Woodturning Lathe Build Process

Page 58 of 60

Posted 9th January 2026

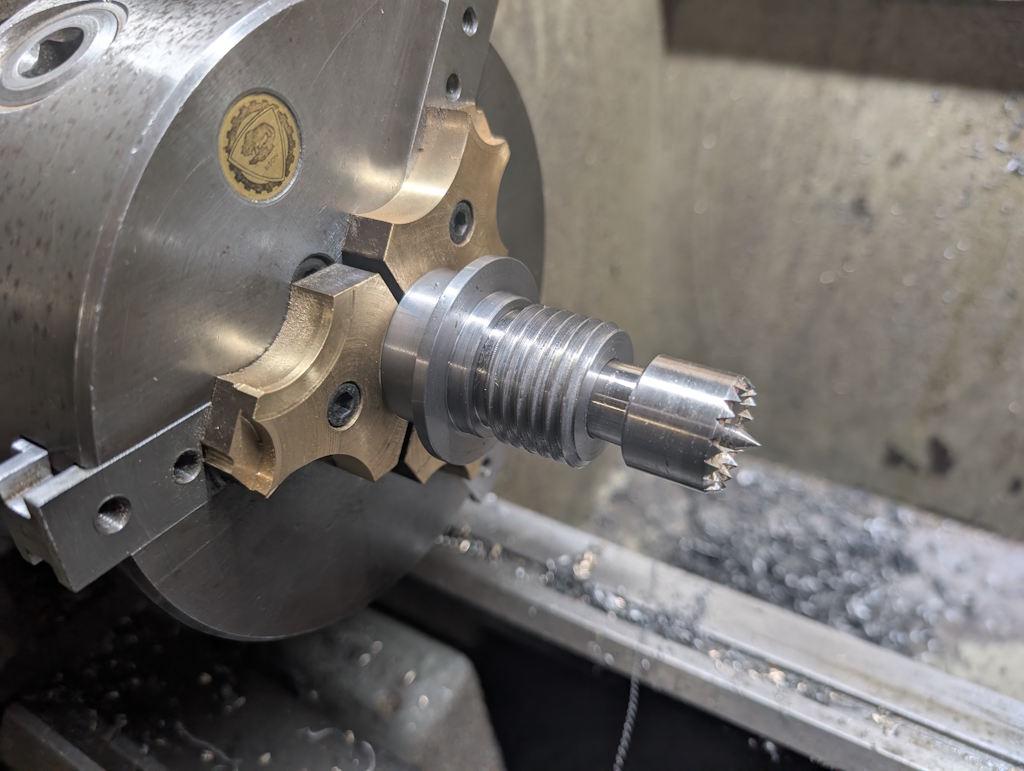

I got on with the spindle today. Here it is after getting the critical outside turning done (i.e. the bearing surfaces and the chuck register):

The rear threads then got turned as before:

Drilling from the rear was done in two stages, a 10 mm drill and then a 13 mm drill:

Once it was in the soft jaws and I'd drilled through and then bored and reamed the Morse taper, it was with quite a sense of relief when I got the hole size about right:

I probably could have gone a bit bigger than that (and hence allowed the centre to go a bit further in) and according to the proper Morse taper dimensions I should have. However, I wanted to err on the side of caution and I'm sure there's plenty of taper engagement for a good grip.

The last thing to do on the spindle was to cross drill for the tommy bar and (in a change from previous spindles), mill a flat for the grub screw in the dividing wheel to bear on:

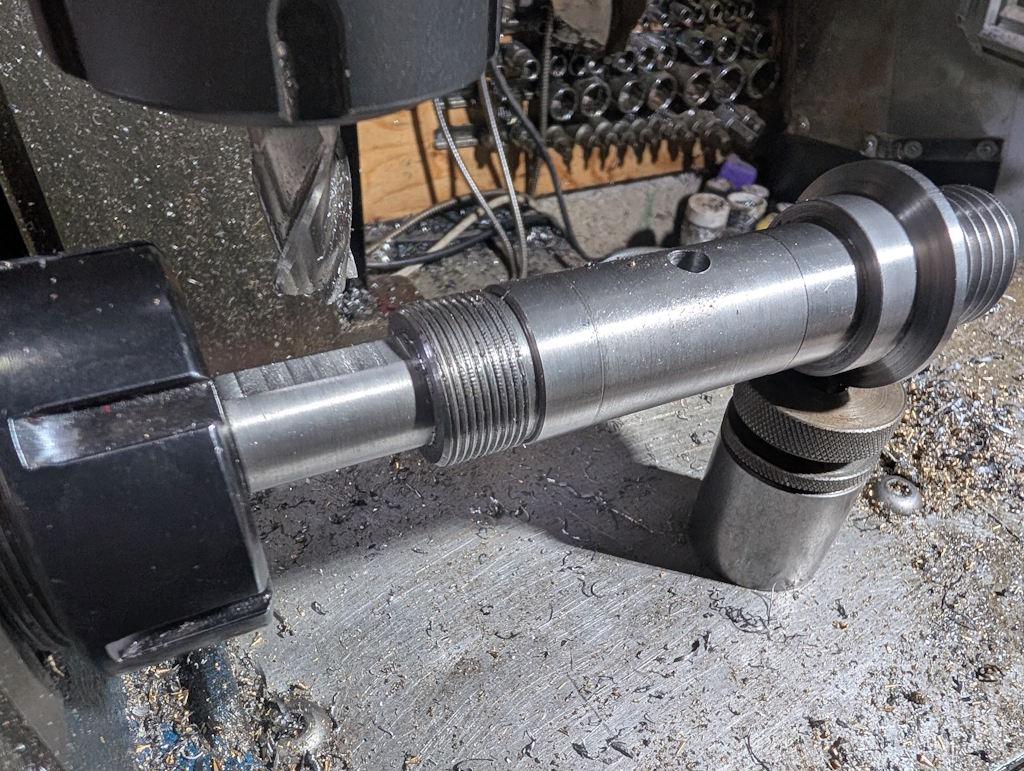

The finished spindle:

Page 58 of 60

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page