Woodturning Lathe Build Process

Page 30 of 43

Posted 10th March 2024

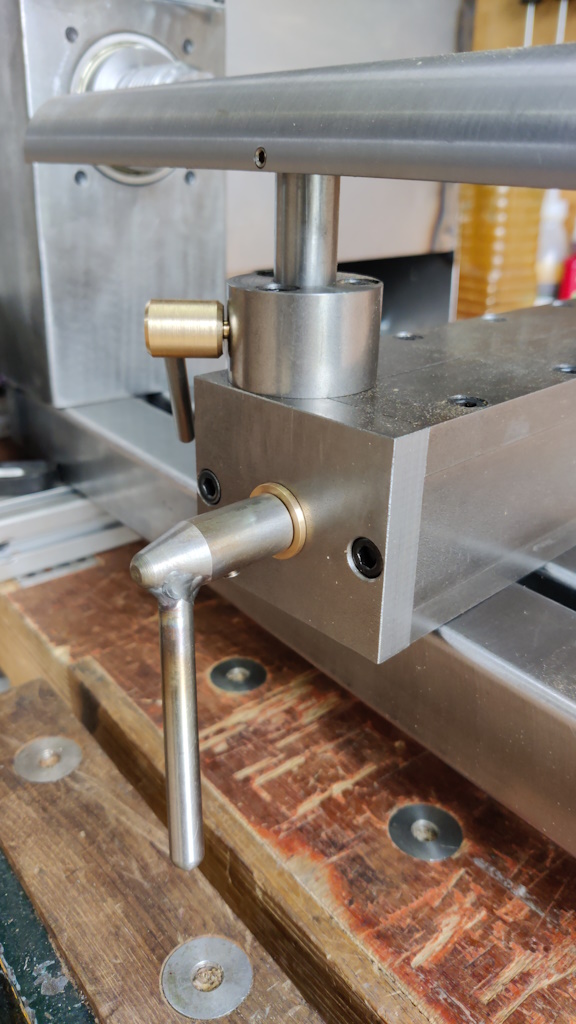

Yesterday's attempt at gluing (the fourth one I think) hadn't cured overnight, so I started today by welding the knob in place:

It then got a bit of attention with a wire brush before fitting it:

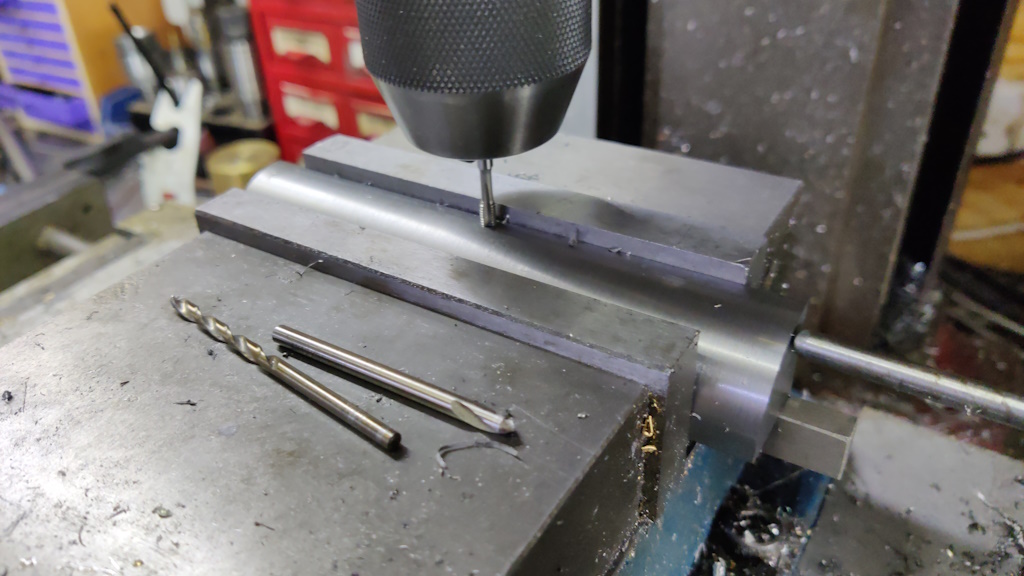

The next job was to work on a shorter tool rest. Being shorter (and aiming for shorter than the stock that it's made from) allows for a slightly tweaked process of making it. The first thing I did was clamp a vice in the mill vice and used that second vice to hold the stock upright. I could then drill a centre hole, just in one end this time. As I was drilling more accurately (using an edge finder on the edges of the stock and moving in a controlled amount) by virtue of being on the milling machine, I could use a slightly larger centre drill without risk of blowing out the edge:

I could then mount the piece in the four jaw chuck (using a couple of offcuts of steel as I couldn't get the jaws close enough to each other to allow such off-centre turning):

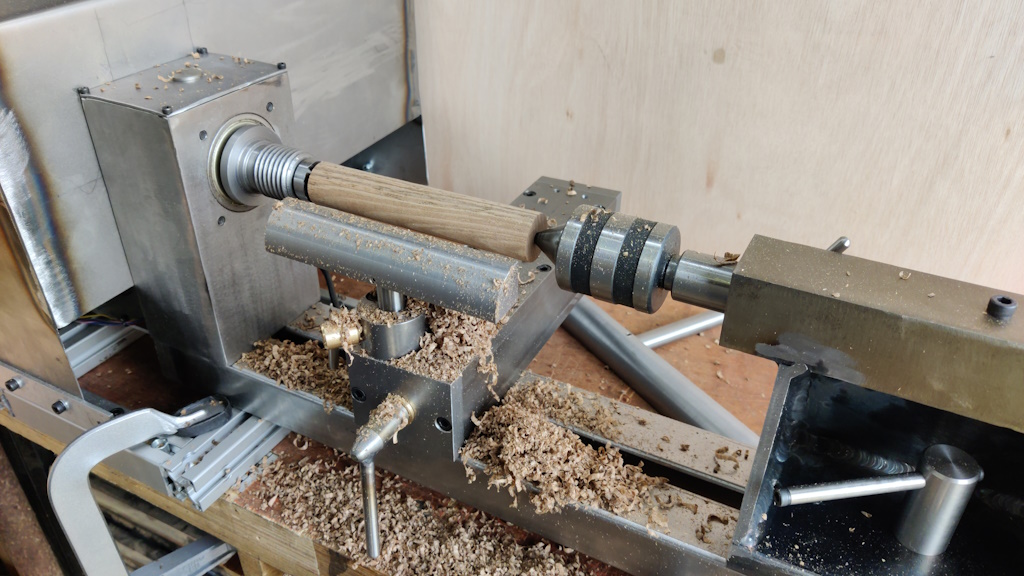

As it was held quite robustly in the chuck, I could run the lathe quicker than I did when making the longer rest and that meant that turning it down to size was much quicker:

After using the bandsaw to chop it to length, I milled the two ends with an end mill (which handily gave me a very accurate gauge of the centre) and then drilled the hole for the support post:

After turning it through 90°, I drilled and manually tapped the the grub screw hole (using the chuck to keep the tap aligned, but turning the spindle by hand):

The two rests side-by-side for comparison:

With that done and a bit of walnut made octagonal with the bandsaw, there was really nothing for it and I bravely (stupidly?) decided to set up a camera on a tripod to video my very first attempt at woodturning...

The bit of plywood in the background was there to keep the shavings from covering all the tools mounted on the wall, although it didn't seem that bad in practice.

After reviewing the video on the camera's screen, I realised it wasn't that clear (I'll never be a youtuber!), so I moved it a bit closer and filmed my second ever attempt at woodturning!

A couple of photos of the result:

I also braved a second attempt (with the camera off this time) and turned a longer piece with the long tool rest (the photo was taken after vacuuming up the mess!):

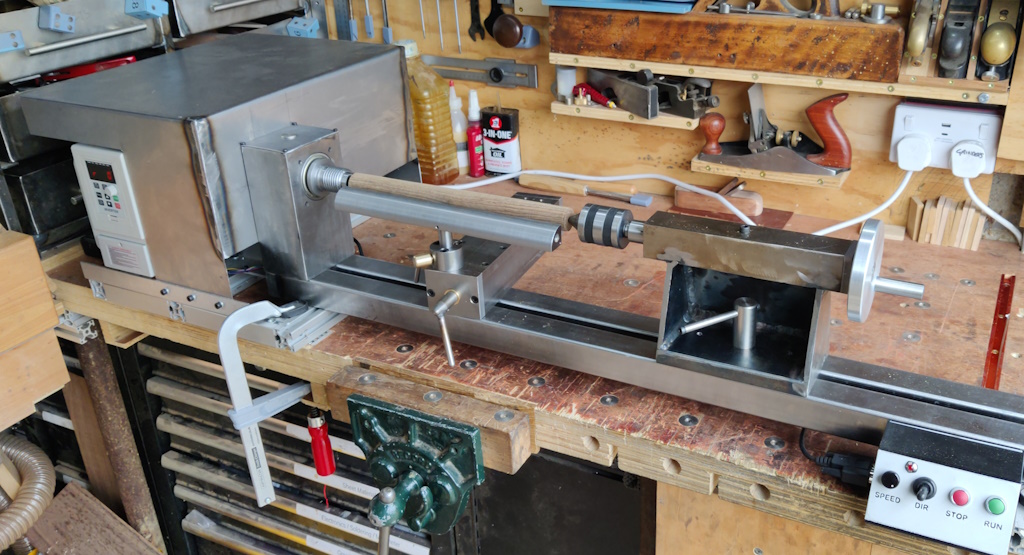

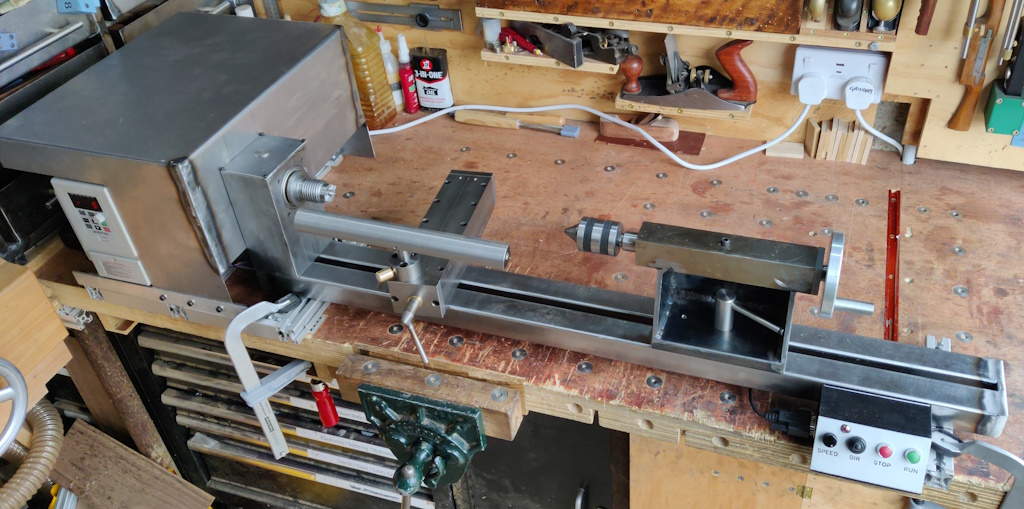

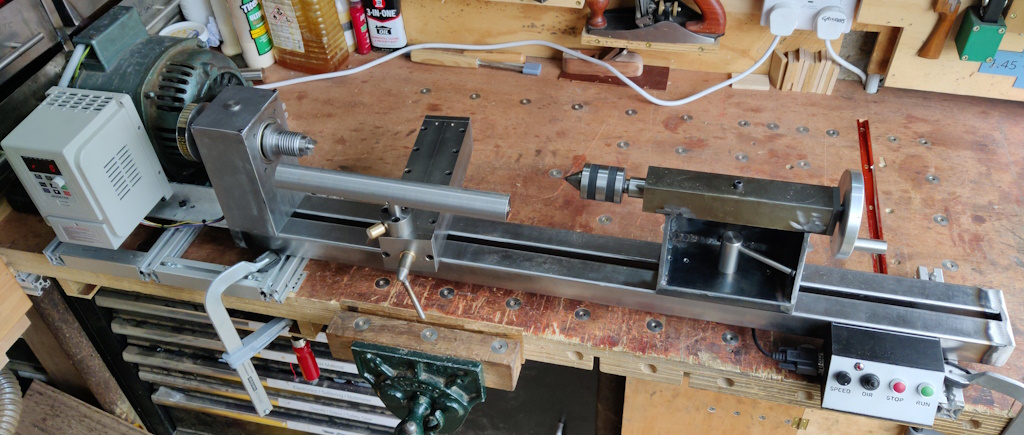

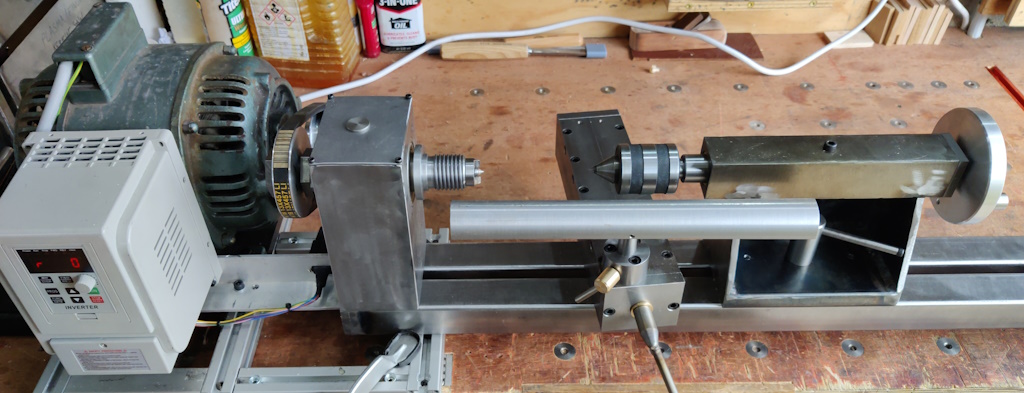

Some more photos:

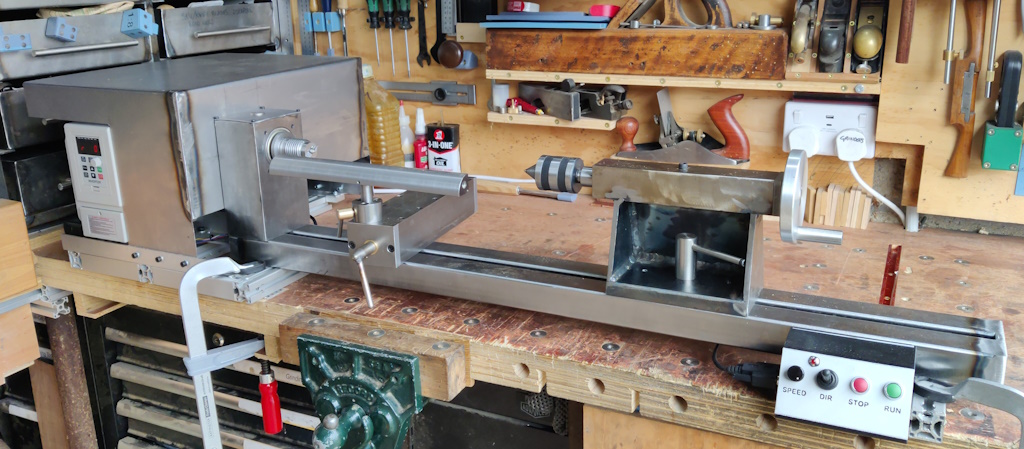

With the cover off:

From my point of view, that's basically a finished lathe. I started on 8/2/2024 and today is 10/3/2024, so it has taken me just over four weeks to make. When the weather gets a lot warmer, I'll paint the bits of it that I think would benefit (painting Tractol is a lot easier in warm weather I think). Immediately before that I'll probably run the angle grinder over all the corners to round them over a bit. However, I'm quite happy to put painting off: I absolutely detest painting!

It seems to work pretty well from what I can tell with zero experience. I'm sure I'll do a lot more playing/experimenting over the next few weeks (especially once I've bought some proper lathe tools to go with it).

This afternoon's job will probably be to have a go at turning a chisel handle (as I said I would try to do that without buying anything, so I need to make it with the tools I've got).

Page 30 of 43

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page