Travel Tool Chest & Workbench Build Process

Page 45 of 144

Posted 18th March 2023

Another thing I'm thinking about while pondering on the drawer count is all the various types of workholding this chest needs to handle. When I originally came up with the concept, it had an array of holes on the top and the back and those holes would handle most of the cases I wanted to deal with.

The cases I want to be able to handle are (all with relatively thin bits of wood):

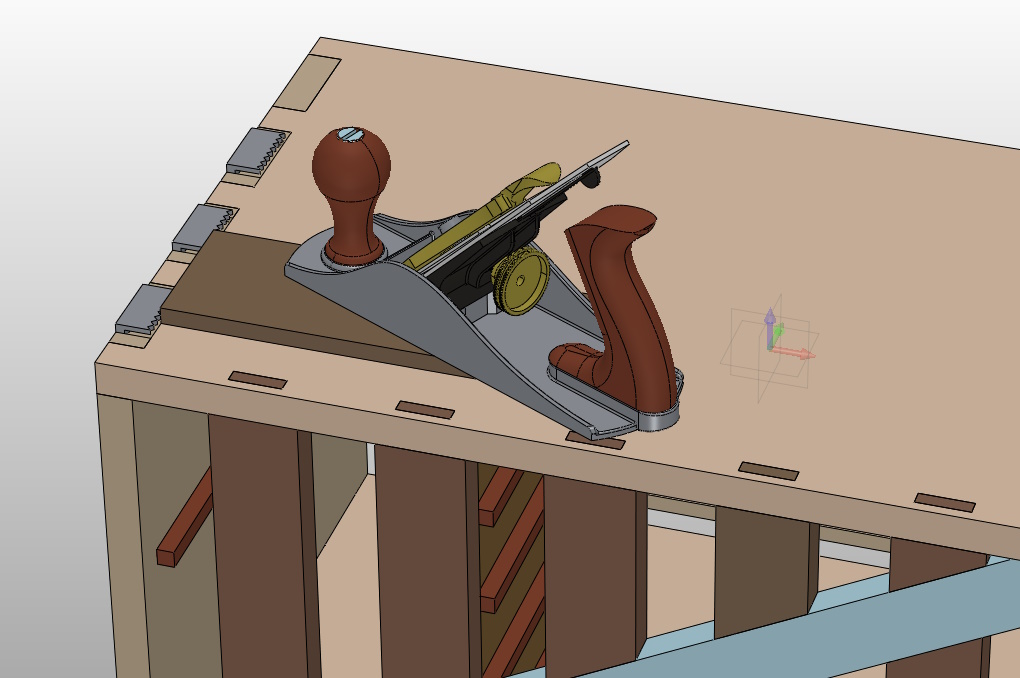

- Planing a surface against a stop

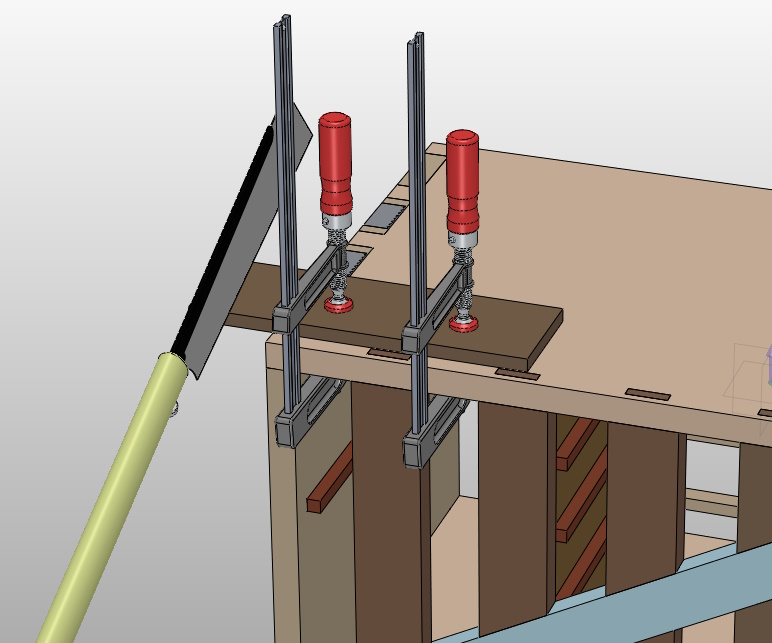

- Clamping a workpiece to the top so that I can (e.g.) saw a bit off the end or the side

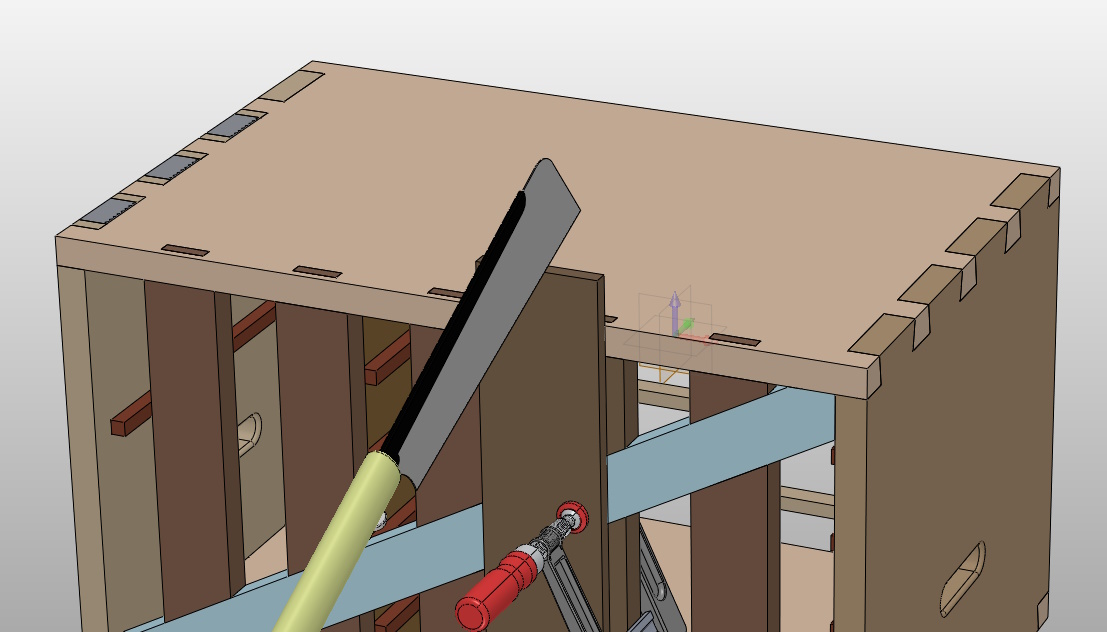

- Clamping a workpiece to the back so that I can saw or mark up dovetails

- Clamping a workpiece to the top with full access to the top surface for grooving / routing

The first one's nice and easy: that's what the planing stops are for:

The second one might be okay. The anti-racking thing on the back might get in the way of clamping stuff on the right-hand side of the back, but I can either hang it off the left or spin the box round and clamp it from the front:

Ideally, there would be a way to clamp stuff leaving the whole of one long edge clear, but for relatively narrow workpieces, that would require a very deep jawed clamp (about 300 mm from jaw pad to shaft). That's one disadvantage of losing the holes in the top, although I do like the fact that the top is actually sealed and stops stuff falling into the drawers (although there will still be a bit of a route in from the back due to the gap where the drawer runners are).

The third one should be fine:

The last one I currently have no solution for. My dog hole tail vice would have worked (for stuff over 12 mm thick) if the holes were there in the top, but it obviously won't help without those holes.

I'd wondered about something akin to a machinist's low profile clamp, but bearing on a dovetail groove rather than a t-slot (as I suspect I have a little more chance of cutting a dovetail groove with hand tools than doing a t-slot), but the groove sounds very difficult to get right and I'm not sure it's a very good answer anyway. An easy option would be to plough a 19 mm wide groove in the top and set some t-slot extrusion into the top (which could then be used with some sort of low-profile clamp), but that seems a bit naff...

Needs more thought.

Page 45 of 144

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page