Heat Treatment Oven Build Process

Page 2 of 35

Posted 4th May 2024

Following advice from the MIG welding forum, I'm going to revisit the brick layout to make sure that the top layer of bricks is fully supported rather than relying on a glue joint. In the meantime though, a bit of discussion of the control system might be of interest.

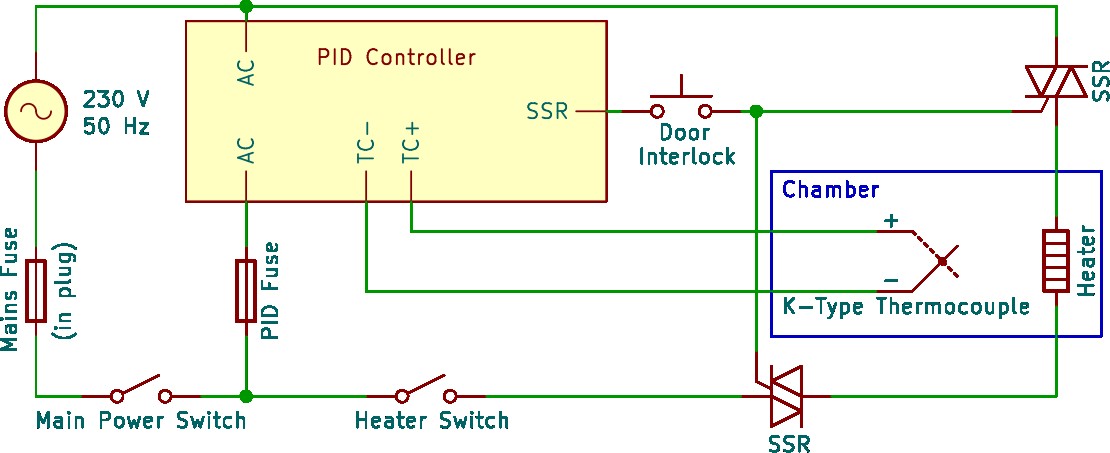

The diagram above shows a simple circuit diagram for the control system.

The oven will be controlled by a PID (proportional, integral, derivative) controller connected to the heating element via SSRs (solid-state relays, usually in the form of two back-to-back thyristors, often with an opto-coupler driving them, which I've omitted in the circuit diagram for clarity). In theory, one SSR would be sufficient; however, the typical failure mode of most SSRs is as a short-circuit and therefore it is safer to have two. The PID controller will read the temperature via a K-type thermocouple (K-type thermocouples have a maximum temperature of 1350°C) and control the current through the heating element in order to adjust the temperature to match a set-point.

Separate power and heating element switches are included so that the power to the PID controller can be enabled, the PID controller set up and then the heating element turned on when ready. An interlock is used to prevent the heating elements (which are connected to mains voltage) from being live when the door is open.

Choosing a PID controller is an important decision. As I see it, I've got four options:

- Pick a basic PID controller (circa £15–20) and accept that it can't do anything fancy like controlled temperature ramps.

- Pick a fancy PID controller (circa £90) that can do temperature ramps / soaks etc.

- Pick a mid-range PID controller (perhaps £30–40?) with an RS485/Modbus input. This would work much like the basic controller, but I could potentially add an external microcontroller to send commands over RS485 and implement temperature ramps / soaks myself if I ever felt the need.

- Implement the whole lot from scratch using a microcontroller and a home-designed circuit board.

I'm an electronics engineer by trade, so #4 is entirely plausible but it feels far too much like the day job and I doubt I could make that circuit board for less than the price of an off-the-shelf mid-range PID controller.

The third option (RS485 controller) is the most tempting of them all, but all the PID controllers I've found that have an RS485 input are either up at the price of the ramp/soak controllers or they can only handle temperatures up to 400°C.

That, unfortunately, leaves me with a choice of a simple, cheap controller or an expensive complicated one. At the moment I'm leaning towards the basic PID controller: if I find I need temperature ramps / soaks in the future, I can always replace the cheap one with a more expensive version at a later date.

Page 2 of 35

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page