Woodturning Lathe Build Process

Page 12 of 61

Posted 18th February 2024

After a bit of an overdue tidy-up, I decided to do a bit more work on the tailstock. I started by mounting the tailstock spindle in a collet chuck in the mill and milling a 5 mm wide slot along the EN3B.

I overshot the soft-ish EN3B bit a couple of times and went into the very hard Morse taper adaptor bit (the transition isn't obvious as I'd cut the end of the Morse taper adaptor slightly on the lathe with a carbide tool). Both times I broke the end mill I was using so this ended up being a three end mill job!

Once the slot was done, I took the brass piece that was used as a mandrel yesterday and bandsawed off the bit I want to turn into the the tailstock sleeve. I mounted it in a collet chuck with about the same amount hanging out each end of the collet and then went up through the drill bits, this time stopping at 22 mm:

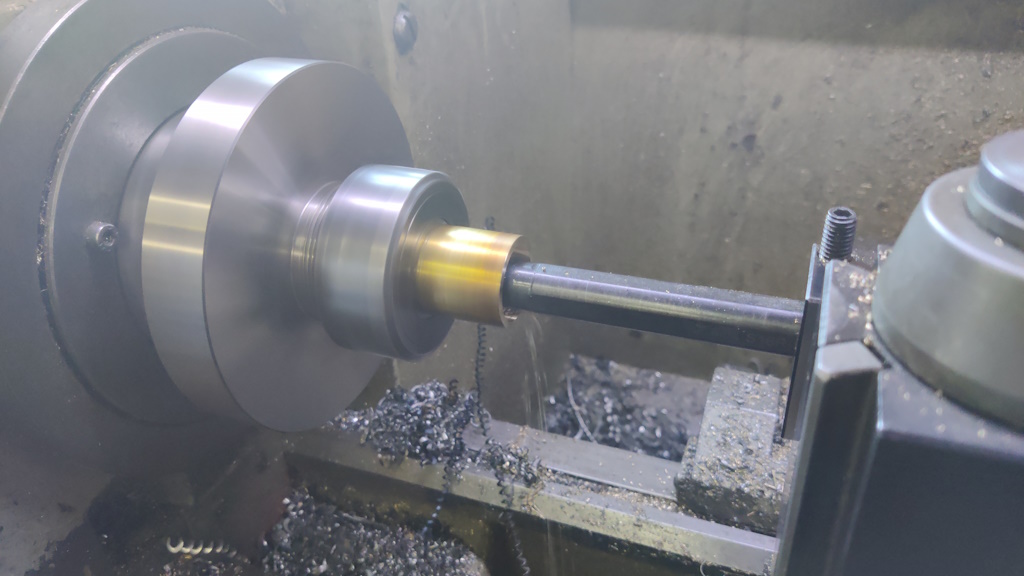

I then used the boring bar, taking very light passes and also spring passes (not changing the setting, just doing another cut) to gradually increase the hole diameter...

... until the tailstock spindle would slide smoothly through the bore:

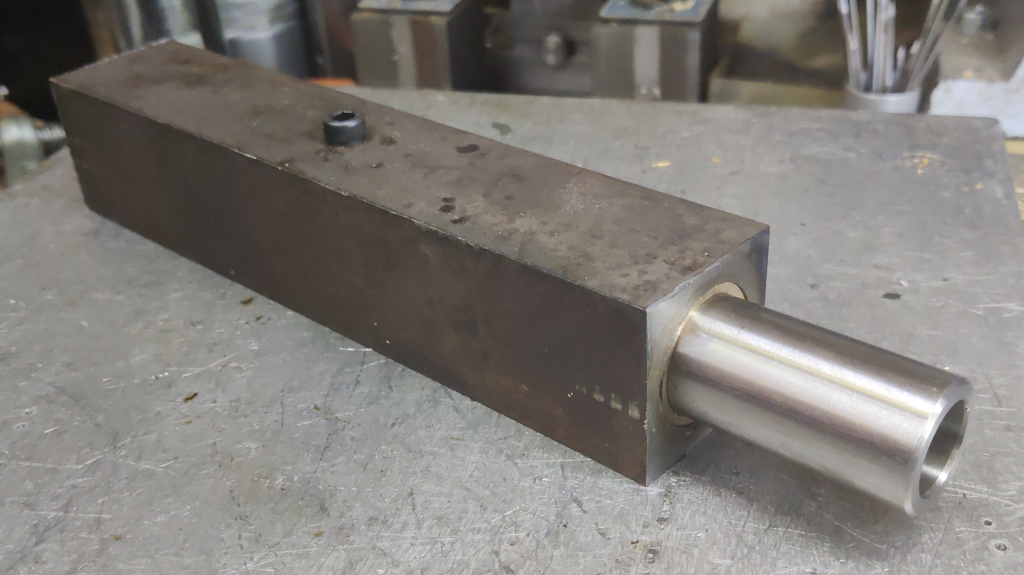

The brass sleeve was then shoved back into the tailstock body and a hole spot drilled, drilled and tapped through both the steel and the brass:

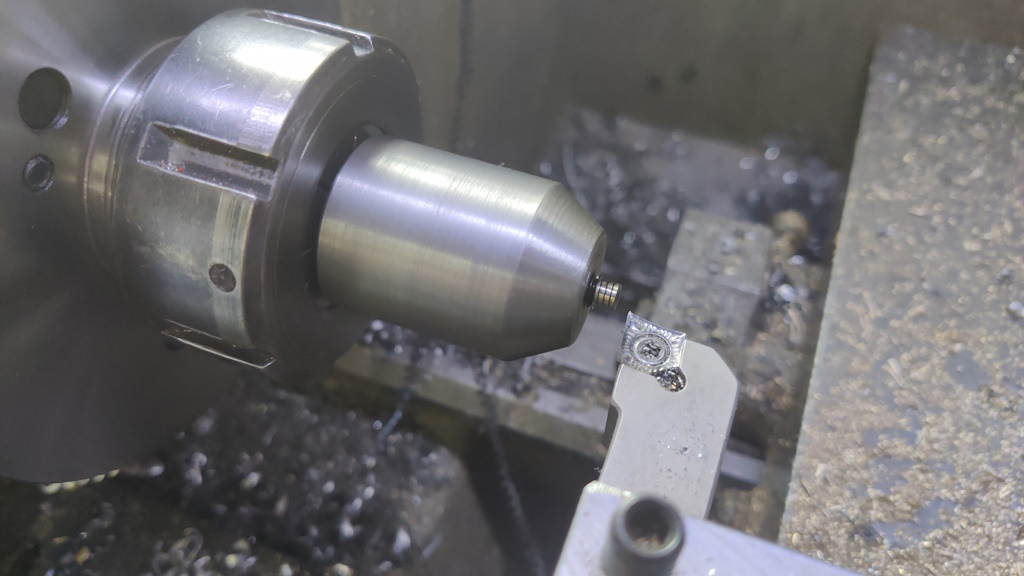

The anti-rotation screw needs to have a smooth end, so I dragged out a lantern chuck I made many years ago:

With that held in the lathe, I could turn the last few millimetres of thread off to give a smooth end with a diameter slightly under the 5 mm of the milled slot:

That's the bulk of the work for the tailstock body done: the spindle slides in and out smoothly, but won't rotate:

I still need to do something about retaining the handwheel bearing and I'll probably round off the top corners. I also need to make the base that will lift it up to the right height, but I'm pleased to have got this far. Next job will probably be to make the leadscrew that will pull/push the tailstock in and out.

Page 12 of 61

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page