Woodturning Lathe Build Process

Page 2 of 55

Posted 8th February 2024

After spending all of last year on my rather epic tool chest / workbench project, I've been flitting between various fairly simpler projects. I've now decided to get started on another relatively complicated project that should challenge me a bit. It probably won't surprise you to hear that this will probably be done in an overcomplicated way, but as usual: as long as I enjoy the process, I'll be happy.

The challenge I've set myself is to make some new chisel handles out of English Walnut. The choice of wood is based on the fact I've got a lump of English walnut that's quite short along the grain but quite wide and thick, so I think I can get lots of chisel handles out of it, but there's not much else I can think of that I could do with it.

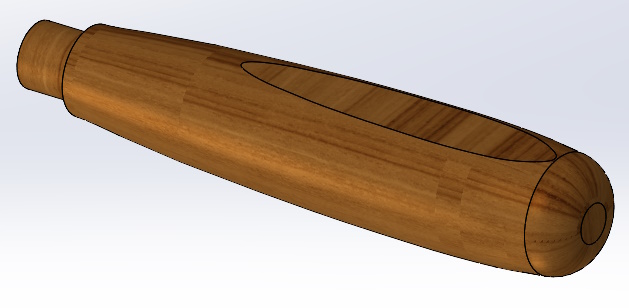

This is roughly what I want the chisel handles to look like (they're 30 mm thick at the thickest point):

I've 3D-printed some test pieces to get an idea of how well they fit in the hand and they feel quite nice to me, so it gives me something to aim for. No doubt the design will get tweaked later.

The reason this is going to be challenge is two-fold.

Firstly, I'm going to try to make the chisel handles without buying anything at all: everything I use has to come from stuff I've already got (I reserve the right to change my mind about that rule if it gets too hard, but that's what I'm aiming for).

The second reason it is a bit of a challenge is that the chisel handles could be described as Round Objects ("Who is Round and to what does he object?" I hear the cultured among you cry!). Round objects are best made on a lathe. Wooden round objects are best made on a wood lathe, which I don't have. I don't really want to shower my metal lathe in bits of wood (as that isn't considered a good idea) and besides, it doesn't run very fast, so probably wouldn't make a very good wood lathe anyway.

Step 1 of making chisel handles is thus: make a lathe (and some tools to use with it, probably starting with a spindle gouge). Doing this without buying anything could be a bit of a challenge, but I do have a very well equipped workshop and quite a lot of material of various different types, so it's probably not as challenging as it would be for someone with a more normal set of tools / materials. As a lot of the design will be based on what I find while rummaging through drawers, I probably won't model it in CAD: I'll just make it up as I go along and hope for the best.

I've never used a wood lathe before (I've never even seen a spindle gouge apart from on photos on the web), so there will be an extra challenge at the end in learning how to turn.

To make it a bit more challenging, I'd like the lathe to be useful for more than just these chisel handles, so I'm going to try to build some versatility into it. Also, the main reason I've never bought a wood lathe is lack of space to store it, so I'd like this to be easy to dismantle for storage. My initial thoughts on versatility are that I'll try to use Morse Taper sockets (probably MT2) in both headstock and tailstock and I'll turn a thread (probably M33×3.5) on the spindle so that I could potentially fit a standard chuck in future. I'm not really interested in "pure turning projects" - making projects like bowls and such like: I'm only really interested in turning for making parts for other projects (tool handles, drawer pulls and such like), so I don't want/need to make a lathe that can handle big diameters.

Suffice to say this project to make wooden chisel handles isn't going to involve much wood work (but that's good, because it's cold and wet outside and it's quite hard to do woodwork in my tiny workshop without having the door wide open).

Page 2 of 55

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page