Woodturning Lathe Build Process

Page 48 of 50

Posted 23rd December 2025

After getting back from the "joys" of Christmas supermarket shopping, I finished off the spindle by cross-drilling the hole for the tommy bar:

Ignoring the minor inconvenience of making the spindle again from scratch once the 50 mm bar has arrived, that's the spindle done.

Rather than dwell on my mistake, I thought I'd get on with the next job: a new lid for the headstock. The current lid is a bit of relatively thin plate with a hole in it (for the tommy bar) and a sliding cover for the hole. The cover can easily get knocked (or vibrated) away from covering the hole, which isn't ideal. When I opened the lid as part of the disassembly of the lathe, the headstock had rather a lot of sawdust inside. I'd like to improve that.

When I made the original lid, I took advantage of the relative flexibility of the thin steel sheet and didn't bother to machine the top surface of the headstock. For the new lid I'd like a flat reference so the first job was to stick the headstock in the milling vice and run an end mill around the top surface:

Next up was the lid, which is going to be made from a big lump of aluminium I found in the skip. The aluminium block was much too large so the first job was to cut a bit under half of it off in the bandsaw. The cut-off bit then got mounted in the mill vice and I used my big flywheel fly cutter to clean up all the faces and bring it to the target dimension. In progress shot:

The fly cutter leaves a lovely finish:

After squaring up all six faces:

I then used a 16 mm end mill to cut a profile into the underside of the aluminium block:

The tallest bit drops down between the two bearing retainers and provides enough material for some screws to come in from front and back (rather than above) so I can use bigger screws (compared to the M3 ones I used on the previous lid). The shallower bit sits fully inside the lid against the edges of the headstock.

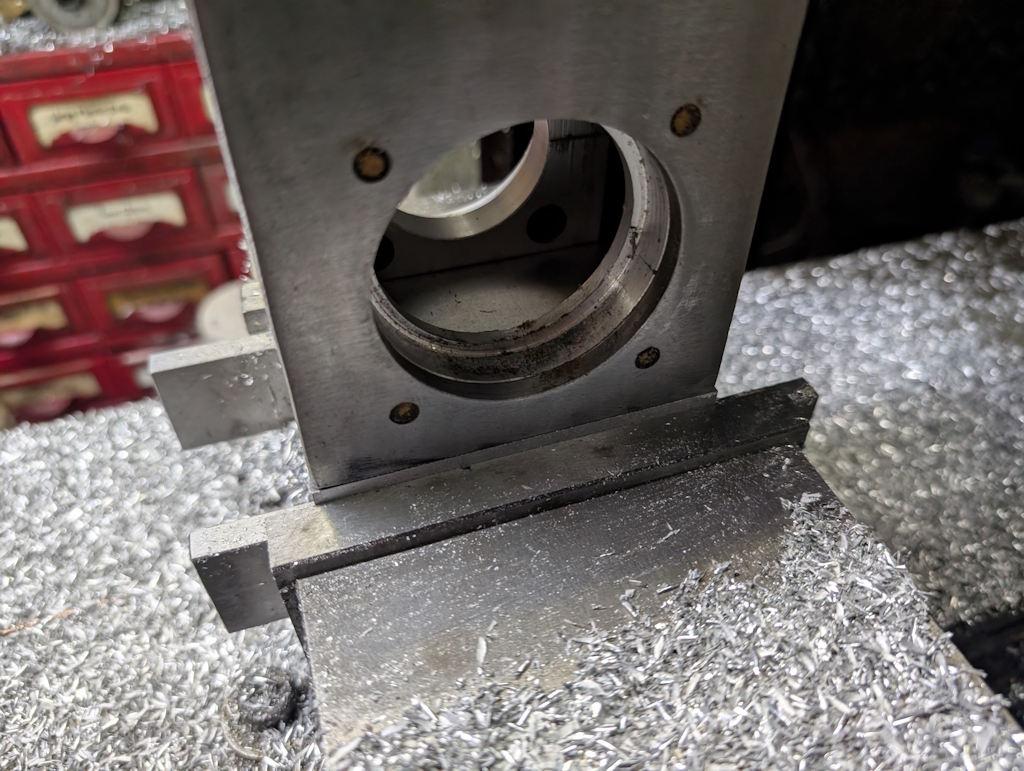

Before finishing for the day, I did a test fit, dropping the headstock (with bearing retainers fitted) onto the lid to check there were no clashes:

Page 48 of 50

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page