Travel Tool Chest & Workbench Build Process

Page 137 of 144

Posted 16th September 2024

I started another box yesterday. I've been a bit inconsistent with taking photos, so there will be gaps in the explanation, but the general idea will hopefully be obvious. If anything is unclear or suitably intriguing, feel free to ask.

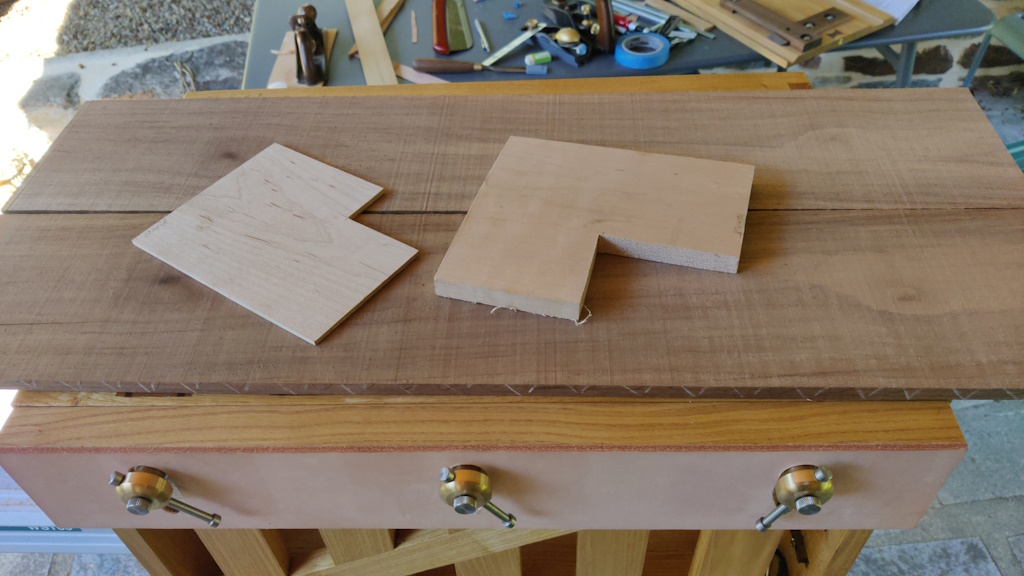

This photo shows the source material that I'm using for this box. Two bits of American Black Walnut, resawn from a thicker piece with the bandsaw when I was at home, along with a couple of offcuts of maple. Later on there will probably also be some sweet chestnut added to the mix.

This box is slightly unusual in that the thin bit of maple (which will be the back, fitted into grooves) is going to dictate the rest of the dimensions of the box. Normally I'd make a box and then cut a back/base to fit, but the maple piece is smaller than any of the other bits so it necessarily dictates the maximum size.

First job was making it rectangular - I'm amazed I managed to saw along that line without the thin bit breaking off:

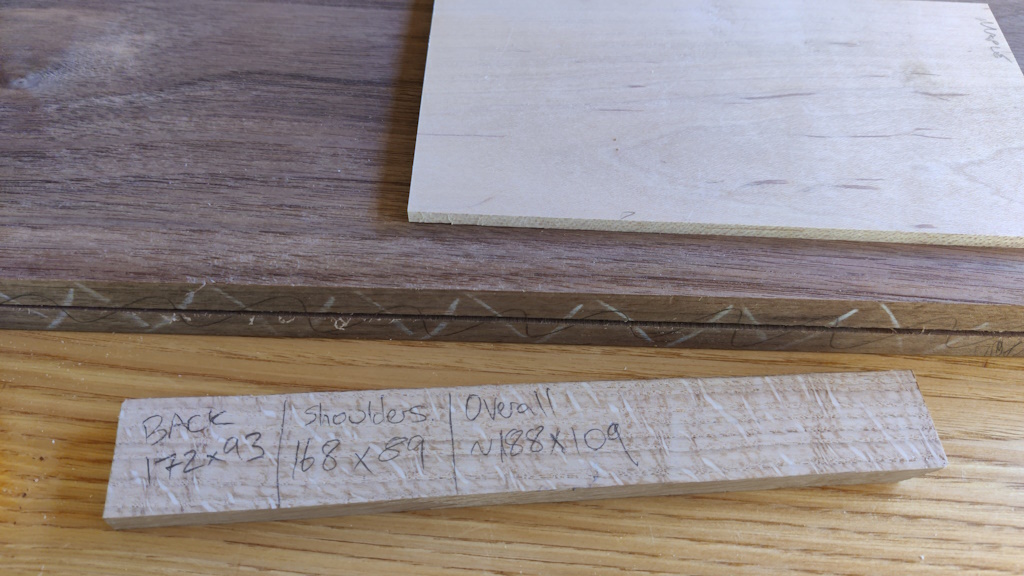

It then got shot to have 90° corners so it could be measured:

With the dimensions to hand, I could work out the distance between the "shoulders" (inside faces) of the box by allowing 2 mm all round for the maple bit to sit in the groove and then adding a bit (2×10 mm, erring on the side of excess) for the thickness of the box:

The walnut planks then got chopped up...

... and planed ...

... to remove the saw marks ...

... and bring them smooth ...

... and of the same thickness as each other:

The rough edges...

... then got planed smooth and square:

After some more chopping, I could label them in the sequential order, marking one as the top of the box as it looked marginally nicer than the one that will become the bottom:

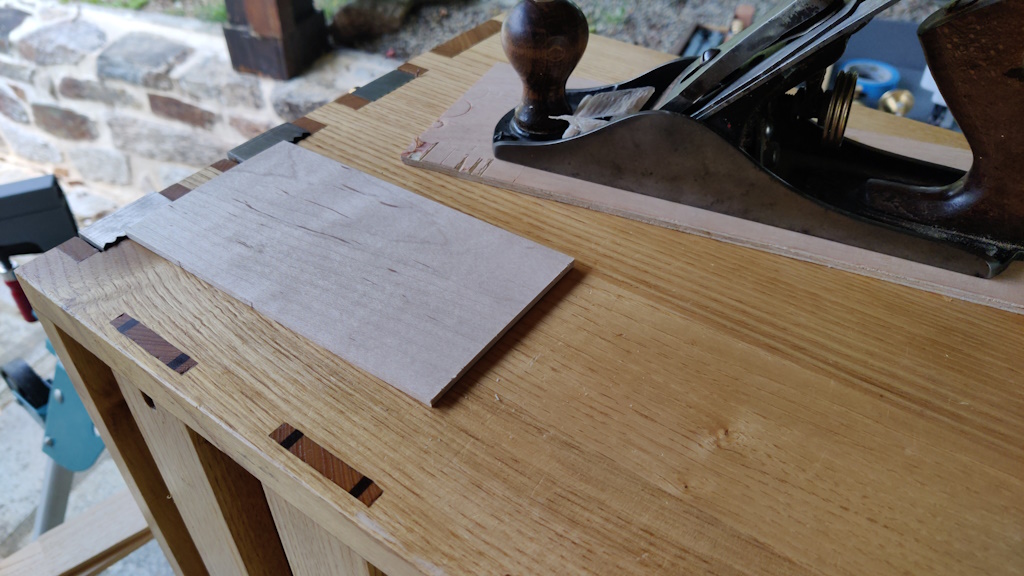

They then got shot to the dimensions marked on that offcut of oak I showed a photo of earlier. They're only 8.5 mm thick, so there's a lot of excess in those dimensions, but I decided to just deal with that once the box is glued up. The home-made block plane should make fairly light work of planing off the end grain: after all, it's still going strong despite me not having sharpened it at all since I've been here:

Next up was cutting tails and pins. I didn't take many photos (except when the sun was shining on the chest and making it look all arty!) but the process was the same as usual:

A bit of relief was added into the inside corner of the dovetails as usual:

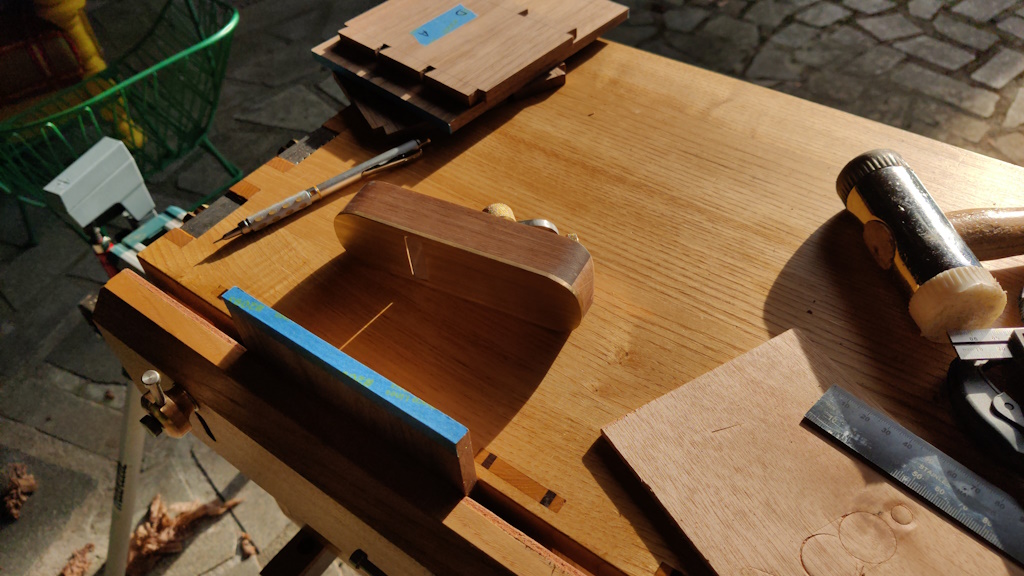

Then the box was assembled for a trial fit:

The groove for the back was ploughed in the same way as for the tea caddy (with blind grooves in the tail boards):

The faces of the back got a very light touch with a smoothing plane (the source material was already quite smooth):

Another slightly rough bit of walnut was dug out and chopped up:

Then it was time for more planing, to bring it to 4 mm (ish) thickness:

I thought I'd try my hand at a plain housing joint for this piece, so I marked up the two side pieces with knife lines, then started the housing with a 16 mm chisel, then used the router plane and a knife to finish it off, about 2 mm deep:

A trial fit, showing how the shelf and the back fit into the sides:

That felt like a good time for a (fish) glue-up, with what is probably a rather excessive number of clamps:

In case you haven't already guessed, this box is going to have a couple of drawers (with the other bit of maple being used as the drawer fronts). I'd wondered about having a narrow strip of maple visible at the front to separate the drawers, but I think instead I'm going to make the front of the bottom drawer stick up a bit and go over the front of the middle shelf.

The next job is probably to start planing the material for the drawer front (the thicker maple piece) and sides (probably sweet chestnut as I have loads of it) and figuring out what to use as the drawer bottom.

Page 137 of 144

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page