Woodturning Lathe Build Process

Page 17 of 57

Posted 27th February 2024

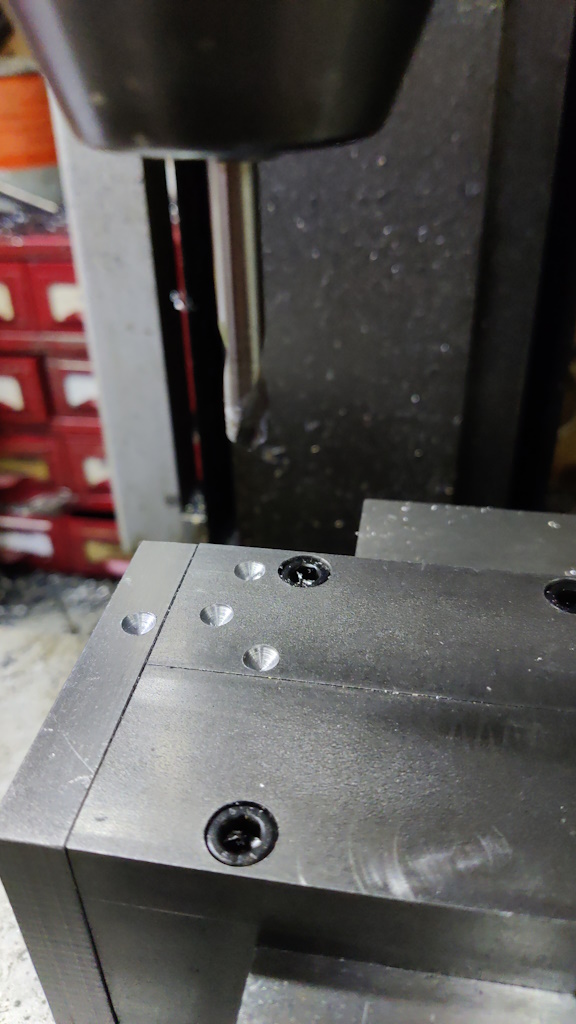

I had a hour or two free this evening so I popped out to do a bit more on the tool rest slide. Following advice on tool rest height adjustability, I've decided to abandon the two tapped holes I'd originally planned to use for holding a tool rest support in place. Working on the other end of the tool rest slide, I used a spot drill to position some (very carefully thought-out) hole locations:

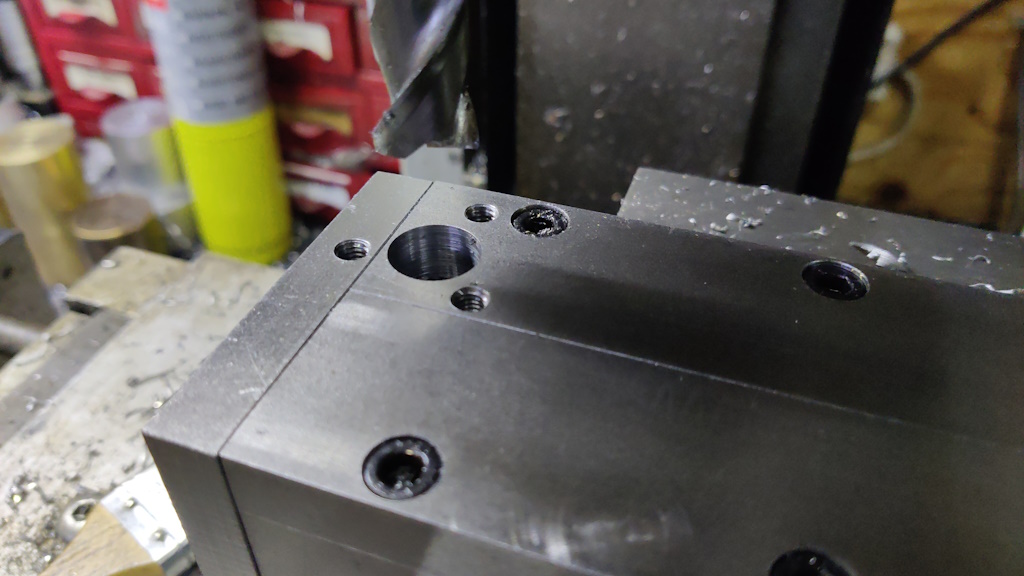

The holes were then completed. The outside ones were drilled and tapped M6; the middle one was drilled out to 16 mm, finishing with an end mill for final sizing:

I then flipped the tool rest slide over and milled a clearance slot at the bottom:

The eagle-eyed among you will note that I've also added a small drilled hole in the end plate (and a matching one at the other end).

Next up was a bit of 40 mm EN1A, which was mounted in the three-jaw chuck, drilled, bored and reamed to 16 mm.

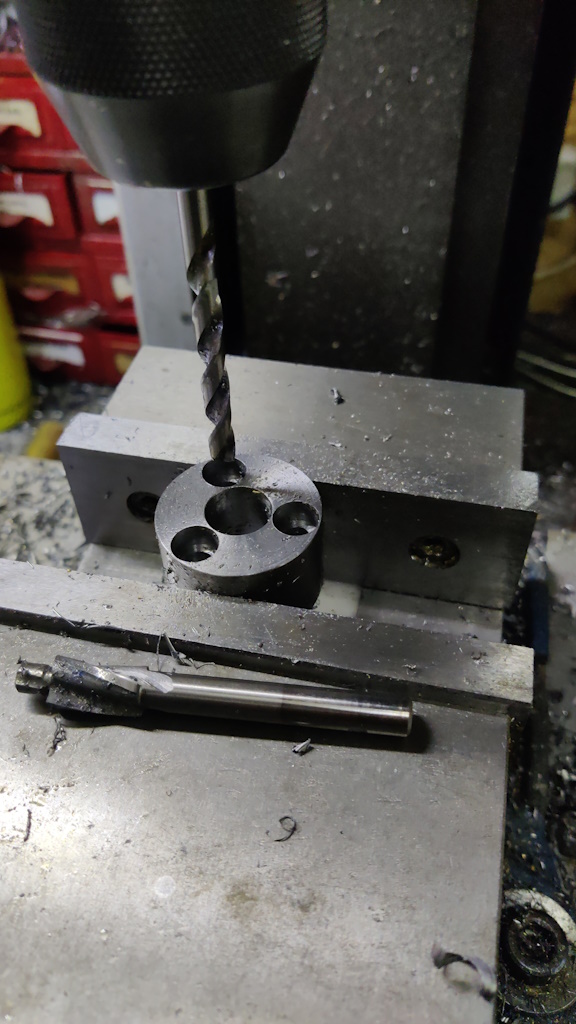

After parting off, reversing and cleaning up the back face, it was then mounted (in a somewhat precarious way as I was being lazy and only drilling, not milling) and the axes zeroed on the centre of the bore:

Three holes could then be drilled and counterbored:

I did those holes in a slightly odd order: I spot drilled them, drilled them to 24 mm depth, counterbored them, then completed the through hole. The reason for that was that the vice mount was a bit precarious (it would have been better to have a v-block between the part and one of the jaws) and I wanted to leave the parallels in place until the last minute.

Once those holes were done, I shoved a couple of drill bits in the holes and used them to align it in the vice such that a drilled and tapped hole would go roughly central between the two tapped holes:

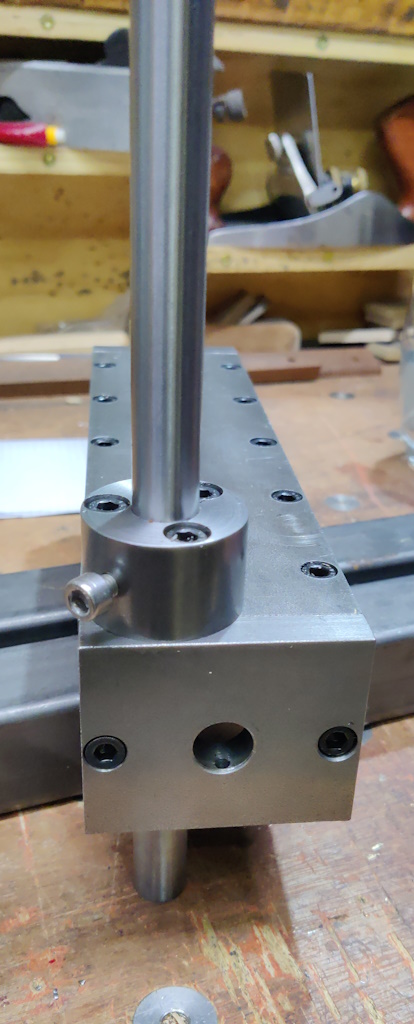

It could then be mounted to the tool rest slide and tested with a bit of 16 mm silver steel bar and a handy cap screw (which will get replaced with a knob of some sort in due course):

It was starting to feel like I was getting close to the finish line, so I thought I would check my ambitions somewhat by writing down a list of all the parts I could think of that still needed to be made. There were 44 of them! I'm still a fair way from completion.

Admittedly, some of those 44 are really simple things like the handle for the tailstock handwheel, which is basically a tube. However, some of them are complex (and possibly made up of multiple parts) like the motor mount and the bed/feet assembly, neither of which I've really started to think about yet.

Page 17 of 57

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page