Woodturning Lathe Build Process

Page 33 of 43

Posted 23rd March 2024

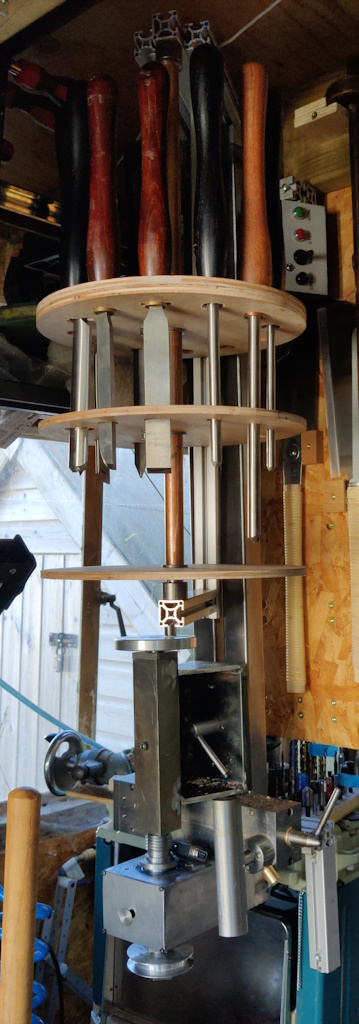

Most of today has been spent making a simple "Lazy Susan" tool holder. It's made out of some plywood pieces (which were made circular with an electric router) and various bits of steel, aluminium and copper. The frame is made out of more of the 3030 extrusion that I got out of the skip (I've still got loads left; it's really handy stuff to have around). The bar that runs through the middle is a bit of 12 mm diameter mild steel (the cheap stuff sold for construction applications). The ends of the bar were turned down to 8 mm and then various bushes were made out of 30 mm EN1A to centralise the 22 mm copper pipe that separates the layers. The ends of the bar fit into some more steel blocks that are screwed to the aluminium extrusion and have a hole bored for a skateboard bearing (which are very cheap to buy and I have quite a lot of).

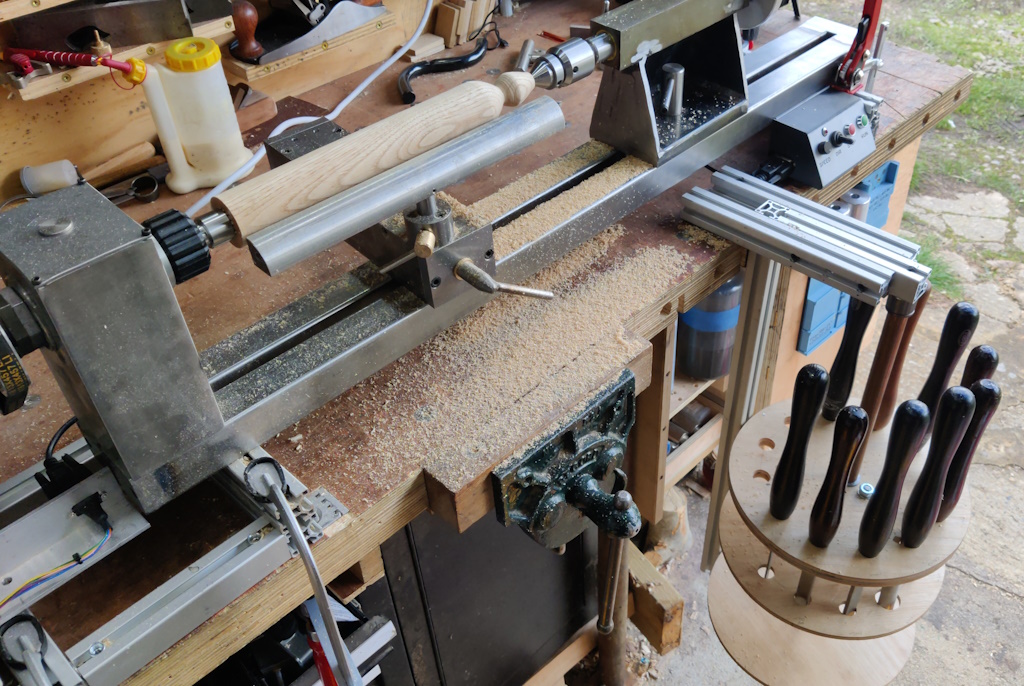

As the bar runs in bearings, it spins very freely (possibly a bit too freely: it rotates when there's a gust of wind!). It's attached to the bench using a simple 20 mm diameter bit of steel screwed to one of the bits of extrusion: that drops into a dog hole on the bench. As a result, it can be placed anywhere along the length of the bench, although I found this position quite comfortable for use:

I also drilled & counterbored some holes in a bit of 25 mm × 50 mm aluminium bar and screwed it to the holes in the end of the lathe bed:

The bigger of those holes is 21 mm diameter and allows the tool holder to hang off the end of the lathe bed when the lathe is stored away:

As well as the motor storage (which I'm putting off for now) I still need to figure out storage for the chuck & jaws and also all the various Morse taper bits and bobs. For the latter, I might make something that fit on the Lazy Susan in-board of the tools, but I haven't decided for certain yet.

After all that, I thought it would be good to have another go at turning with a spindle gouge and I think something clicked this time: it felt a lot more in control. I think (although I'm not certain) that when I'd been experimenting before I was trying to control the tool with my left hand (by the rest), whereas today I was doing a lot more with my right hand (on the handle) and it felt a lot easier. I'll keep practising, but this simple bit of shaping seemed fairly straightforward:

The finish is a bit rough (lots of lines where I didn't maintain continuous smooth movement: a problem I suffer when TIG welding as well!), but hopefully that will get better with practice.

Page 33 of 43

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page