Travel Tool Chest & Workbench Build Process

Page 44 of 144

Posted 18th March 2023

The sun was back out again this afternoon so I opened the garage door and got on with a bit more wood bothering. I started by taking those walnut pieces and slicing the heartwood bits into strips. Where they were nice and wide, I did it like this:

Once things got more narrow (which wasn't on many pieces as there was so much sapwood), I used a different approach:

That left me with a pile of strips that were planed on three sides but inconsistent thicknesses:

This felt like a good time to cut them to (approximate) length and shoot the ends square. Given they're only approximate length, shooting the ends square is probably pointless at this stage, but I like using the shooting board and it didn't take long:

I then resurrected a jig that I made for making Kumiko. It has a slot sized for making 16 m × 3 mm strips, so I used a router plane to make that more like 22 mm × 9 mm (I didn't actually measure the dimension, I just made it wide enough for the widest strip and thinner than the thinnest strip). It was then a quick job to bring all the strips to the same thickness:

Et voila:

The ones on the left (which are about 22 mm wide at the moment) are intended to be the strips across the front between the drawers. The ones on the right (which are about 16 mm thick at the moment) will be the drawer runners.

I've made enough for four sets of runners (and hence 5 drawers) on the left hand side and one set of runners on the right hand side. Now I find myself at the crunch point: I need to decide how many left-hand side drawers to make: whether to put the saws in with the measuring tools and have four drawers or separate them and have five. Every time I think about it I change my mind, but I'm going to have to commit soon!

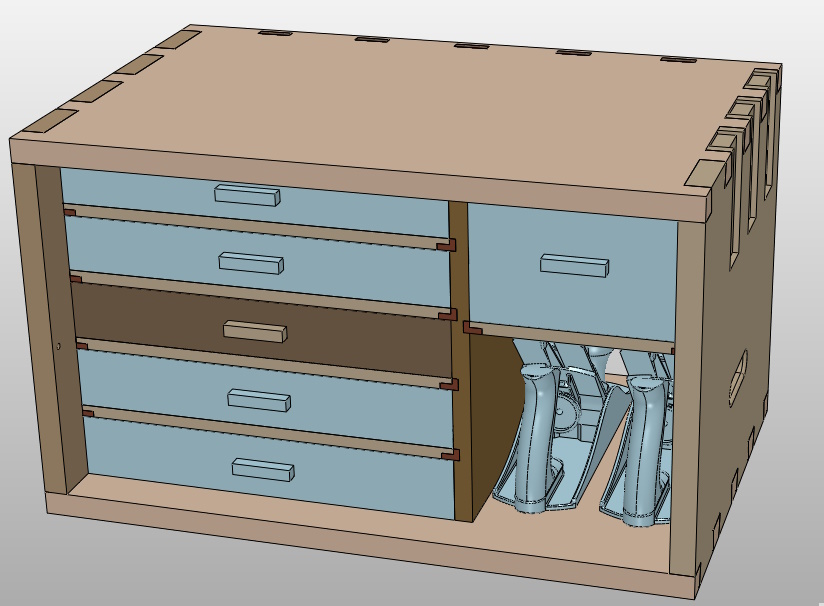

I also need to decide what to do about joinery for the front strips. I'm very tempted to have a go at the mini blind mortice suggested by AndyT on the woodworking forum. Alternatively, I could do the half-lap joint shown in this CAD model:

The big advantage of the half-lap joints is that I could size and fit the strips across the front (drawer dividers) after I've assembled the chest frame. Also, the drawer runners could be fitted into their housings before assembling the chest. That would probably make the chest glue-up much less stressful.

Doing it with blind mortices would look better (assuming I don't make a mess of what would probably end up being a circa 3 mm mortice & tenon!). However, I'd have to get the length of the drawer dividers right in advance and the glue-up would involve dovetails, the middle upright's housing joints, the wedged mortice and tenon joints, the blind mortices in the drawer dividers and the housings for the drawer dividers. I'd then be reaching into fairly narrow slot to do up the screws at the back of the drawer runners. That all sounds fairly stressful!

Making that decision is less pressing than deciding on the drawer heights (as I think the next job is to cut the housings for the drawer runners), but it's definitely something I need to decide very soon.

Page 44 of 144

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page