Heat Treatment Oven Build Process

Page 17 of 35

Posted 3rd January 2025

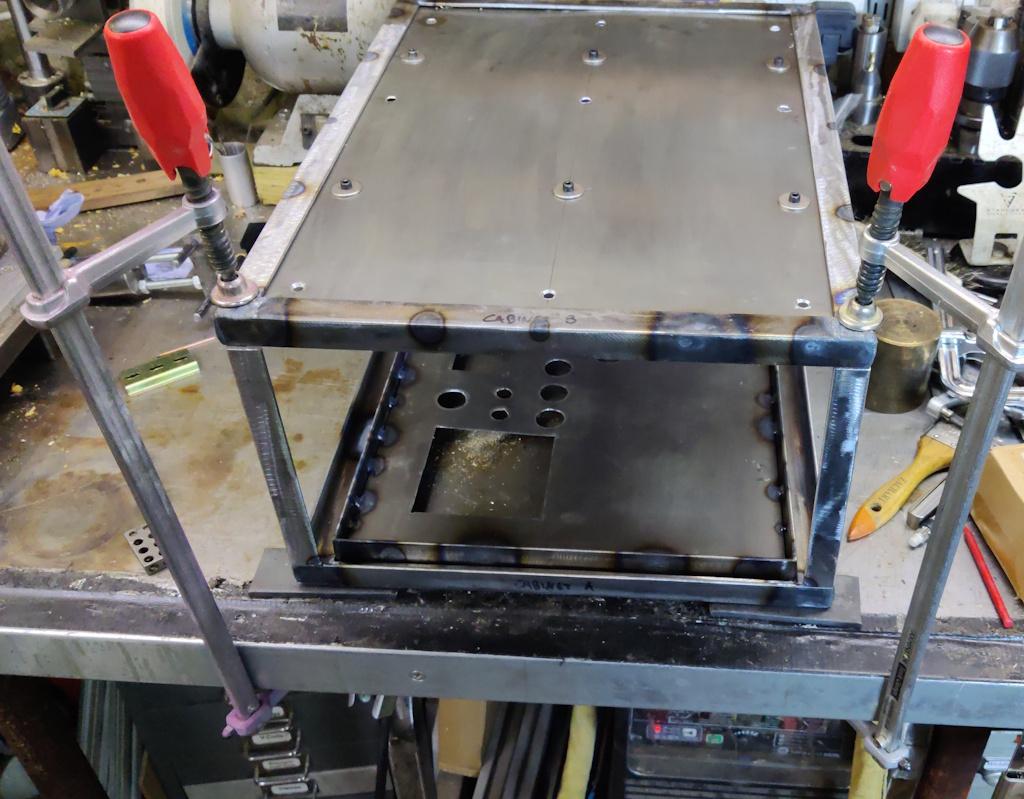

The first job this morning was welding the control cabinet frame together. I cut four 180 mm lengths of angle iron and tacked them to the door frame. I then clamped the top frame on and tack welded that in place:

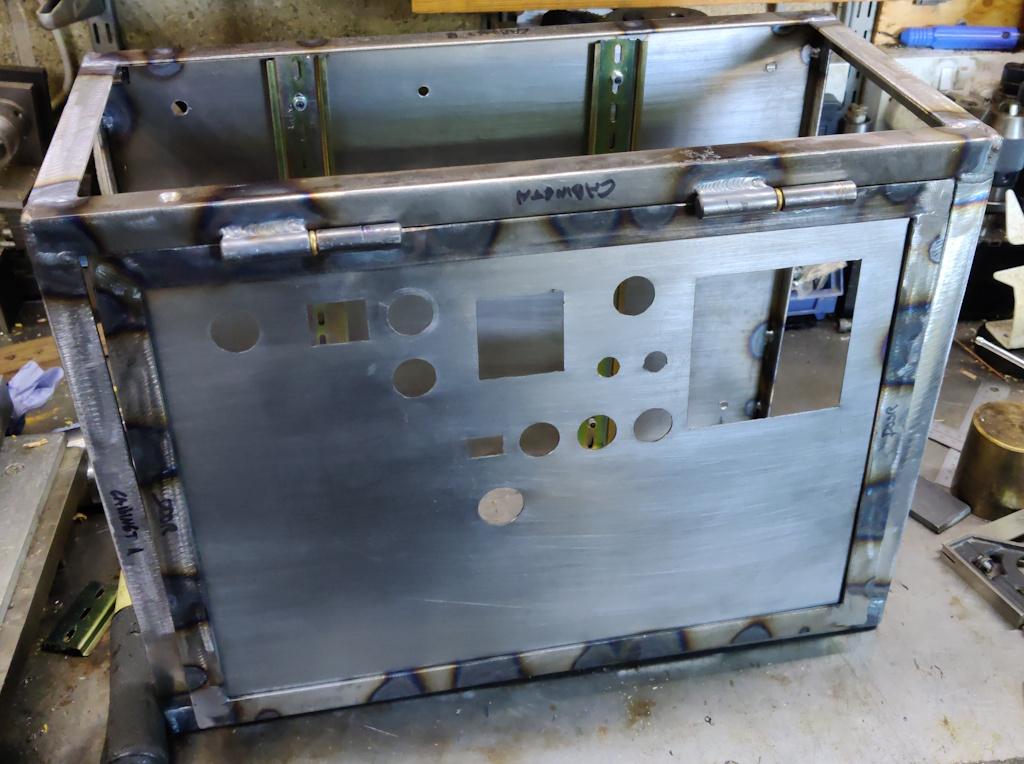

After checking how square it was (not entirely, but close enough: I rarely manage perfectly square welded constructions when there are this many joints involved), I could finish the various welds off. This was a lot more awkward than previous welds due to the size of the object. This orientation in particular involved standing up to weld, which isn't the end of the world, but is definitely more difficult than doing it seated:

This orientation wasn't too bad:

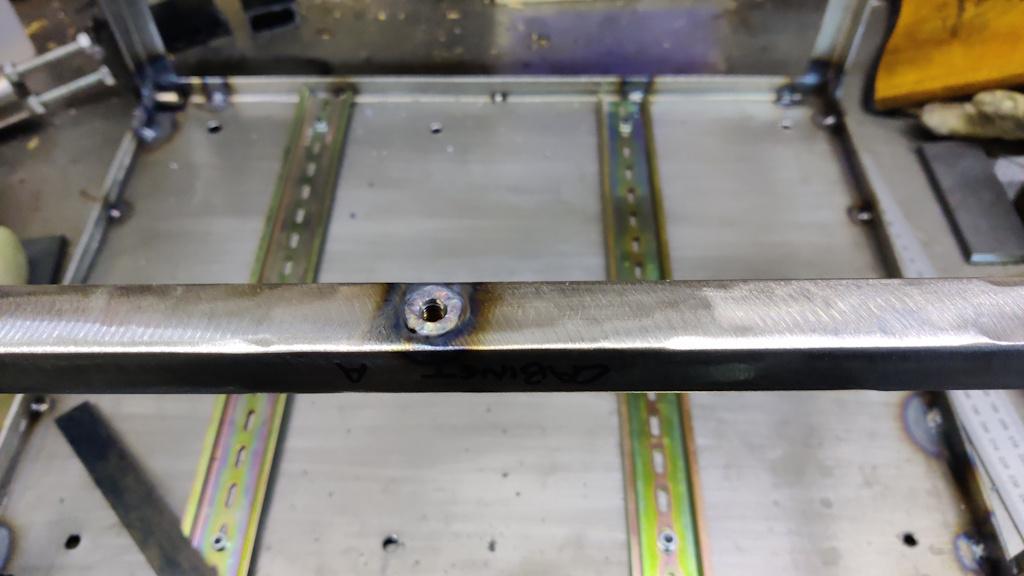

While I had the gas on and the welder powered, I drilled a 10 mm hole in the cabinet frame and set an M6 weld nut into the hole:

That'll be used for the door latch.

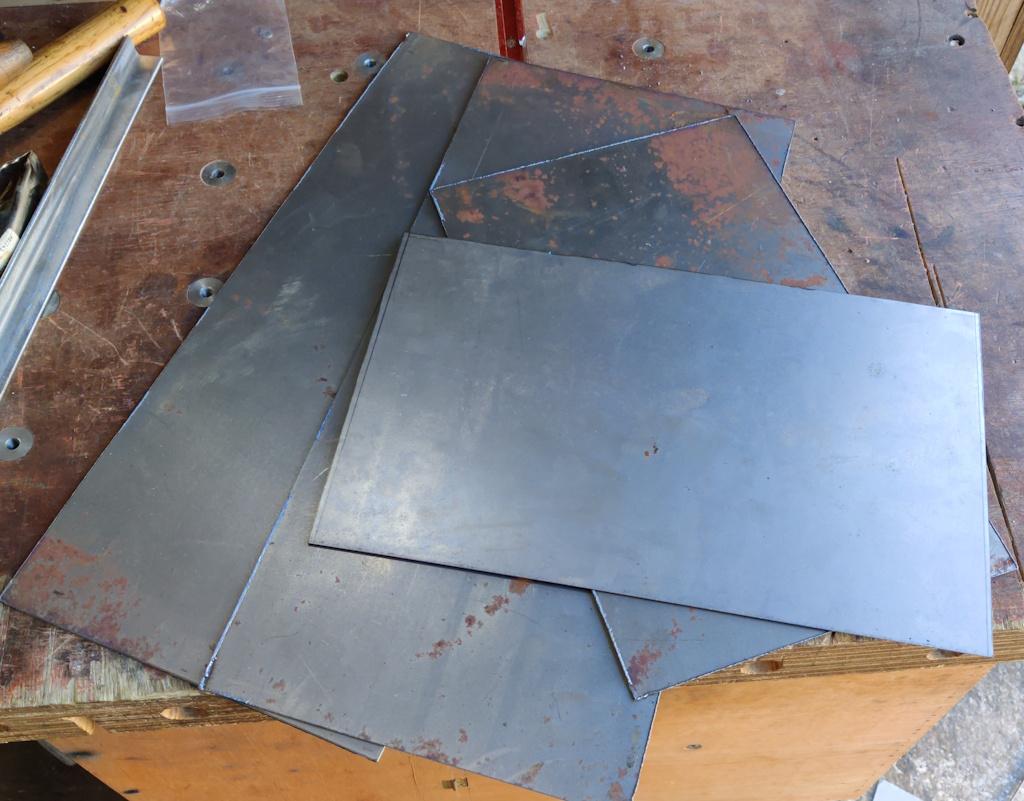

The last big job to sort out on the control cabinet (if you ignore the huge job that'll be wiring it all up!) was to cut out the sheets for the sides, top and bottom. Most of these came out of the same sheet of rusty 1.2 mm sheet, but I didn't have quite enough (without breaking into a new piece) and the bottom of the cabinet won't need much strength, so I just used an off-cut of (not rusty this time!) 0.8 mm sheet:

The 3D printer had again been active this morning preparing a couple of extra templates for plasma cutting:

The cutter quickly roughed out the holes (note that I just marked the positions of the two smallest holes as I figured they'd be easier to drill):

There will still be another hole in the side panel (for the wires from the door interlock), but that's likely to be circular so I'll just drill that as and when I've decided where it needs to go and what type of connector to use (probably a 3-pin DIN connector as I think I have some somewhere).

The rusty pieces then went into the citric acid bath (after I'd broken up the ice on the top layer). Hopefully it'll still work despite being even colder now than it was when I did the first two pieces.

There's not much more I can do with the cabinet until the rust has gone and those panels can be welded in place. I don't want to start wiring it up yet as I'd be worried about welding the panels in with all the wires and plastic parts in place (even ignoring the fact they'd probably get in the way). However, once they're welded in then I can bring the cabinet into the house and wire it up in the warmth! It'll all have to come out again when I paint the cabinet (a job I detest), but that's not going to happen for quite a while yet.

Page 17 of 35

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page