Woodturning Lathe Build Process

Page 42 of 65

Posted 28th August 2024

The lathe has had a couple of minor upgrades since I finished it a few months ago. The first of these was something that I was always considering doing but didn't as I didn't have the required material (and I was trying to make it from what I had in stock). I've since bought a couple of metre long 40 mm × 8 mm steel bars, so these got attached to the bed with some screws from underneath:

This was just a case of drilling and tapping a row of holes in each bar and then drilling the box section through with a clearance drill and then opening out the bottom side of the box section to allow clearance for the head of a cap screw. The bars could then be clamped around some 12 mm thick spacers (to get the two bars perfectly parallel) and then screwed to the bed.

The advantage of this upgrade is that it guarantees that the two sides of the bed are parallel for the whole length. A little bit of distortion is inevitable when welding, so there was a very slight bow in the box section. It was much more minor than I expected and probably would have been fine: with the tailstock adjusted to be a snug but sliding fit in the middle of the bed, it ran smoothly but snugly along most of the bed but was a bit too tight in the last 60 mm or so near the right-hand end of the bed. For all but the longest spindles, that wouldn't have been a problem but with the extra bars added it runs smoothly along the entire length of the bed and was also much easier to set up as I could ditch the eccentric 11 mm diameter adjuster pins shown in this image...

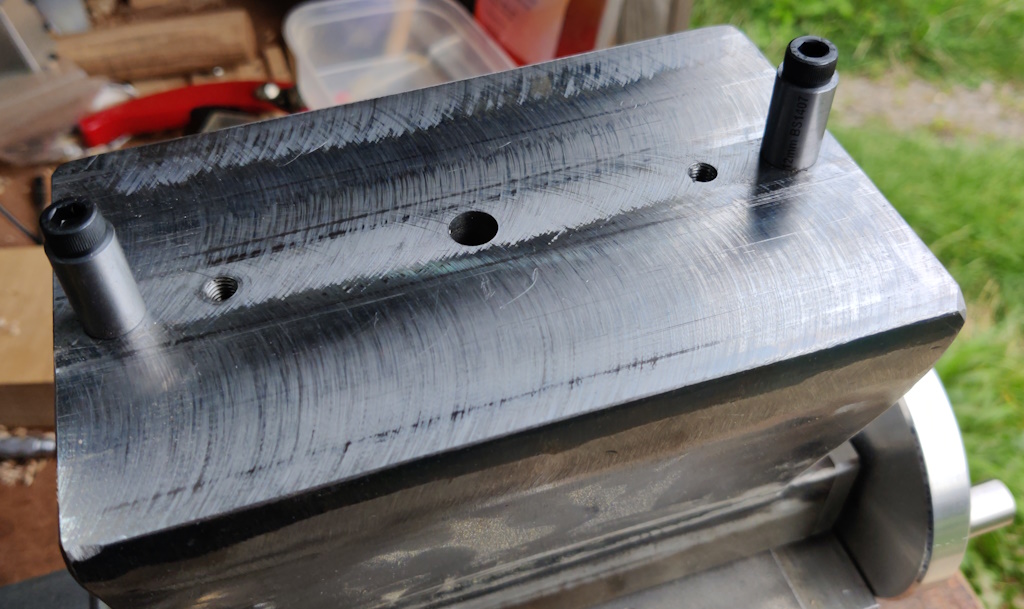

... and replace them with plain 12 mm diameter pins with a central 6 mm hole:

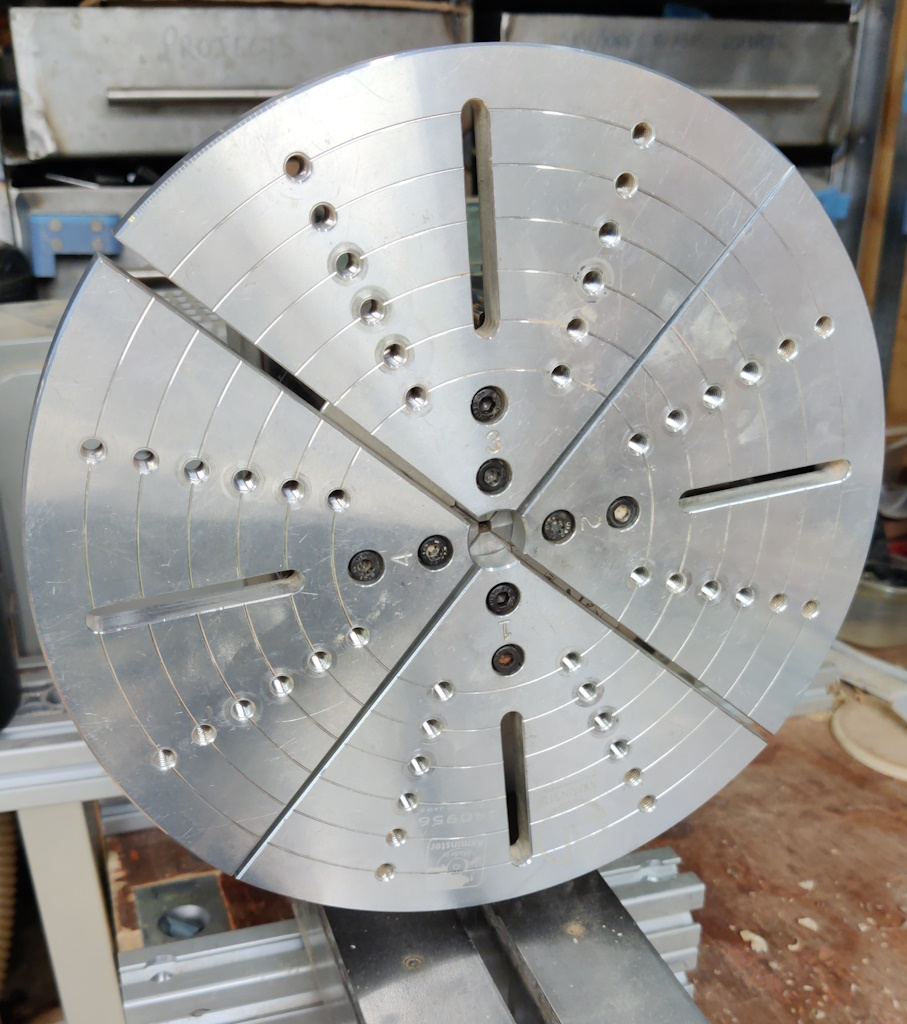

The second modification was also fairly simple. When I visited Dolphin Antiques a few months ago, one of the cheap sets of chuck jaws I bought was a set of button jaws (also known as Cole jaws I believe). Since using them for a couple of bowls, I've found that they're slightly limited in that the bed clearance (centre height) isn't quite enough to allow the full range of chuck jaw movement when these jaws are fitted. With the jaws fully closed, there's plenty of clearance:

If the chuck jaws are opened all the way, the button jaw plates hit the bed:

There's enough travel there to be able to clamp down on most bowls but it's a bit marginal and it tends to require the bowl to be fitted before the chuck goes on the lathe, which just makes the whole process more awkward.

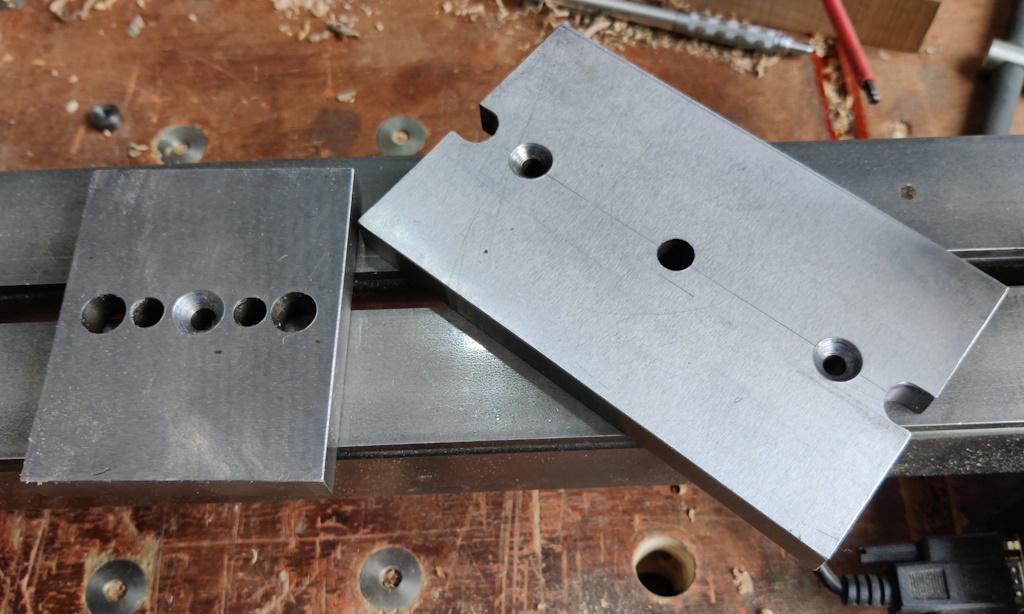

Conveniently, I had a handy lump of 12 mm thick steel plate in a drawer and it was big enough to be cut up to provide these two bits, which had the edges milled and a bunch of holes drilled:

Those plates go under the head- and tail-stock and raise the centre height by 12 mm...

... allowing clearance for the button jaws to be fully used:

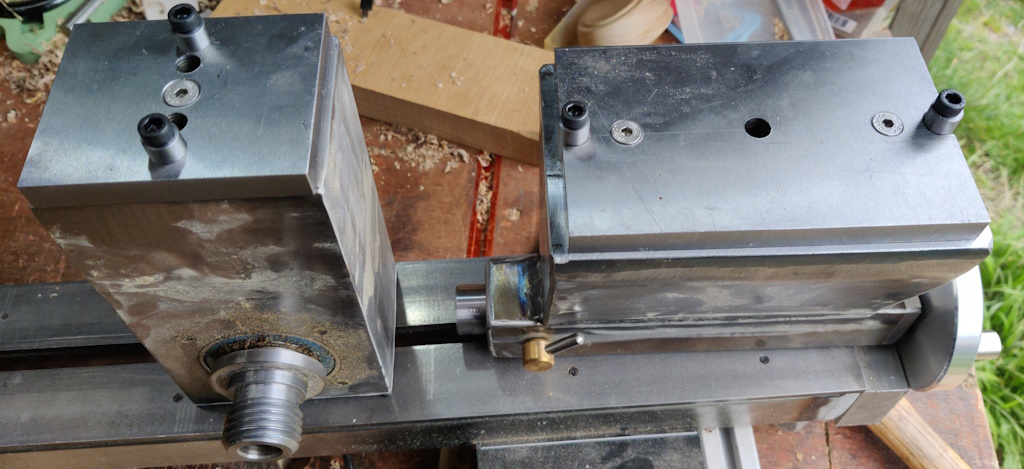

Overall view of the upgraded lathe:

The centre height of the lathe is now 140 mm, allowing a theoretical maximum diameter of 280 mm (assuming the blank was already circular and perfectly centred!)

Page 42 of 65

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page