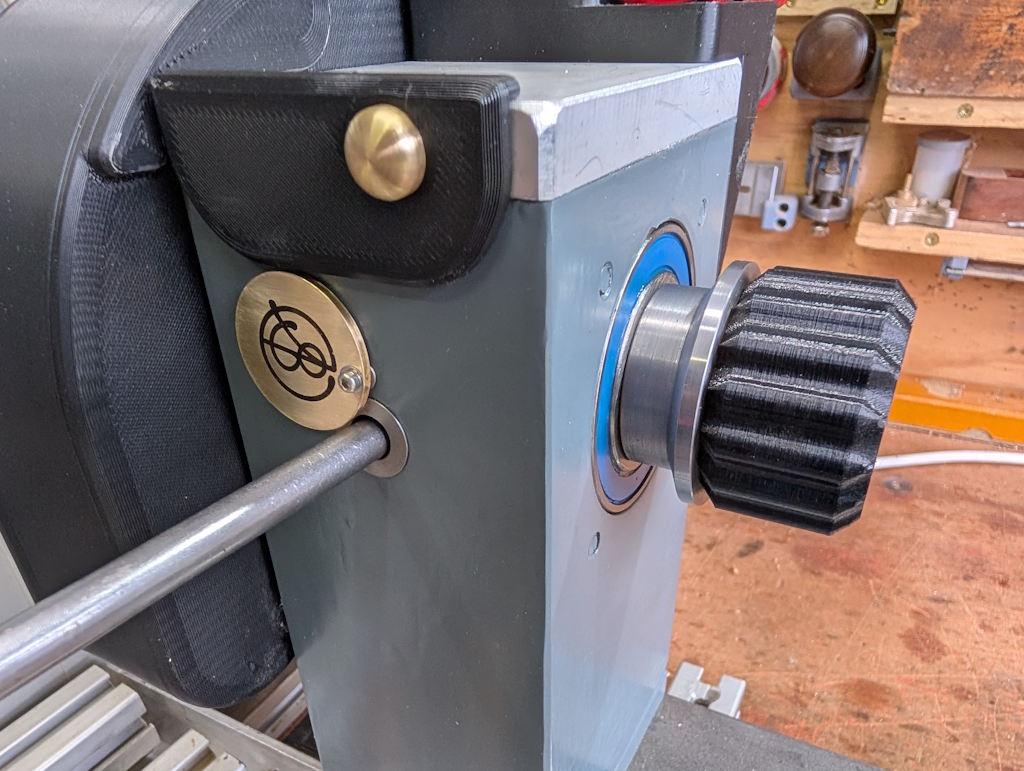

The last, relatively simple, job for the tommy bar hole cover was to fit it. I used an M2 × 16 mm cap screw, two washers and two nuts. I'd have preferred a nyloc nut, but I don't think you can get them for an M2 screw. Fitting was a little awkward just because of the tiny 4 mm nuts but it didn't take long.

I also replaced the 3D-printed slide cover with a plain one (that I'd printed at the same time). It seems a bit daft having the logo on there twice. I put the logo on the original slide cover for two reasons. The first reason was that I wanted to try printing the logo and seeing how it would look. However, the main reason was that I wasn't convinced I'd manage to make the brass/wax logo and wanted to have my logo on the lathe in the event that I gave up and used a plain metal disc.

Here's the disc swung out of the way allowing access to the hole:

Finally for this (possibly final?) round of lathe upgrades was a simple job: adding another mount for the Lazy Susan at the tail end of the bed. There's one already at the headstock end but sometimes the tools get in the way when, e.g. shaping the outside of a bowl, so it's nice to be able to move it to the back end. At the moment I just drop it into one of the dog holes in the bench, but I can see the twisting force wearing the dog hole out so I thought I'd add a steel mount to the lathe structure:

With that, the lathe is as complete as it's going to be. I took some photos because it seemed like a good idea. Note that the photos were taken before I fitted the tail end mount for the Lazy Susan: after fitting that the heavens opened and the sky went really dark and I didn't think I'd get a very good photo!

Page 65 of 65

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page