Dividing / Back-Stop / Spindle-Crank

This little tool-kit serves a few functions:

- Dividing on the lathe

- A lathe back-stop

- A lathe spindle-crank

Spindle Clamp

The common part of the tool-kit is a method of clamping into the inside diameter of the rear of the spindle. This is achieved with these two components:

The part on the left is a mild steel nut made from 20 mm bar with an M10 thread tapped all the way through and a taper turned on one end. The part on the right is made from a 25 mm bar with the majority turned down to be a close sliding fit in the spindle (20 mm in the case of my lathe). It is bored with a very shallow taper and the end that is at the bottom of the picture has a 10 mm hole through. The slots were cut using a hacksaw (hence not looking very neat). By inserting the nut into the expanding sleeve and pulling the nut with some sort of threaded bar, the sleeve clamps onto the inside of the spindle and is locked in place.

This is the screw that is used for dividing or as a spindle-crank. It was turned on the lathe from a piece of 13 mm AF hex bar. The part to the left of the remaining hex section is designed to fit the changewheels that come with the lathe. The hex section can be used with a 13 mm spanner to tighten the expanding sleeve into the lathe's spindle and then the changewheels can be used for dividing.

Dividing

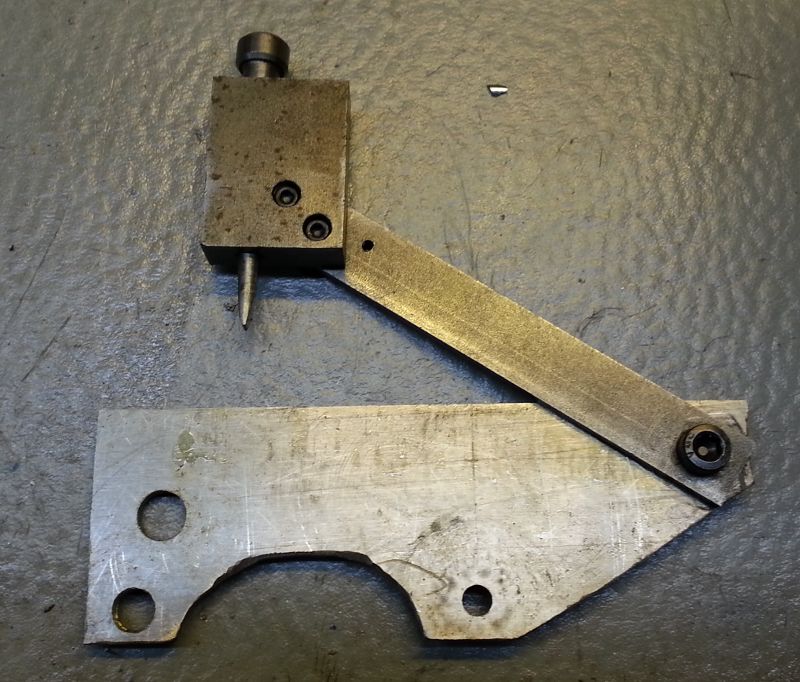

This is the indexer that is used with the changewheels in order to divide on the lathe.

It is mostly constructed from bits of scrap steel I had lying around and was mostly made with a hacksaw and the pillar drill. The component at the top has a shaped pin (the shape was made with a hand file) and a spring to push it into the changewheel in order to index around the teeth of the changewheel. The two holes at the bottom are used to mount it onto the back of the lathe's headstock (the left hand hole is slightly larger to accommodate for the fact that I drilled it in the wrong place).

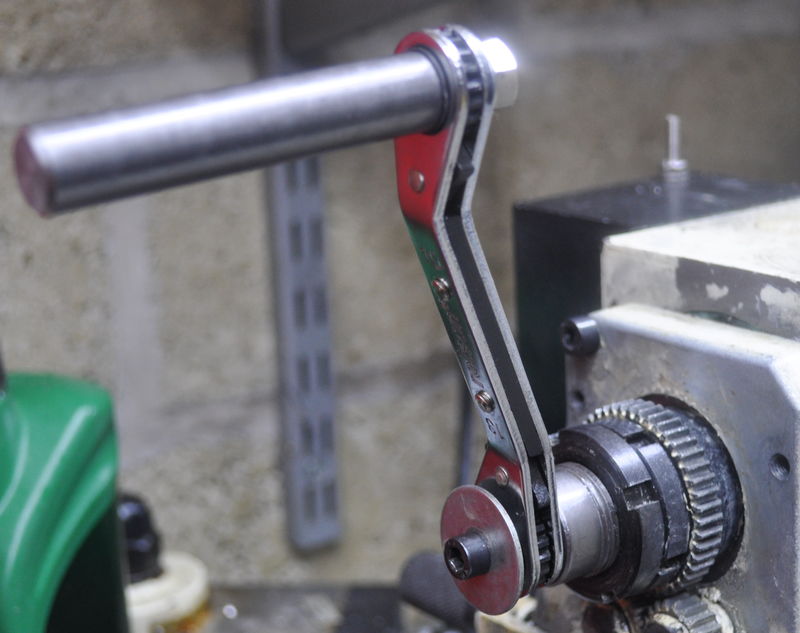

Spindle Crank

As an alternative to fitting the changewheel and indexer, this Rolson 10 mm × 13 mm Offset Ratchet Ring Spanner with a spinner handle I made for it can be used as a spindle crank.

Back Stop

Finally, the expanding sleeve can be used with some threaded rod and a nut to create a backstop for the lathe. The part on the right consists of a 19 mm aluminium block with a tapered end that is threaded M3. To the left of this is a 20 mm nylon sleeve that holds the assembly true to the spindle bore; this is held in place with an M10 nut. On the right, I can either fit a steel plug like the one shown (used as a backstop for a piece with a hole in the middle) or just have an M3 cap screw protruding for use with very small components held in the chuck.

The assembly is tightened into the spindle using the nut and washer shown on the left of the picture.

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.